HH-60H 'Rescue Hawk'

The HH-60H “Rescue Hawk” was first developed in the 1990s as a rescue variant of the SH-60F “Sea Hawk”. Two versions were developed at this time, the HH-60H for the US Navy and the HH-60J for the US Coast Guard. For its search and rescue role it is equipped with long range fuel tanks, a FLIR Sensor and a few defensive countermeasures. It can also support anti-surface operations by mounting up to 4 AGM-114 Hellfire missiles on special pylons. Since it is based on the SH-60F, the HH-60H retained the ability to operate from small flight decks and be folded up to fit in deck hangars. It’s last year in service with the Navy was 2019. This new kit from Kitty Hawk is the latest in Kitty Hawk’s line of Seahawk variants. The previous version being the MH-60R.

The basis for this release is the new tooled kit from Kitty Hawk released in 2019, MH-60L Blackhawk. Several new sprues add parts to cover the many options available for this kit. The kit comes in a large and very colorful box that features an image of the aircraft in standard all grey camouflage. Included in the box are 13 sprues of very light grey styrene, 2 clear sprues, 1 PE fret, separate parts for the main fuselage and a decal sheet. Many of these parts will not be used in the build as there are a ton of extra parts and weapons included from previous versions.

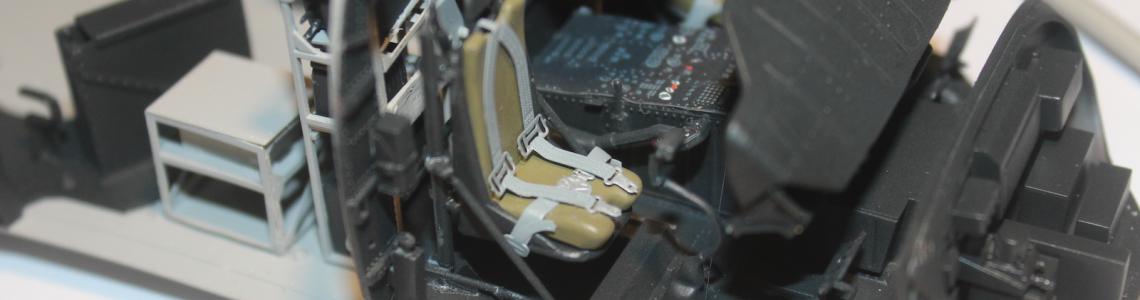

The first few steps are dedicated to the cockpit interior. The detail here is up to Kitty Hawk’s normal standards. Fine moldings with plenty of detail. The callouts here for the required colors are not complete, in step 1 the cockpit is black but the cargo area should be FS36440. The seat frames in step 3 should be black and I painted the seats Tamiya Khaki. In step 4, the frames should be FS36440 and the seats were painted Tamiya Khaki as well. I no issues with the detail, molding or fit of the parts in these steps.

Steps 5 and 6 cover what appear to be some radio and electronic equipment specific to this version. The fit and details of these parts is quite nice, including the PE. However, the color callouts are all wrong. All of the parts in Step 6 should be FS36440 according to my references and the instructions list them as black. They also have all parts in Step 5 as black, but in most cases this should only apply to the equipment on the shelves. All of the shelves and the two upright parts, HH45/46, should be FS36440. Lastly, the fire extinguisher, part HE8, needs to be red.

Steps 7 and 8 complete the rest of the forward cockpit area. The detail on the parts here is pretty good, with well modeled detail and good fits. The colors are correct, with callouts for black and the decals fit pretty well over the molded detail. You will have to use Micro Sol to soften the decals and possibly trim them into sections to assist in the fit. In step 9, the upper controls and the rear bulkhead are completed. There is a missing callout for the back of the bulk head, this should be FS36231. The detail here is also pretty good and the decals are nice as well. However, not all the switches were covered but the decals, so I highlighted a few by dry brushing with flat white, red and yellow.

Steps 10 through 12 continue the assembly of the interior. In Step 10, part HB24, needs to be painted FS36231. In this step the seat belts are also installed for the pilot and co-pilot seats. These are nicely handled in PE but the instructions aren’t very clear on how to install them, so check you references. Also there are no color callouts for them, I used Tamiya XF-54 with Silver Chrome for the buckles. I had no issues with step 11, everything fit very well. The only issue that I had in step 12 was the color call out, the instructions again call for black but the correct color is FS36231.

Next up is the build and instillation of the optional 50 caliber gun in step 13. Mostly, the parts in this step go together just fine and the detail is good. I did leave the gun and mount off until final installation as it does hang out the open door and will be easily broken. The only issue that I had here was with the feed belt for the .50 caliber, this is a PE part that you are required to fold and then mold into position. This requires a complex set of curves that I could not make work in PE. You may be able to get this to work by heavily annealing the PE but for the most part the thin PE tends to break. I would absolutely recommend replacing this part with something molded in flexible resin. Lion Roar makes a very nice set in 1/35 scale that you should be able to source.

Steps 16 through 17 cover the final assembly of the interior of the fuselage and closing the main section of the fuselage around it. The only issue I had in step 16 was with the paint call outs again, the instructions call for black again but the correct color is FS36231. The fits here are pretty good except with the rear bulkhead of the cockpit, in my example this was a little warped and I had to bend it back into position. You will need to install the rear landing gear while closing up the outer fuselage, I prefer to install it later for easier painting but that is impossible on this kit. Also I left the wheels and tires off until final assembly.

In Step 18 there are two parts, drilling holes for exterior details and closing the fuselage around the interior. Both of these parts have issues, for the holes it isn’t always very clear where to drill the hole. The instructions are not very clear, so you needed to check your references and do some dry fitting of the parts. Second, the bottom of the main fuselage is a pretty bad fit. I ended up with a pretty big gap that took a lot of putty to fill in. This is partly due to warped parts, both halves of the fuselage in my kit curled in slightly. It also could possibly be due to inference from the interior parts. I had to spend quite a bit of time working on this seam and you will have to be careful, there is a lot of easy to ruin detail on the underside of the airframe.

Next up are the engines, this kit does contain the parts to make some very nice representations of the T700 engines but there are some minor issues. For the most part the parts in step 19 are well detailed and molded. I had no major fit issues either but I did have an issue with parts F59/F60. These parts support the engines and are handed, though the instructions give no indication of this. Part F60 must go on the outboard side of the engine and F59 must go on the inboard side, this is because the other end of the part needs to attach to the fuselage. Also for both engines, part F58 on both sprues was molded short, one of the pipes on it is way too short to attach to the mounting point. Next, I found that part F57 interferes with the fit of the engine housing doors, so I felt that it was best to leave it off. Lastly, in step 20 parts HE9 and HE10 are swapped in the instructions.

I had no further issues with the next few steps but in step 23, I painted the top of fuselage black and part C44 Metalizer Steel. I also left the assemblies from steps 21 and 22 off until after final painting. In step 25, I left the E1/E5 assembles off until after final painting as these would be able to be seen through the intakes. This turned out to possibly be a mistake, I had huge fit issues between these assemblies, C44 and the engines. I ended up having to shave a huge amount of material off of them and I never got the fit right. It is much easier to install them at this stage but masking could be tricky, I painted them Metalizer Steel based on my references. Finally, I left the doors off until after final painting in this step.

Next, I had further fit issues with the engine hatch covers, parts HD31/HD32. There were gaps around these parts that required some minor filling and sanding. I left the light from step 30 off until after final assembly. The exhaust covers in steps 31 and 32, required some filling to hide some seams as well. I painted the insides of these covers black and left them off until after final painting.

Steps 33 and 34 cover the assembly of both of the engine intakes. I had some minor fit issues here with some very minor seams that were fairly easy to correct. I chose to paint in inside of the intakes the same color as the fuselage based on my references. The hoist in step 35 is nicely detailed with no major issues but I did leave it off until after final painting. I did have a lot of trouble attaching the intakes to the fuselage in step 36. According to my references there is supposed to be a small gap around the diffuser plate, but I had a lot of trouble getting everything lined up. Especially with my fit issues from step 25. A lot of filler was used here to fill some gaps where these mounted to the rest of the engine housings. I installed part HH65 but left the doors off until after final painting.

Next up were the cockpit doors. These are nicely designed and molded with no real issue. I did leave the handles and mirrors off until final assembly and remember to paint the side of the door black to match the rest of the cockpit. Steps 40 and 41 cover the assembly of the front landing gear. I had no issues with these steps at all and only left the wheels and tires off until final assembly.

I had no issues in steps 42 or 43 and the next issue I had was in step 44. Parts HF13 and HF11 are some form of antenna; unfortunately they both have square attachment pegs. This requires some modification of the drilled holes from much earlier in order for them to attach correctly to the fuselage. In step 46 I did leave parts C27/28 and C20/21 off until after final assembly. In step 47, the optional mini-guns are assembled. There are two options for assembly and as I intended to use the .50 caliber machine gun from earlier, I only assembled the option from step 48. I had no major issues with these steps except with PE44, this is the part for the very end of the barrels and it is supposed to be round. However, in practice the slits in the parts make it quite difficult to roll these parts into a circle well without annealing.

The next area that I need to mention is in step 53 with the drop tanks. These both needed some sanding and filling to fill some seams. I also had some minor fit issues with them in final assembly, the right drop tank needed one of the pins to be removed in order to allow it to attach to its pylon. In step 54, the tail assembly is completed. The only issue I had here was with the main tail assembly, there were some serious seams that needed to be filled and sanded to hide the joint in the parts. Lastly, I intended to fold the tail so I left the horizontal tail planes off until final assembly.

There were no issues with the tail rotor in step 55. Step 56 covers the assembly of the main rotor. The detail here is pretty great, the molding is good and all of the fits are awesome. Also, it does look pretty impressive when completed. The top part of the rotor and the rotor blades themselves were painted FS36320. The center drive shaft and the lower parts were painted Metalizer Steel. The main issue that I had with this step was attaching the rotor blades to the central part of the rotor. These are designed to move to allow the blades to be folded, on my example several of the pins that attach the rotors to the central part of the rotor were molded incorrectly or missing. These pins are already fragile, so with the missing pins, I had a couple blades break off during handling.

I left the last 4 steps until final assembly. These cover the installation of the tail, the rotor assembly, and the blade locking mechanism. I intended to display the aircraft with everything folded, so in final assembly I had to add the rotor locks and display the tail folded. I had a number of issues with the tail attachment in step 57. The hinges are very fragile and one of my hinges was molded far too short. This assembly was so fragile that I had to reinforce it with scrap PE to avoid the tail falling off. The horizontal tail planes were also very fragile, they needed multiple rebuilds and PE straps to hold them up. The rotor locks have no paint callouts but according to my references they need to be painted red. They were also a pain to assemble. There are no mounting holes for them on the fuselage, just some small rings molded into the skin. Also they are flush mounted, so take your time and use super glue to give everything extra strength.

Moving on to the painting and decals. There are four marking options, two in different two-color camouflages, a dark green option and an overall grey. I chose the overall grey for HS-3 ‘Tridents’ but there is an issue with the scheme here. The instructions call for overall H73 Aircraft Grey and this should actually be a tricolor camouflage. There are plenty of references online for this but the underside should be FS36375, center should be FS36231 and the top should be FS36320. I used all Model Master enamel paints for this, which are unfortunately being discontinued. I had no issues with the decals for this kit. The register is great and they lay down perfectly over Pledge Floor Gloss.

This is an awesome kit. The instructions only have minor print issues and the only major fit issues are with the engines and the main fuselage. I had a great time with this kit and minor issue aside it was very satisfying to build. I would definitely recommend this kit to an intermediate modeler with some serious shelf space and an interest in modern US navy helicopters. This is not a small build at completion. My thanks to Kitty Hawk and IMPS for giving me the opportunity to review this kit.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews