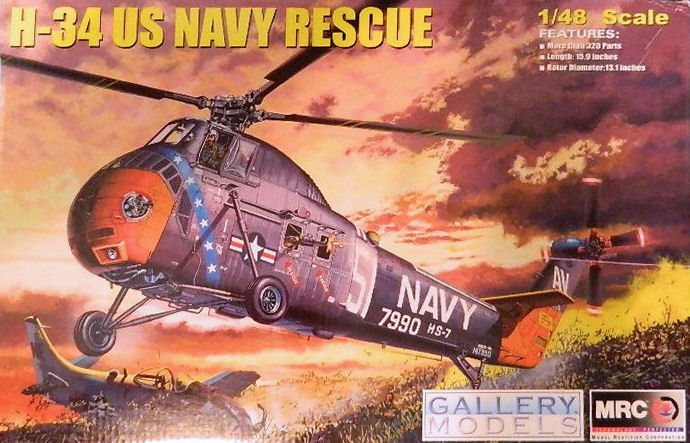

H-34 US Navy Rescue

The first question on every rotorhead’s mind: Is this kit worth the time and money? The answer is assuredly “YES!” Making comparison to the previously released H-34 kit from Revell (which, BTW, was originally released in 1988), Gallery is far and above a better option. Shape is spot-on; the rotor head on the Gallery kit (not to mention the rotor blades) is dimensionally far and above that of the vintage Revell item. (Their rotor head and blades were approximately ¼ smaller than they should have been). There are many parts not used in this build, which indicate follow-on efforts; I don’t have the Marine version, but the parts include armor plating and weapons appropriate for other aircraft, so we’ll see how this goes.

Construction begins with cockpit assembly. This includes seat harnesses (which are fictional by my references, because I can’t find a central chest buckle on any pix of the H-34; and my forays into museum aircraft including “Humphrey” at the Yeovelton RN museum do not show a central chest buckle). Lap belts and shoulder harnesses only!

The central between-the-seats console has a place for the engine mixture controls, but they are not included in the kit. The seats show the proper upward-folding lower section (you can literally enter the cockpit from the lower cabin by raising the seat pan), along with a cushion. There is a bit of photo etch (PE) used for protectors for the control column pushrods; you have to bend them to fit. The tail rotor pedals are attached to the back of the instrument panel (decal on plastic), which has PE brake pedals added to the (correct) right side. When complete, the cockpit looks very realistic. Except for one thing: WHERE are the collective (pitch) controls? There are not in the kit, nor are they in the instructions. You cannot fly a heli without pitch control (makes you go up and down), and they should be on the left side of both seats. A major omission... As this was an OOB build for review, I did not scratchbuild two to put on the left side of the seats, but this was a big one for a kit of this size.

Next comes the engine bay; all parts fit together nicely, but be prepared because you have to install not only the oil transfer lines between the cylinder heads, but also install the upper support brackets between each individual cylinder. Very well done; included in the box are the upper side-discharge three-exhaust stacks (central upper port cowl opening), or you will have the option of installing the central collector ring with a single stack (lower cowl port). Check your references, as the kit does not include markings for the second single-stack exhaust and port cowling. This is a major diorama-plus item. The rotor clutch and cooling fan are also provided.

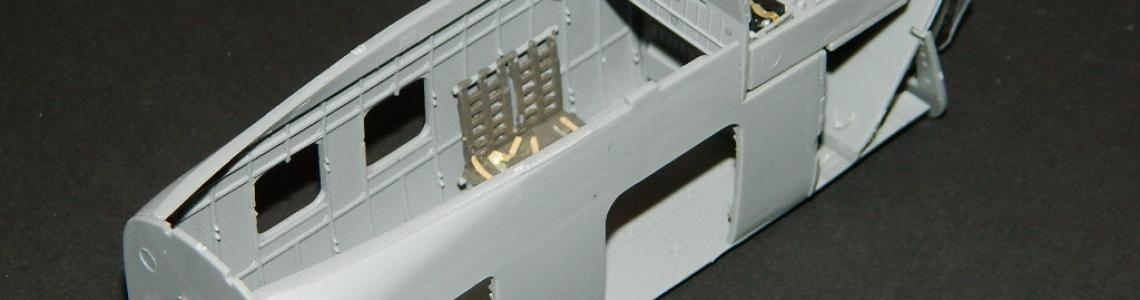

Construction continues with the passenger/cargo cabin. You can fill the area with seats, and PE harnesses are provided for them. The sidewall, fore and aft, and upper cabin walls are all there. This is also the step where you build up the main rotor transmission and oil cooler deck, which goes on the upper cabin area.

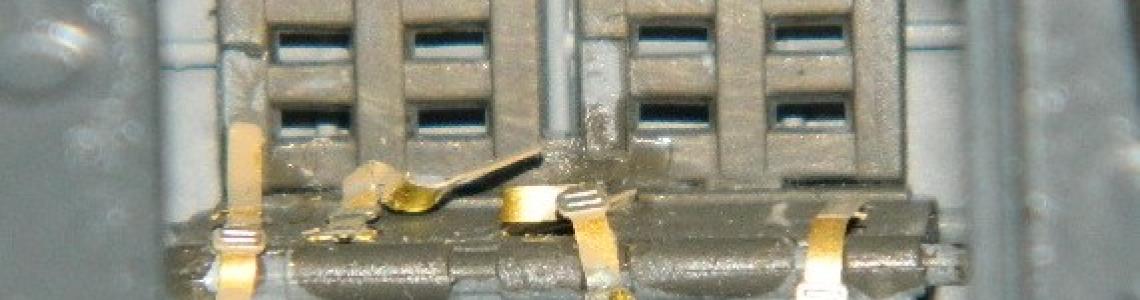

Now the fun begins. Included in the kit are some very well-done screens for the various areas requiring them. A major point for any H-19 or H-34 build, the sequence involves using PE for most of the areas. In the case of the upper nose (PE# 37, 45), the mounting is solid – i.e., you can’t see through like you should. The side (PE #43) parts are better as flat see-through areas, as this is the area where the rotor clutch can be seen. Recommendation: Anneal the brass screens before installation (very carefully, or you will burn them up).

I did two things here that I should not have done. First, DON’T primer the brass, as it will pop-off when flexed, leaving superglue residue to clean up and try again. Leave it as it is. Second, I will cut out the upper areas in the future after using them to shape the brass screens, because they really should be see-through. This makes this kit an experienced-builder option.

Next up is assembly of the fuselage; bring everything together, if you will. I had a bit of difficulty, and I don’t know if it is the kit or me, but I had to use a touch of filler on the upper forward nose area. In the end, it all looks very much like the real thing.

Lower fuselage next; a screen is provided for the lower under-engine air intake area, but that’s an option, not a requirement. More PE screens! And it all fits together well…no more filler (Yay!).

Next step is the canopy. It is a very clear, one-piece item, and the B-46 (overhead console) extends into a clear window area on the upper eyebrow assembly; be advised so you can either paint the window or fill in the back of the console. The exhaust glare shield (part K35) goes on the port side, as does the air vent on the aft portion of the cabin. The two horn-shaped additions on either side of the upper fuselage with lights were designed to prevent glare from the lights on the canopy. Also included is the hoist assembly; this goes together easily.

One complaint here: The crew access side doors are intended to be installed closed. Another major miss here is the rails which these doors slide back on; they are not in the kit, nor on the instructions.

Landing gear time! This kit has the later A-frame, verses the two-strut U-frame; compressed air bottles are included, as are floatation bags which can be attached. I used the bottles but not the bags, as it appears the active Navy birds, from my references, rarely carried them. The cabin door is also glued on at this point, as is the tail wheel assembly.

Early in the build, you have the option of folding the tail; step 14/15 show this, and you need to make a determination now as to whether you are going to do this or not. Parts are included for both, with excellent shaft drive engagement gears on the facings. The tail rotor is very well detailed, with almost impossibly small pitch links in PE to install. Make sure you cement the rotor blades to rotate in the direction as shown on the instructions; I installed the parts backwards and had to regroup. (That means cut them off and glue the other way). Missing is the prominent handle on the upper leading edge of the fin; clear beacon and tail lights are, however, included.

Last up is the main rotor head and rotors. The blades have droop molded in; no more broken blades trying to incorporate it! I drilled out the shaft area and installed a longer, sturdy steel shaft in its place, so it could go all the way through the transmission and not allow the rotor head assembly to droop to either side. There is no provision for folding the blades in the stowed position. Again, PE is used for the upper cooling vent area, but like the upper nose, only a recessed area with plastic fill is provided versus an open area. Another opportunity for modeling skill in the future.

Markings are provided for an overall gray-with-orange U.S. Naval aircraft from HS-7 from USS Randolph in July 1961, or an Italian aircraft from the same time period. The decals worked and did not silver over the gloss pain, but were rather thick and glossy themselves and required about three gloss coats to blend in. The Squadron In Action book has a picture of #41, and it shows the Doppler antenna which is missing from the kit.

I really looked forward to this kit, and the little nits aside, I am pleased. I’ll be buying more (my father flew these with the VNAF from Danang in 1966-67, gotta do them) and intend to see what I can do with the basic kit. My sincere thanks go to our great supporters at MRC for providing IPMS/USA this new, fantastic model of the H-34! And also thanks to Gallery for taking the time to develop this kit…and IPMS/USA for letting me have first crack at this one!

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews