Hannover CL.II Part 2

As with most kits, the Hannover CL.II’s instruction book focuses first on assembling the cockpits, and the assembly sequence, although involved, is very straightforward. But, before anything is assembled, the instructions guide the builder to paint the sidewalls and all of the various cockpit components according to the color callouts provided on pages 4 thru 7. Because there is much to be seen in the Hannover’s cockpits, painting the small details will require some time and patience. However, I personally found the experience to be both educational and enjoyable. In my opinion, building a first Wingnut Wings kit probably will prove to be a very different experience for model builders who are accustomed to assembling other mainstream plastic model kits. Looking inside a WNW kit box, a builder will find both a plastic model kit and an education rolled up in a brilliantly engineered package. There is no doubt that a finished product will be the goal, but the building process may prove to be the real reward if the builder is open to learning new techniques, willing to follow precise assembly sequences, and not in a great hurry to reach the finish line.

The instructions list the paints available from Tamiya, Humbrol, and Misterkit that match the color callouts. But, I used Tamiya and Gunze Mr. Color because I prefer to work with those paints and I know both brands will go on smoothly in thin coats, cover well, and dry quickly. And, I did not find it difficult to match Mr. Color paints to the specified colors. After pre-painting the appropriate base color on everything, I added some wood grain texture to the wood parts with streaks of W/N oil colors, followed by a glaze of Gunze clear orange for a realistic wood grain. Then I dry-brushed highlights on the various “metal” parts. Small details were hand-brushed with Vallejo acrylics using a 10/0 “spotter” paintbrush (and sometimes a sharpened toothpick).

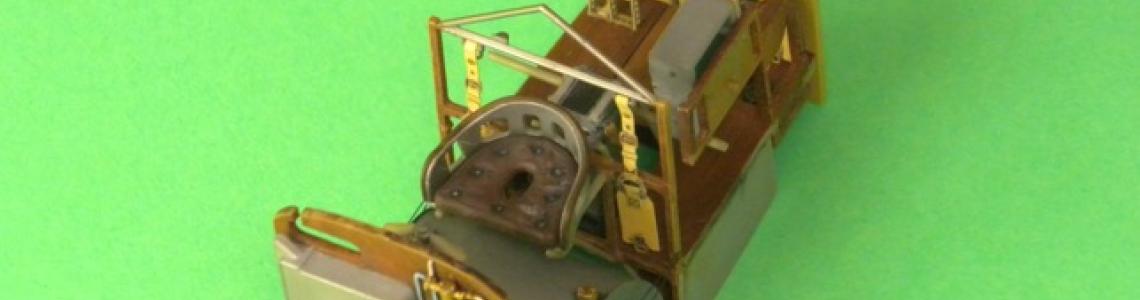

After everything had been painted and detailed, cockpit components were first completed as sub-assemblies (see photos below). Doing that involved adding photo etched safety belts to the pilot’s seat frame and to the back wall beside the folded observer’s seat, bending and attaching photo etched straps to the floorboards, and placing decals on the instrument face and fuel tank gauge (with a dollop of Future applied to simulate the glass cover). It was necessary to add the folded photo etched straps (P2 & P5) from the underside through the slots in the floorboard (part A27) before attaching the floorboard to the cockpit floor. If I had not been following the assembly sequence, I might not have recognized that.

The various cockpit components were then assembled into a single unit (tub), and I found if I followed the recommended assembly sequence everything went together without a hitch (remembering, of course, that that attachment points of all parts in a WNW kit must be clear of paint). It was frequently helpful to place the cockpit tub into one of the fuselage halves to verify that the frames and parts aligned with their respective slots or tabs on the sidewall. Also, it was particularly important to place the hand air pump correctly. Operating it was the responsibility of the guy in the back seat…so it was important to position it as indicated in the instructions so it would be accessible to him.

Because of the Hannover’s plywood construction, the aircraft did not have any structural rigging inside the cockpit. But, the instructions do indicate the location of a few cables that will need to be added using stretched sprue, wire, or monofilament (scale diameters are called out in the instructions). The wireless radio and associated details were then painted and fitted. When dry, the parts were decaled and assembled with no difficulty...with one exception – the small decals for knobs and dials on the radio are extremely tiny and proved to be a challenge to move from the backing sheet to the very small surfaces they were to be applied to. The completed radio is a beautifully detailed addition to the cockpit…so, adding decals to it is not something to rush. I wrapped a piece of thin brass wire around the spool to simulate the antenna wire and threaded it into the fitting in the floorboard. The large FK camera is indicated as an option, but it seemed to me that not including it would leave a conspicuous void in the rear cockpit, so I detailed it with carrying straps, assembled it, painted it, decaled it, and placed it. The engine bearers were painted, oil washed, and added to the forward side of the firewall, or instrument board if you will, again checking alignment to be sure they would fit into their respective grooves in each fuselage half.

I found it helpful to refer to illustrations of the completed cockpit on page 7 frequently during the final assembly to confirm the relationship of the various parts and verify that everything was painted correctly. However, at this point I did find it necessary to make a few color corrections to some of the parts I had pre-painted (if required to complain about anything, it would be that the highly detailed instructions actually provided necessary painting information for some parts that should be painted before assembly a page or two after illustrating how to assemble them). However, when finished, the Hannover’s OOB cockpit is amazingly well detailed…and worth every hour it took to complete it.

The next step in the instruction sequence was the assembly and installation of the pilot’s LMG 08/15 Spandau machine gun. Wingnut Wings provides two options: a basic plastic one and a more detailed version that involves assembling plastic and photo etched parts. The later is not a difficult task to accomplish. It requires carefully rolling the photo etched gun jacket around the forming cylinder provided, painting the parts (mostly black and gun metal), and assembling everything with superglue. Because of the perforated jacket, it is necessary to pre-paint it inside and out with gunmetal, scrape the mating edges, place it, and then carefully hold it and the faceplate with tweezers until the superglue sets up. Three hands might have come in handy at that point, but I managed to get it together. When completed, the finished machine gun looks as good as any aftermarket product.

The gun was test-fitted along with the support bracket and the empty belt chute, but set aside because I chose not to attach them permanently at this point to avoid damaging anything as the assembly continued.

Assembling the engine was the next task, and it was a kit in itself…but a delightful one at that. First, all parts must be painted per the color callouts, oil washed, and highlighted. I did much of it while parts were still on the sprues. The engine’s detail, much like that of the cockpit, is nothing short of impressive. There are optional parts for the cylinders…one with the push rods molded with the cylinders and one that permits the modeler to add them with separate metals rods for a more realistic-looking engine. I chose to add wire push rods and further detail the engine with ignition wires attached to the spark plugs, the spark plug tubes, and magnetos (24 little pieces of wire in all). I used fine brass wire stripped from a multi-strand wire power cord. Unfortunately, attaching all of the fuselage’s engine panels will obscure some of these details, but the multi-part ARGUS As.III engine just begs to have them added (and may convince me to leave off one of the engine panels). When completed, painted, and decaled (yes, there are two decals for the engine sump), the engine can be placed on the engine bearers either before the fuselage sidewalls are permanently closed up, or after they are cemented together. The fit is that good.

The assembled cockpit tub was placed between the fuselage sides and I found closing up the fuselage halves to be a straightforward non-event if the cockpit tub was first firmly seated into one fuselage half. It seemed to click into position when lined up correctly. Everything fit perfectly when the fuselage sides were placed together at the tail first and progressively, and gently, brought together moving forward to the nose...making certain the cockpit tub had remained in the correct position. I used liquid cement along the mating surfaces, squeezing out a little bead wherever possible. After everything had dried sufficiently, a little work was needed around the cockpit openings to smooth out the join, but most of it was done with a sanding stick. I did brush a little Mr. Surfacer along the seam and buffed it out, to be sure.

Assembling the tailplane comes next and, much like the cockpit, it is necessary to decal the parts first. The Cartograf decals were applied per Wingnut Wings’ recommendations. They were floated off the backing after immersing them for 20-30 seconds in warm water, and slid into position on a wet surface. Excess water was blotted with a Q-tip and the decals were then pressed flat. A setting solution was not required but I did brush a little Gunze Mr. Mark Softer around the edges to be sure the bond was complete. By following Wingnut Wings’ recommended application steps, I experienced no problem with the decals bubbling or wrinkling. However, I did learn the hard way that they apparently do not bond as well as I had expected…because, after finishing the tailplanes, I decided to keep rolling along and proceeded to decal the wheel hubs. After applying the lozenge decals according to the recommended practice and allowing them to dry, I decided to mask them to touch up the details in the hub centers. I used Tamiya tape and thought I had reduced the tack adequately by first pressing the tape to my forehead. But, after touching up the hubs, when I tried to lift the tape, the decals came off the hubs along with the tape. After that, there was no way to get them to release from the tape. I gave up and ordered a replacement decal sheet from WNW…and waited patiently for the NZ Postal Service and USPS to deliver my package (three weeks later). So, my advice to anyone planning to mask over any of the Cartograf decals that come in the WNW kits is to do it with Parafilm and Post-it Notes…or, risk the decals pulling off with any tape that is usedm and either attempt to repair them or order replacements from Wingnut Wings.

At this point in the build, the modeler must decide which of the five aircraft options will be built because each one requires different painting and/or markings as well as different styles of tailplane bracing. So, I decided on Option B, CL.II 9339/17, ‘Red 5’, FA 7…and, since the tailplanes had to be painted and decaled at this point, I finished decaling the rear of the fuselage and painted the fuselage in the soft edged mottle shown in the side and top profiles on page 21, using the recommended Tamiya paint mix. The leather padding around the cockpit opening was hand-brushed with Vallejo acrylics, the gun ring was painted gray and attached, and the instruments were placed on the cowling ahead of the pilot’s cockpit. Since all the tail fin decals looked good, I decided to decal each of the wing sections as well. All was going well, but as I was rolling along I discovered something that brought me to a temporary halt. There didn’t seem to be enough decals to do the center section of the top wing. An exchange of emails with Wingnut Wings confirmed that none were supplied and described what I would have to do before proceeding. I’ll explain what that was in Part 3.

As noted in part 1, this is a very, very nice kit, a pleasure to build, and without a doubt will be highly recommended (with maybe one caveat). My thanks to Wingnut Wings for providing this kit and IPMS/USA for assigning it to me. I appreciate the opportunity to build and review it.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews