GAZ-69A Personnel Truck

History and Performance

The GAZ-69A was a four-wheel drive light truck designed and built for the Russian military in the late 1940’s. Supposedly, the design was based on the American Jeep provided to the Russians during the war as part of the Lend Lease program. The four-door GAZ-69A was a field car for officers or up to eight troops. The car weighed in at 1,525 kg, with a carrying capacity of 500 kg. The car was powered by a 55 bhp, 2.12 liter diesel engine. The car was exported to several nations in Africa, the Middle East, and Asia.

Kit Review

Instructions – The instructions are provided in a 20-page magazine, printed on high quality, glossy paper. The instructions include colors and recommended paints by manufacturer (Mr. Hobby, Hobby Color, Humbrol and Tamiya), a sprue layout, and four pages of painting guides for no less than ten vehicles. Based on the content of the instructions and the complexity of the many construction steps, this kit is recommended for experienced modelers. Overall, the instructions are probably the best I have seen for such a complicated build.

Sprues and packaging – The model arrived in a very sturdy cardboard box. There are ten tan sprues, one sprue of clear parts, the fold-down top, and plastic tires, all bagged separately.

Clear Parts – The clear parts included the windshield, side windows with curtains, and the head light and spotlight lenses.

Photo Etch – The small fret of photo etch includes the fan blades and miscellaneous brackets.

Decals/Markings – The decal sheet includes license plates for all the featured vehicles, along with national insignia and stenciling.

Figures – There are no figures included in the kit.

Construction

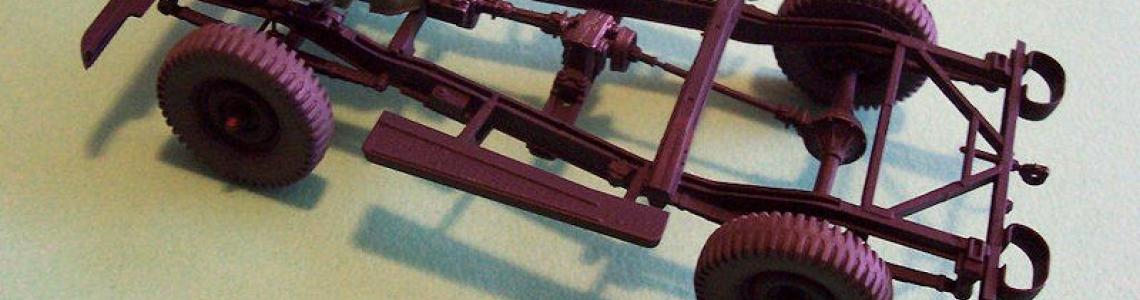

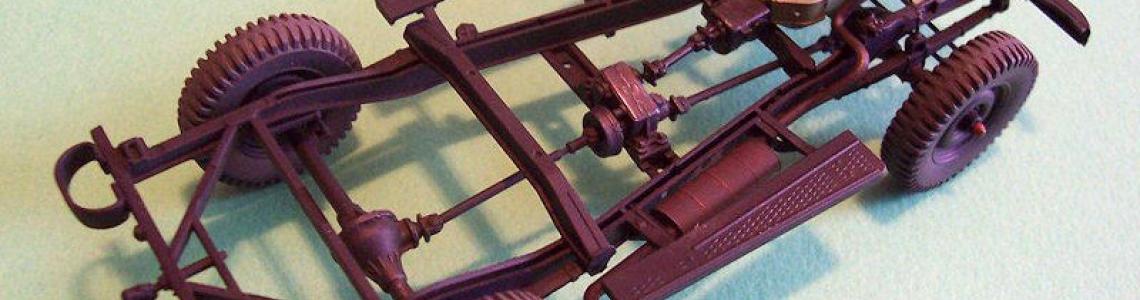

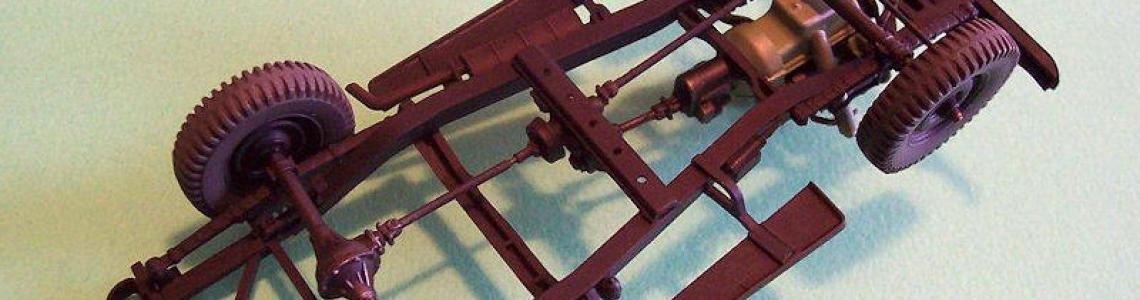

Frame and Suspension System – There are four steps to the frame and suspension system construction, with several very small plastic and photo etch parts involved in each step. The builder will need to eview each step thoroughly to avoid any problems with placement and alignment of the parts. I had some difficulty in fitting the leaf spring, part F9, to the frame. There were just no positive locators for the leaf spring. When I fitted the opposite leaf spring in place, I found the placement went a bit easier.

Steps 3 and 4 address the assembly and fitting of the front and rear axles and drive shafts to the chassis. Care is required when fitting the many small parts to the front axle, as misalignment is a real possibility that may not be discovered until the wheels are fitted in place. This assembly will later prove to be a weak point in the model: the many small parts in these two assemblies do not lend themselves for a strong or rigid axle, and later handling when fitting the body to the frame runs the risk of breaking off the wheels.

Once completed, I found that the left rear wheel was just barely above the work surface (almost unnoticeable).

Wheels and Tires – The kit has two sets of wheels and tires included. The primary difference is the tread patterns. The instructions do not make any reference as to which specific vehicle the particular tires are to be used, but rather the painting guide does show the Polish Army vehicles uses the “knobbier” tread pattern tires. That mystery is solved.

Engine/Radiator/Transmission Construction – There are four steps to the engine/radiator/transmission construction before this sub-assembly may be fitted to the frame. Again, careful study of the instructions is important to verify orientation of the small parts. I deferred installation of the radiator and two hoses until the engine was in place on the frame.

Interior – The interior construction begins with the underside of the body pan and, in the following step, the body pan is flipped over and the seats and various brake and transmission shift levers are installed. Each seat is comprised of a simulated tubular frame and cushions.

Body Construction – The four crew access doors are molded separately and may be posed open once the mounting hinges have been removed. The tailgate may also be posed open with the rear compartment revealing the spare tire storage. The door handles, all eight of them, are molded separately and are quite small and quite challenging to remove from the sprue and clean up. I managed to lose just one during the build.

The windshield frame part K37 fits onto the front cowl and is a very difficult fit. There are no real good mating surfaces to fit the part together, but, with patience and solvent, the two parts were finally brought together. When I test-fitted these parts to the body sides, it appeared the top of the windshield frame is too far forward for the fit to the ragtop.

The rear window for the ragtop would not fit. I needed to bevel the top and bottom edges before the window would fit, and the fit was still tight. Also, in step 13, part K34 is glued in place behind the rear seat. This is the fuel filler tube and should be installed once the sides have been fixed in place.

I fixed the sides to the bottom pan and installed the tailgate in an open position. Fitting the assembled body to the chassis was problematic at best. It was a very tight fit, but with some effort everything finally fitted in place. I needed to work my way around the perimeter of the body to make certain that everything was properly aligned (close, but not perfect).

Armament – The 12.7mm DShK heavy machinegun is a model unto itself. Plastic and PE parts comprise the assembly. A tripod stand is also included for mounting this heavyweight in the back seat of the vehicle. In the event the gun is mounted in the vehicle, the fold-down top may not be used.

Painting and Finishing

The complexity of the construction led me to decide early that painting all the subassemblies separately would be the way to proceed with this portion of the build. This same philosophy was carried to the body of the vehicle. I decided on the Syrian Army color scheme, only because it appeared to be the most “colorful”.

Decals

The subject that I decided to build uses only one decal, and that is in Arabic script for the front bumper.

Conclusion

As noted above, this model is for the experienced and patient builder. Many of the parts have tabs that fit into recesses on the opposite part, but several were merely butt joints, making placement a bit more challenging. There is a lingering concern about possible misalignment (however slight) for some of the sub-assemblies that might not be discovered until well into the build. The many small parts require careful removal from the sprue to avoid breakage. Cleanup of the small parts is challenging.

Review the instructions thoroughly and look ahead to the next steps to avoid possible problems with the fit of parts and conflicts with succeeding steps. The many small parts make for a longer build time. The combination of small plastic parts and the delicate photo etch often makes for a fragile assembly that may not hold up under the stress of fitting subassemblies together.

I wish to thank Dragon USA and IPMS/USA for the opportunity to build and review this kit. Although it was a complicated build, seasoned with some intense effort, I enjoyed this model. The painting offers a variety of national topics, all but one multi-colored. This model should prove popular with those wanting to add something unusual to their collection. Recommended for the experienced builder.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews