HMEE-1 (High Mobility Engineer Excavator)

Description

The HMEE-1 is an armored backhoe loader designed for high speeds in order to self-deploy with military convoys, and capable of towing heavy loads with good off-road mobility. It is based on technology from the JCB Fastrac tractors. The maximum speed of the HMEE is 60 mph on improved roads and 25 mph on secondary roads. Wikipedia

Panda’s kit is the -1 version of the HMEE with armored cab, front clamshell bucket/dozer blade, and rear backhoe. The kit includes an engine, but no transmission transfer case. The kit’s hydraulic cylinders will move, the front clamshell is openable, and the bucket arms raise and lower. The rear backhoe folds open/close and rotates and the rear outriggers are movable up or down. It might be possible to install the wheels so they rotate but I did not attempt do so. Panda provides some of the hydraulic lines molded on the cylinders and booms but does not provide the rest of the hydraulic piping. The engine cover and cab door are molded shut and not openable without major surgery

The HMEE kit appears to be very accurate compared to online photos and JCB’s literature

Kit Contents

The kit comes on five large sprues molded in a dark yellow plastic, separately bagged cab and hood sections, four vinyl tires, small photoetch fret, small decal sheet, and one clear plastic sprue with the windows and light lenses. The plastic sprues are separately bagged, and the photoetch and decals sheet are in a separate Ziploc bag. Most of the plastic pieces have some minor mold flash and there are some injection points that need to be trimmed off. The flash has affected many of the slots that need to be opened up before the tabs will fit. Panda has placed many of the sprue attachments on the ‘back side’ of parts rather than the edge, which makes cleanup easier without damaging the edge. The parts have very good detail.

The photoetch is fairly thin and includes vinyl on both sides for protection and preventing parts from getting launched. The photoetch pieces are small and finely detailed screens, handles, and tie downs. There are minimum sprue connections for the PE parts which helps with cleanup.

Instructions come in a 7 1/2 x 11 in. stapled booklet with 16 pages and 17 assembly steps. The assembly steps are exploded diagrams that for the most part are very clear. Study the drawings carefully as some parts are difficult to see, and some are not numbered. The instructions also include a diagram of the sprues to locate parts. A separate small poster is provided with a color copy of the box art on one side and color profiles on the opposite side. Gunze Sangyo Mr. Color paint colors are called out on the profiles although there are only two colors, sand yellow and tire black. There are no detail paint callouts on the assembly diagrams so other references will be necessary.

The small decal sheet provides a decal for the dashboard, instructional labels, and warning labels.

Assembly

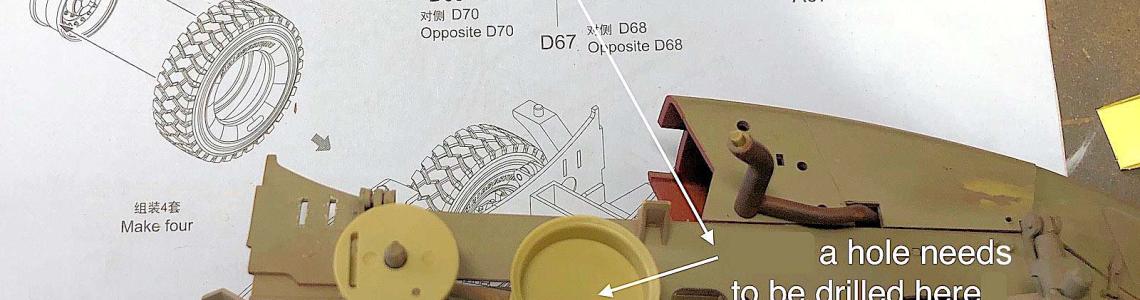

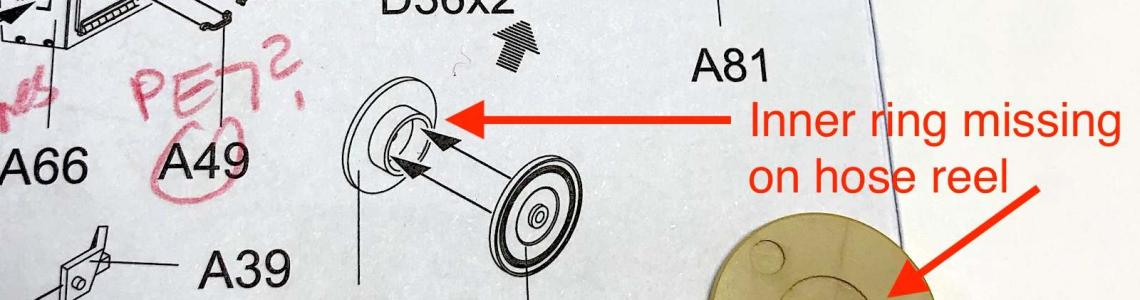

Assembly of the Excavator goes fairly well, but there are some challenges. Many of the slots are too small for tabs due to minor amounts of flash and need to be opened up or the tabs trimmed slightly. The same with holes for mounting pins, like on the hydraulic cylinders, that need to be drilled out. Many of the parts with joining halves like the bucket arms don’t fit tight together and require filling. There are some errors in some of the parts. In step 6 the inner wheels do not have the center mounting hole, requiring one to be drilled. In step 15 the hose reel, part B49, does not have the inside space ring, requiring one to be fabricated. With some careful work however, the kit does make a fine model, with good detail and workable arms & buckets.

Engine Assembly

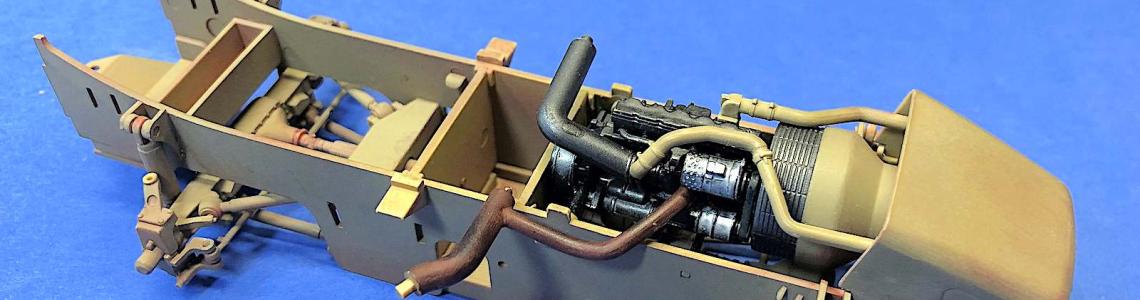

The engine parts provide nice detail for the excavator engine, although the engine will only be visible if the removable hood is cut off the cowling and left off. Panda does not include the transfer case, which is ok as it would be totally enclosed between the two chassis bulkheads. There are no detail paint colors to help with finishing the engine. The instructions show installing the fan shroud to the front of the engine but the fan is a loose fit inside the shroud. It is easier to mount the shroud to the front bulkhead, part B16, rather than to the front of the engine. When installing the air intake tube part A69 to the engine, dry fit the engine in place with the engine cover to check for the correct position while the glue sets.

Chassis Assembly

The next series of steps, two through six, assemble the excavator’s chassis. Wait until the engine is installed in the chassis before assembling bulkhead A73, which will make the assembly much easier. Likewise, dry fit the engine cover when gluing the exhaust pipe part B10 to the engine to get the correct location. I left the struts, parts D41 and D42, free to rotate until after the axles were installed.

The axle hubs, parts D27, D28, D73, and D75, are separated into top and lower halves which complicates assembly. The top and bottom half for each axle should be assembled together and the axle ends aligned before the glue sets. The suspension piston parts D64 and D65 were very tight fits so I thinned the ends to make them fit easier. Support struts for the front fenders are shown to be installed in step four. Part B23 goes on the right side and B22 is not noted but goes on the left side. There are no slots for the tabs on the fender struts, so I cut the tabs off. Refer to step five for a better drawing showing where the struts are assembled.

The body panels for the underside of the vehicle are installed in step three and fit nicely. Step four shows assembly of the engine cover. There is no provision for an open cover as the engine cover is molded in one piece. Exposing the engine would require separating the halves of the engine cover, cutting along a curved line. If installation of the engine cover is delayed, it must be installed before the excavator cab is glued to the chassis.

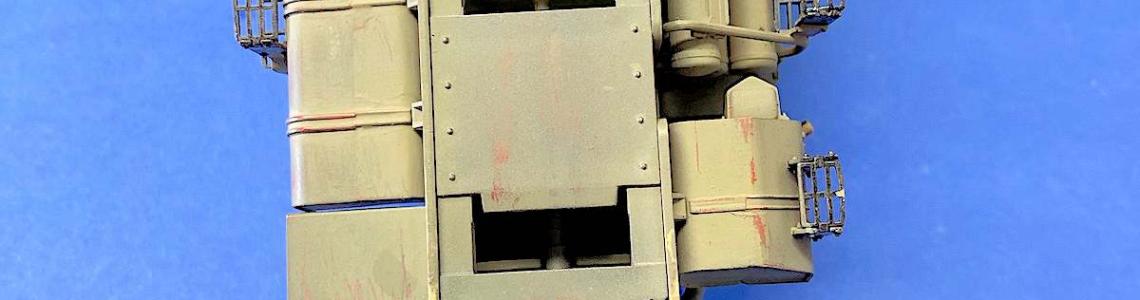

Steps five and six assemble various tanks for the side of the excavator. Most of the tanks are assembled in halves and the resulting joints were not very smooth and required filling. When assembling the tank and step frames, parts A6 and A7, dry fit them to the chassis to get the correct angle for part A7 because they are at an odd angle

The wheels for the excavator are assembled in step six. The inner wheel half that came with my kit, part D67, did not have the center hole as shown in the instructions and required for assembly of the wheels. I drilled out a hole to allow the wheels to be assembled. (Oddly, another kit purchased separately had the correct holes) The wheels include a retainer cap, part D38, that might allow the wheels to rotate if the cap is carefully glued to the axle stub. If this is desired I would suggest assembling the inner wheel half to the axle before assembling the outer half of the wheel. This would allow more careful gluing of the cap. I did not need the wheels to rotate so I omitted the cap and glued the inner wheel directly to the outer wheel.

Assembly of the interior and cab for the excavator are detailed in step seven. The interior includes a driver and commander seat, instrument panel, and drivers console. The foot pedals do not include the detail of the tread or perforations shown on the instructions. There isn’t much detail to the seats, seat belts, or other hardware. A decal is provided for the gauges on the instrument panel but is not indicated in the instructions. The decal is one piece for all of the controls but is better cut into individual pieces to allow the decal to settle down. The latches on the front of the cab sides don’t have the detail showing in the instructions. The interior of the cab does not have much detail, but then it is barely visible through the windows and the cab door is not openable.

Step seven also shows installation of the front and rear windows, but I installed all of the windows at this point to facilitate painting. Some trimming of the window openings was required to get the clear plastic windows to fit properly.

Step eight assembles the cab body to the chassis of the excavator. The tabs and pin holes needed to be cleaned out for a good fit, but the cab fits nicely to the chassis.

Hydraulic Lines

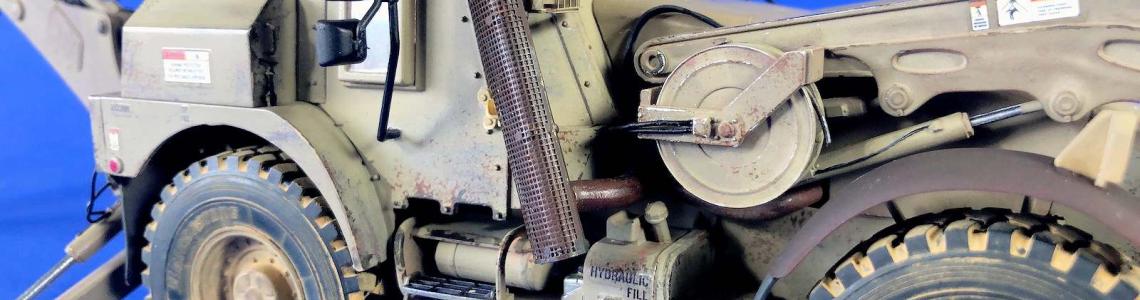

Panda includes some of the hydraulic lines and piping molded onto the parts for the outriggers and front bucket arms. The hydraulic piping to the hydraulic cylinders is not provided and needs to be added separately for a complete hydraulic system. I found some references for the piping online but had to make some guesses also. I used 28-gauge wire for the hydraulic piping. Panda provides the reel for hydraulic lines on the right side of the vehicle but does not provide any of the piping or fittings. Parts B31 and B28 for the rear bucket arms suggest connections for the numerous hydraulic lines to the arm and bucket. I cut off the stub fittings and drilled holes to run wire for the piping. In step 15, part A38 also provides connections for hydraulic piping, which I drilled out to terminate some of the piping from the bucket arms. Adding hydraulic piping provides considerable detail and realism to the kit but requires a fair amount of work to run the wires, and in my case guessing where the piping runs.

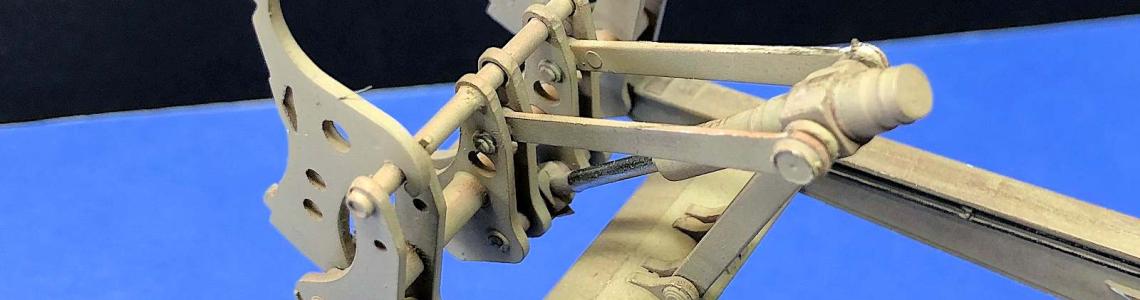

Step nine assembles the brackets, hydraulic cylinders, and piston rods for the front bucket. The instructions indicate those parts not to be glued to allow the bucket to move. The exact location of the frames A29 - A30 is not clear as there are no locating pins or tabs. I measured and centered the frames on parts D1, based on the spacing of the hydraulic piston B39. There are some ejection pit and marks on these parts that should be cleaned up as they will be visible. The hydraulic cylinders such as A45 are nicely molded in one piece that is hollowed out for the piston rod. This eliminates gluing the cylinders in halves and eliminates the longitudinal joint, however there is a mold seam that will need to be cleaned up.

The rear outriggers and front forks are assembled and attached to the body in step 10. The halves of the bucket arms do not fit tightly and require filling. There are some sink marks in the parts that also require filling. I left the outriggers and front bucket arms loose until later to avoid damaging them during assembly. Step 11 shows installation of the front fenders, but I left them off until the last thing as they are mounted very fragile.

The backhoe bucket and arms are assembled and attached in step number 12. Panda indicates parts not to be glued to allow the bucket and arms to move. Parts A22 and A23 should not be glued but will be loose enough that they fall out occasionally during handling. The top plate on the backhoe base is not numbered but is part A28. I found it easier to install the backhoe base to the rear of the chassis before attaching the backhoe arms. I attached wires to the backhoe arm for piping to the hydraulic cylinders, then through the base parts B28/B31 to a hole in the back of the chassis.

The front bucket is assembled in step 13 but here Panda does not indicate those parts not to be glued. Parts B29 and B30 should be glued to the bottom of part B18, not to the blade B19. This will allow the clamshell bucket to open and close. The holes in the hydraulic pistons and cylinder mounts are too tight and should be drilled out to allow the clamshell to open and close easily.

The front headlights are assembled in 15 with photoetch and plastic. The photoetch is quite delicate, and it’s difficult to get the light assembly installed within the photoetch bracket. I found it easier to glue the plastic light body into place prior to bending the photoetch. I left the screens open to allow installation of the clear light lenses after painting. Additional photoetch tie downs are attached in this step but not all locations are shown. There is an additional one on the side of part A66 is shown on the box art. The instructions show installing a plastic handle to part A66 but there is a photoetch handle left over so I used that.

Step 16 installs the muffler, exhaust, and air intake piping to the sides of the cab. Top armor plate is also added to the cab as well as a rooftop air-conditioning unit. The rooftop air-conditioning unit is well molded but could have used some photoetch grills. The mounting holes on the cab for the air intake piping are in the wrong location and too far apart so I cut them off. Test fit the muffler bracket part A40 before gluing to get the correct orientation. A storage box, part C13, is attached to the vehicle with some nicely molded-on grab handles. Step 17 installs the top protective frame for the air-conditioning unit. The delicate rearview mirrors are also fabricated and attached in this step although I left them off until the very end to avoid breaking. Clear plastic pieces are not provided for the rearview mirrors, which is strange considering the other considerable detail with this kit. I painted the mirrors with Alclad black chrome and covered them with Future to simulate the mirrors. The brackets for the mirrors, B8 and B9, are reversed in the instructions.

Painting and Marketing Guide

A separate page in the instructions provides a color copy of the box art on one side and the painting and marking guide on the opposite side. The Mr. Color paint colors called out are just sand yellow for the excavator and tire black for the tires. The rearview mirrors, fenders, lights, and air intake are shown as black which is similar to reference photos. The small tank on the left side in front of the fuel tank does not have a color called out. I used a gun metal which is similar to online photos.

The decals are mostly warning and instructional labels. There are two decals number three for the front lifting hooks that are shown on the marking guide but not called out. The decals come off the backing fairly quickly and lay down nicely. There are several decals left over and I am guessing they could be for the interior of the cab which did not include decal callouts. I couldn’t find any online references showing decal placement in the interior.

Summary

Panda’s HMEE-1 is a nice kit that has good detail, can have moving buckets and arms with careful assembly, but is a difficult build. The part fit has some rough areas requiring patching of joints and fixing connections between parts. There are errors in the instructions and some of the parts have defects too. This is a kit that would be very difficult for beginners or those with limited modeling experience. More advanced modelers willing to fix the problem areas should be able to produce a very nice model.

Thanks to Panda Hobby for producing this kit of an interesting subject and providing the review sample to IPMS.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews