Hitachi Zaxis 135US Excavator

This is not a highly-detailed kit, but can be an entertaining build for both less experienced and more advanced modelers. Less experienced modelers will enjoy the ease of assembly, and can build the kit without painting. More advanced modelers looking for construction equipment will find the kit to be an opportunity for some extreme weathering.

Background

This is the second kit Hasegawa has produced based on the Hitachi tracked excavator. The first was the Double Arm Working Machine Astaco Neo released in 2015 and updated in 2017 with new parts. This new Hitachi Zaxis kit retains the grasping claw from the Double Arm kit, but adds an excavator bucket and dozer blade as additional options.

The Zaxis 135US-6 excavator is used by contractors needing a tight tail-swing radius to work in confined areas around obstacles. The excavator is equipped with an Isuzu engine.

Kit Contents

The kit comes on multicolored sprues so it is possible to have a nice-looking model without painting. The kit has 175 parts including the following:

- 5 gray plastic sprues for the base, running gear, and cab

- 1 gray plastic sprue with driver figure.

- Black rubber sprue with rubber band type treads and hydraulic hoses.

- 1 clear plastic sprue for the cab windows.

- Length of vinyl tubing for hydraulic lines.

- 1 light gray sprue for cab interior details.

- 3 orange plastic sprues for excavator arms and bucket.

- Decal sheet.

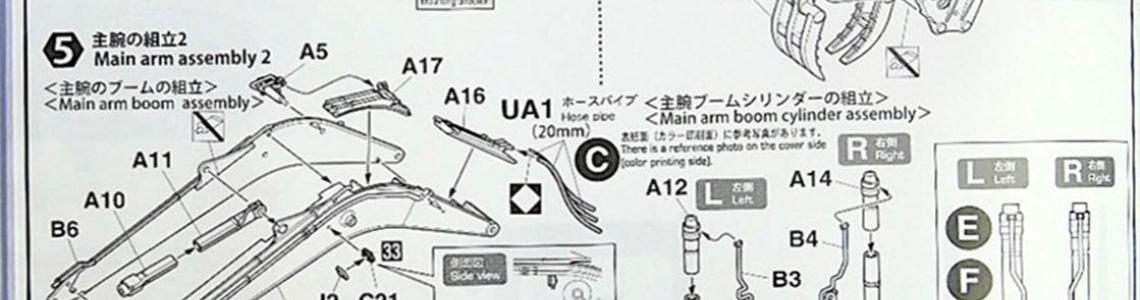

The instructions are on a 7"x10" folded sheet with 14 assembly steps, color profiles, background information, and layout of the sprues. The instruction diagrams are very clear, but scattered all over the page. Make sure to look at all the diagrams on each page to understand the sequence in placing of parts. Hasegawa provides a lot of information crowded on to the instruction sheets. The back of the instruction sheet has photos to help with installation of the hydraulic hoses, and color profiles of the excavator to help with decal placement.

Paint colors are called out in GSI Creos Aqueous Hobby Color and Mr. Color paints.

The parts have good detail and the fit is excellent. The plastic is fairly soft, has virtually no flash, but there are numerous pour plugs and sprue connections to clean up. There are only a few small pieces such as the hydraulic cable guides and connectors. The various subassemblies are grouped on sprues so there is not a lot of shuffling between different sprues.

Assembly

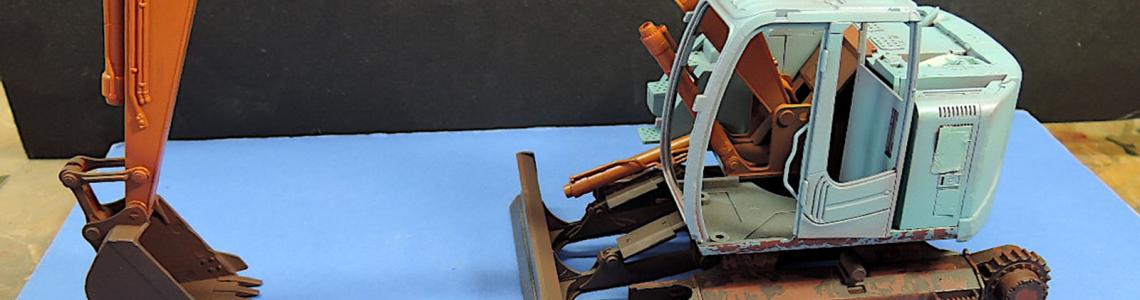

Assembly starts in steps 1 through 3 with the male operator and cabin for the excavator. The operator has 8 parts including hard hat. I didn't install the windows on the cab at this time, but waited until after painting and weathering. The cab parts fit together very nicely. There is an option to have the cab door either open or closed. I then jumped ahead to steps 8 and 10 to complete the rest of the upper rotary body. The instructions state to add 30g to the rear counterweight on the excavator to offset the weight of the bucket and arms. The parts again fit together very nicely. This is a good time to paint the interior of the cab and install decals before the cab gets closed up. I had decided to paint and weather the excavator as an abandoned rusty hulk so I started painting and weathering the interior before closing the cab.

I then went back to steps 4 through 7 to construct the main arm and bucket. There are two options with the kit for either a bucket or the forked grapple, and I decided to use the bucket with the dozer blade. The arms go together very well and the parts are molded to conceal the seams to minimize filling and patching. The hydraulic cylinders are cast as one piece to avoid a center seam.

The illustration diagrams are a little confusing with all of the arrows to locate parts, so be careful to know which parts are not to be glued to allow the arm and bucket to move. There are small pins, part L3, with caps, part Y3, that allow the bucket to rotate. I could not get them attached securely without gluing the whole joint so I just left off part Y3. With care assembling the joints, the arm and bucket will move freely.

Molded rubber cables are provided for connections between the hydraulic pipe sections. The pipe should be painted the same color as the arms, while the hoses are to be black. I left the hoses off until after the arm was painted and weathered.

I primed and painted the arms with Mission Models acrylic primer, and a base coat of light rust. Mission Models highway yellow was applied over hairspray and chipped to show wear. AK Interactive rust washes and Vallejo rust was applied with a sponge. MIG Europe dust pigment was applied to create a dusty look over the rust.

Step 9 is the dozer blade assembly. There are a couple small parts for the hydraulic hoses to connect to the dozer arm cylinders, but otherwise the parts go together nicely. I roughened the dozer blade to reflect wear, and then painted it with Alclad chrome to represent the polishing from use of the blade. A rust wash was then an applied to the chrome blade.

The cab and hydraulic arm are attached to the rotating body in step number 11 and fit nicely.

Step 12 assembles the lower traveling body, sprocket wheels, and treads. Poly caps are used to allow the drive sprockets to rotate. Small springs are installed in the idler wheels to take up slack in the tread. Nothing retains the idler wheels until the tread is installed so I temporarily taped them in place. The upper and lower halves of the lower body have marks denoting the front of the vehicle. It's a good idea to mark the front of the lower body as these marks will be hidden once they are assembled.

The tracks are the rubber band type fastened with superglue and have fair detail. The treads bow upward when installed, so I used epoxy to mold in some droop and anchor them to the idler wheel. I primed the treads with Vallejo track primer acrylic paint, and weathered them with Vallejo and AK Interactive rust paints and washes, followed with some MIG rust and dust pigments.

Summary

This is an easy kit to assemble and produces a nice-looking model. It’s easy enough for beginners to put together and get a nice model, even without painting. The excavator can be an interesting piece of construction equipment for experienced modelers to paint and weather.

Thanks to Hasgawa for producing these nice models of construction equipment and providing review samples to IPMS. Thanks to Dave Morrisette and Dick Montgomery for letting me review this kit.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews