Ju-87B-2 Stuka

Brief History:

The Junker Ju-87 was developed as a dive bomber for a design competition in the United States in the early 1930’s. Ernst Udet was a leading WWI ace who was part of the new Luftwaffe and had a strong influence on the aircraft performance requirements that the companies had to meet. In 1936 three German aircraft companies competed for a dive bomber. The Ju-87 was most impressive, executing an almost vertical dive and pulling out of it with ease. The competitor He-118 had separated from its propeller and gear box, which was the deciding factor to award production for ten Ju-87A-0 aircraft. The B-2 version used the Jumo 211Da engine with a pressurized coolant radiator, larger propeller and rear pointing exhaust stacks to increase speed. A small propeller mounted on one or both strut boots created a sound during the Stuka’s dive that came to be a psychological effect on people below within hearing range.

In the Box:

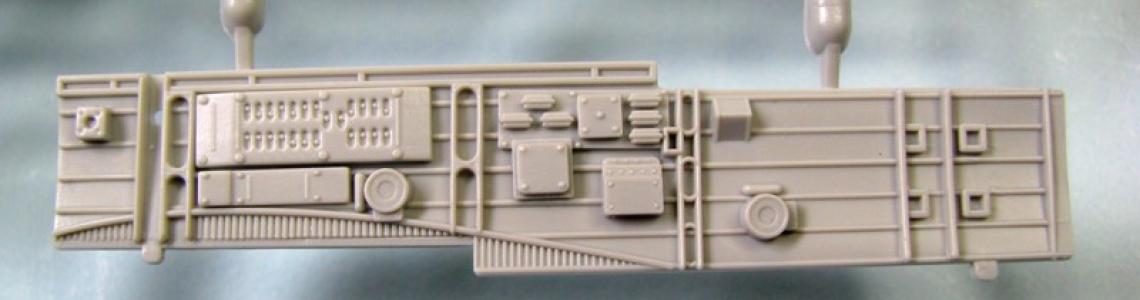

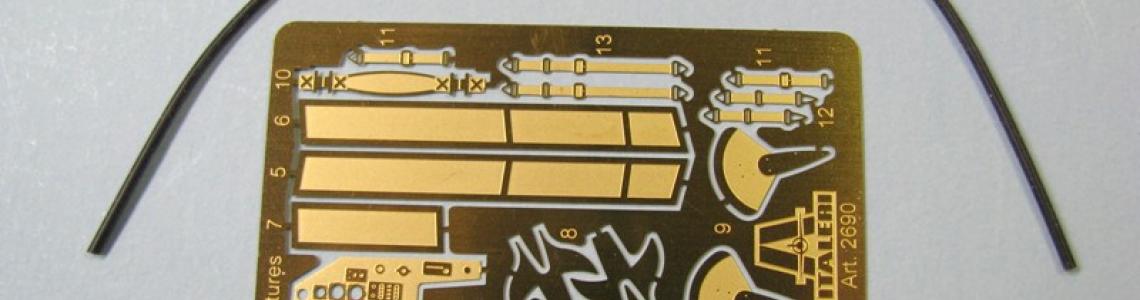

Feast your eyes on the fine detail Italeri did in the tooling of this kit and it begs to be built. Italeri labels this as a new tooling kit and does not appear to be a re-mold of another company. The detail is nicely done with scribed lines and rivet patterns evenly spaced. The clear pieces are thin and clear, but mine were also defective which I will get to in the build process. There is a very nice photo-etched fret for seatbelts, dive angle pieces for the stabilizers, wing walk protectors, cockpit anti-glare screen, and an instrument panel in two parts. What I didn’t like was the gold plated fret. All the parts involved were not meant to be this color. The decal sheet is very nice giving a choice of three aircraft markings, the Russian Front, Balkan Campaign, or Egypt.

The Build: I glued the two part photo-etched instrument panel and painted it RLM02 grey. When dried, I began to dry brush the details with a result that was less than acceptable so I opted to use the decal supplied for an alternate instrument panel. I still wasn’t pleased with the decal. I would rather have had raised instruments on a plastic panel. I assembled the seat with the PE belts supplied and after painting the seat and seat belts completely, set aside until the model was done. I attached all the pieces to the cockpit floor and painted the assembly along with the separate walls with RLM02. A little dry brushing of rust was sporadically applied throughout the cockpit to show the ill kept interior wear that the Junkers received and then applied a black wash to make the details pop. I was pleased with the cockpit results except for the instrument panel decal. It was time to mount the cockpit between the fuselage halves. Test the fuselage halves together around the cockpit for a little filing is necessary to make the two fuselage halves fit without applying some pressure.

The engine went together easily. A nice added touch supplied in the kit is a very thin flexible rubber tube to cut into pieces, adding to the 14 detailed engine parts counting the wide mouth air filter. The engine was painted black and dry brushed with a medium grey. The engine mounts were painted dark grey, attached to the engine, then set aside. Naturally, you wouldn’t have to go through the engine effort if you were closing it up in the fuselage. Since the kit was being reviewed, I wanted to assemble and paint it.

The lower wing is one piece with the ailerons molded attached. Just a note that the Hasegawa wings are molded the same. Before you glue the two top wing surfaces, you have to drill out the necessary holes for bomb racks and dive brake supports. Mating the fuselage and wing assembly together wasn’t a perfect match. As you can see in one of the pictures I took, there was small uneven gap when test fitting these. If you line up the underside wing bottom to fuselage, the contours of the top wing roots would not align properly. Matching the top wing root contours to the fuselage created the misalignment below. I decided to match the top contour wings to the fuselage, which were nice snug fits on both sides, and applied liquid glue. The wing underside had to be filled and sanded.

A note of caution that where the control rods and weights connect to the ailerons, they are glued on a small raised pedestal and have an extreme high chance of breaking while handling the model. Also, the aileron weights under the right wing do not line up well with the holes in the wing surface.

The tire halves are nicely done with the weighted bulge, avoiding the cost of another purchase, searching for them, and wait time to obtain it. Use slow curing glue for the stabilizers and supports so they can be adjusted for alignment before the glue sets. Don’t expect much adjusting as these aligned nicely.

The canopy parts are really nice but one of the rear pieces had a manufacturing defect crack stretching across two panes of glass panels, and the front right windshield had a warped corner (see photo). Trying to get replacement parts from Italeri is impossible. I don’t have a vacuform to remake the parts so I have to live with the cracked piece. Fortunately the warped windshield corner was in the fuselage area where I was able to fill it with putty.

I intended to use the PE wing walk protectors, but decided to use the decal supplied option which is what I did after painting. I thought the 1/48 scale PE wing walk protectors were too thick and better suited if given in a 1/32nd scale kit.

Not until you attach the spinner to the fuselage do you see two major errors. (1) the contour of the fuselage behind the spinner is not correct (see photo). There is an obvious flat surface protruding beyond the spinner diameter that would never be accepted in aircraft air-flow design. I didn’t see this until I finished painting the model and fitted the spinner. (2) Even I saw this, the fuselage nose contour is so out of proportion that correcting the fuselage would have been a beast to tackle. The spinner diameter is not too small. In fact when comparing the spinner to actual Stuka pictures, the spinner is too fat on any Ju-87 version. Sorry but this new tooling needs re-tooling. The Hasegawa kit in comparison has the fuselage nose shape and spinner contour right.

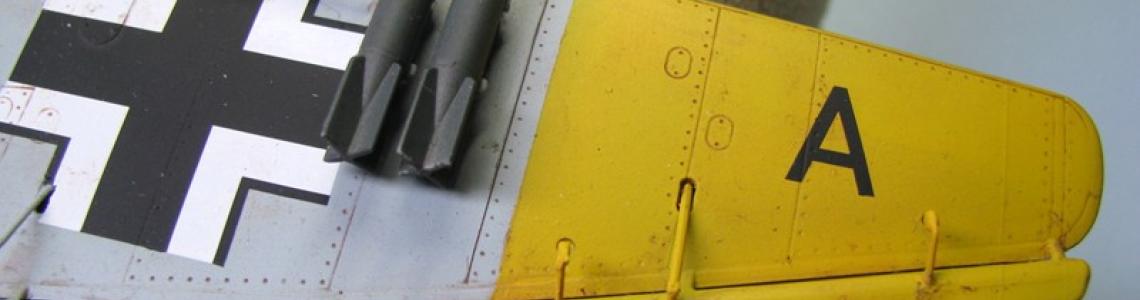

Moving on to finishing the model, I used the Testors Model Master enamel paints RLM04 yellow for the underside wing tips and ID Band, masked off the yellow, than applied RLM65 hellblau for the underside color. The splinter camouflage was painted with RLM70 and RLM71. I allowed each of the colors to dry thoroughly overnight before I masked over them. Then I applied a surface of Testors Gloss Coat and allow that to dry overnight.

This Ju-87B-2 replica has markings produced by Eagle Strike Decals of Gruppen Kommandeur Helmut Bode’s aircraft in June 1942 in Russia. He commanded 3/St.G 77 throughout the Battle of Britain and on into Operation Barbarossa in the Crimea. I normally apply decals with a surface swipe of Solvaset and a touch of water before sliding on the decal. Once quickly set in place, I pat it down with a wet cotton cloth, apply another light swipe of Solvaset, and let dry completely. I used a dark brown acrylic wash (paint, liquid soap, and water mix) over the model reflect how dusty the Ju-87’s were in the summer weather months on the Russian Front. When dry, a coat of Testors Dullcoat was applied.

Many modelers have been using Monofilament fishing lines for rigging and I have heard complaints that various ambient temperatures can cause slight sagging. I have always heated plastic sprue pieces rotated over a candle until softened, then stretched apart for my aerial lines. Gluing them to the model takes patience and sometimes a few times to get it right.

Conclusion: We modelers put lots of time and effort to make a nice miniature replica of the real thing. There are hundreds of models available that modelers wish to build, many duplicated by different manufacturers. This kit has a thirty-five dollar price tag attached to it and I didn’t expect the fuselage nose and spinner to be such a flaw. I am sorry to say that if I were to build another Stuka, it would not make my list.

Thank you MRC/Italeri and IPMS/USA for the opportunity to build and review this kit.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews