FT-17 French Light Tank

Background

The French Renault FT-17 can claim the distinction of setting the standard for tank design for the entire Twentieth Century. By the end of 1915, Jean Baptiste Estienne, General of Artillery and a specialist in military engineering, realized that artillery could be mounted on tracked armored vehicles. This vision led him to create the French tank arm. He is considered by many in France to be the Père des Chars (Father of the Tank). Some early companies approached by Estienne produced medium size tanks – the Schneider and the Saint Chamond. Estienne believed, however, that a light tank was needed, and approached Louis Renault in July, 1916, who then developed the FT-17. Innovative in its design, the FT-17 featured the first rotating turret, along with a rear engine compartment and front driver compartment, and only weighed around 7 tons. Early FT-17’s were armed with an 8mm Hotchkiss machine gun, and later designs carried the 37mm Puteaux canon.

The French army received its FT-17’s in March, 1918, with the first unit being the 501 Regiment de Chars de Combat. The FT-17 saw action on May 31, 1918, during the battle for the Forest of Retz, in which the light, two-man tank performed quite well. By the Armistice, some 3000 FT-17’s had been built. Following the Great War, the FT-17 continued to have success, being exported to Belgium, Holland, Poland, Czechoslovakia, Russia, Brazil, Spain, Finland, China, Japan, Canada, and the United States, where it was known as the 6 Ton Tank. The FT-17 saw action in World War II, as the French Army still had ten battalions equipped with Renault FT-17s in September, 1939.

The Kit

The Renault FT-17 by Meng Models is attractively boxed with 10 sprues in 8 bags, totaling some 335 plastic parts, along with one PE fret of 9 parts, a bag of 68 individual tracks (in black plastic), and 8 metal parts (2 large springs, 2 small springs, 2 axis rods, and 2 bars). The amount of parts is due, obviously, to the fact that Meng’s FT-17 provides for the building of a complete interior. This has indeed been rare in World War One armor in any scale. The Meng FT-17 has a beautifully detailed engine for the rear compartment, a well-designed driver’s compartment, and a detailed center compartment inside and below the turret. Displaying all the main hatches in an opened position will reveal most of this detail.

Inspection of the plastic parts shows the quality of the Meng moldings, which are crisp and clean with virtually no flashing visible. Some of the parts are very delicate (F4, G27, G20, B18) and care needs to be taken in removing them from the sprue, as well as handling and cleaning. Another nice feature that Meng provides is that both the gun barrel for the 37mm canon and the exhaust pipe of the muffler are already drilled out for you.

The instruction booklet is well laid out, with four languages provided in the step-by-step instructions – English, Chinese, Japanese, and Russian. Four profiles of the FT-17 are also provided with matching decals. The four tanks you can build are a French FT-17 from the 4th Platoon, 1st Company, 29th Tank Battalion from May 1940; a French FT-17 from the 1st Company, 2nd Battalion, Le Tigre Regiment from late 1918; a Finnish FT-17 from the 2nd Tank Company from February 1940; and a captured FT-17 serving the German Luftwaffe in France during the summer of 1944. I decided to build the only WWI profile of the four.

The paint suggestions are based on Vallejo Air (71000 series), and a total of 21 colors are referenced. If there is a slight weakness in the Meng instructions, it is that not all the parts are marked with the suggested Vallejo paint number.

Construction

Building began with the engine compartment sub-assemblies. The transmission (14 parts), the engine (17 parts), and the radiator (13 parts) all fit perfectly with no problems. Once again, some care needed to be taken with some of the rods and piping parts which are quite detailed and delicate. The engine depicted is the Renault Buda HU 4-cylinder engine. This can be further detailed with spark plugs and wires, for instance, which would be visible with the engine hatches open. However, because I want to keep this a purely Out Of Box build, I decided not to detail the engine assembly any further.

The power system was then added to the flooring. This combines with the driver’s controls affixed to the under-flooring and driver’s seat and leather back strap on the upper-floor. The transmission section and the driver’s compartment were completed with the control lever assembly.

The next task was to begin preparing the interior hull halves. The left interior hull has the 37mm rounds stored in a rack that affixes to the hull wall. The right interior hull has a few auxiliary parts. Particular attention needs to be given to which profile you are building, as the instructions clearly show what parts are to be used in the interior, depending on the tank you are building (marked profile A, B, C, or D).

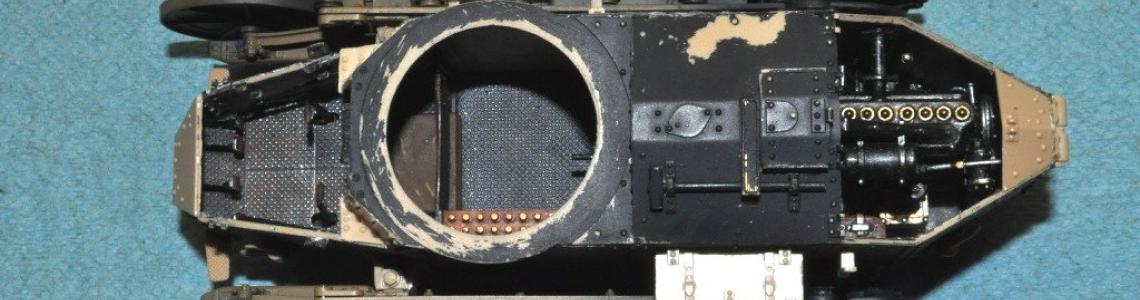

Moving along, the next steps included the assembly of the top armor plate which holds the turret, and the adjoining front plate hull assembly. One of the only difficulties I experienced was the placement of the small triangular deck panels and the adjoining side front panels that are on either side of the front driver’s window hatch (parts A14, A17 and A16, A15). I did not install the center window hatch (B7) at this time, but did dry fit it as a guide to installing the adjoining front armor plates. Because I was going to position all the hatches in their open position, I decided not to install any of the hatches until later in the build process.

Setting the tank body aside, assembly of the wheels and running gear sections was next. As to be expected, there were a lot of parts, but no real problems were encountered. There was need for quite a bit of tedious cleanup of all the small wheels where they were cut from the sprue, and the attachment nubs needed to be snipped, scraped, and sanded off. All the wheels were assembled without glue, except for some unifying rods to hold the assemblies together, and the precision of the fit here will be appreciated. The detail is impressive and not much is left out. For instance, double leaf springs are provided for both assemblies, placed inside the wheel housings, and will be completely enclosed and never seen. But you will know they are there! The metal springs, once installed, provide for real suspension, as well as the spring and rod shock absorber unit installed on the side of the hull. Once complete, the running gear assemblies were affixed to both sides of the hull.

The un-ditching tail assembly has two different configurations depending on the tank profile you have chosen, and neither will present any difficulty. I chose to assemble this tail section but not install it until after painting the hull.

The individual tank tracks snapped together easily and effectively. There are 32 tracks called for to complete each track length for each side. I assembled these two separated lengths and painted them off the tank. Later, it was relatively easy to wrap them around the wheel assembly and snap the final joint together. This was made easier by the fact that the spring suspension provided some give, although the 32 tracks are enough that the fit is more on the loose side rather than a tight fit.

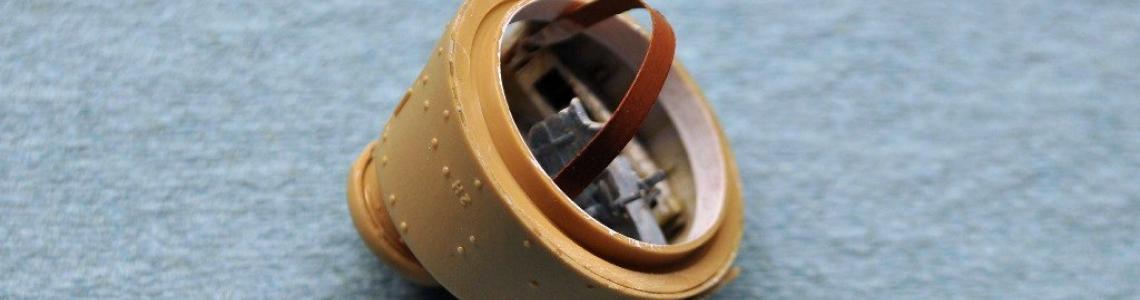

All that was left was the turret and gun assembly. Once again, pay attention to your profile, as two of the tanks use the 37mm canon, one uses the 8mm Hotchkiss machine gun, and the fourth has a Reibel MAC Mle.31 machine gun on the captured German version. All three gun armaments are provided by Meng, along with ammo and racks and containers. The weapon was then attached to the inside of the turret, along with the accompanying bracket (again, pay attention to your profile). The gunner’s seat is a PE part that replicates a leather swing seat suspended inside the turret. This belt needs to be painted on both sides, as it is possible to see the backside of the upper portion once it is glued in place to the inside of the turret wall. The outside of the turret has a four-part top hatch assembly, which will be the only hatch that is mounted in the closed position. The entire turret assembly was then set down into the hull, using the joining ring (part J12).

Painting began with a primer coat of Vallejo Air Black. I then sprayed the interior hull with Green Brown (71030), and then over-sprayed and brushed that with White (71001), except for the engine compartment, which I left the Green Brown. The floor was painted with a coat of gun metal and drybrushed with aluminum. Some reference photos show this metal floor to have a green paint covering, but I left mine metal. The interior was then given a wash of Burnt Umber and Black. The floor was also brushed with some Doc O’Brien powders to provide some dirt and grime in the corners and around the foot pedals.

My WWI profile FT-17 has a three-color camouflage with a black dividing line painted between the colors. This was all field-applied and should show a less than precise application. I taped my hatches closed from the inside and laid them in position on the tank (I did not glue them into place until later, but wanted to make sure they matched the camo scheme). I began with a base coat of Light Brown (71027). After that dried, I masked my next section with silly putty strips which are easily rolled out and applied to conform to the complex shapes of the hull, front glacis armor, turret, and wheel assemblies. I sprayed Camo Light Green next (71006) and, after drying and masking again, sprayed the third color, Tank Brown (71041). Once dry, Vallejo Air black was used with a small brush to paint the dividing lines. To blend in the overall camo scheme, I sprayed a light coat of Green Brown (71030) over the entire model. For my version, the tail section has a tarp covering, which I painted in English Uniform (70921). The muffler was also painted in various shades of rusted metal and glued in place at the right side of the hull.

The French WWI version of my tank was from the Le Tigre regiment, so the only decals I needed to apply were the Ace of Hearts and Le Tigre emblem. These were positioned on each side of the rear hull. I applied some Future by brush to this area and let it dry for the rest of the day. The two decals went on easily and proved to be very sturdy, especially when I needed to pull one up and reposition it to make sure it was straight. A flat coat was then applied.

Chipping effects came next. This was accomplished mostly with a green abrasive pad dabbed in Burnt Umber and touched randomly to the high points and edges of the hull. A graphite pencil was used to accent certain areas of wear around bolt heads and high traffic edges. I kept rusting effects to a minimum (as I feel that most armor models lately have been over-rusted).

The tracks were painted in black (71057) and washed with Rust (71080) and Fire Red (71084). Once dry, another wash of Mahogany Sand was applied, especially to the joints. Once assembled, a graphite pencil was rubbed on the track edges to provide further weathering and wear.

Some final details included gluing of the hatches in the opened positions. The driver’s window hatch with its sliding bracket rod was glued in place, and then the main front hatches were glued in place wide open, showing the detail of the driver’s compartment. The rear turret hatches were also glued open, and with a pen light you can see all the nice detail of the inner turret and gun compartment, along with the ammo rack and the gunner’s leather seat strap. Finally, the engine hatches were glued in place. There are three hatches here, two side hatches and one center hatch. These all open upward and towards the turret. In the open position they look rather awkward, but it is worth the risk so you can see all the detail of the nicely designed engine and radiator grille assembly. The interior walls of the engine compartment as well as the underside of these engine hatches were weathered to show spotty oil and exhaust stains and grime.

To finish off the model, I applied some washes (black and burnt umber) at various places on the hull and track assembly, and in all the areas where detail could be enhanced. I applied some streaking effects at various places around the hull with Doc O’Brien’s pigment powders.

For display, I decided to place the FT-17 on a simple dirt and grass area base. Because all the hatches are open and it is obvious that the tank is standing still and receiving some maintenance (and also to give the tank some scale reference), I added a tool box, a small can, and an oil drum to the base. Meng provides for the separate build of the Hotchkiss M1914 machine gun on a mount along with ammo belt and containers. This would also be good to use alongside the tank for scale reference (assuming you did not build profile C, which houses the Hotchkiss inside the turret).

The Meng FT-17 took one month to assemble and finish and it was a great kit to build, with virtually no problems encountered. The parts are detailed, strong and crisply molded, the fit is precise, and the instructions are clearly laid out. I would recommend this kit to anyone, especially to those who want to up their game into more complex armor model building. Follow the instructions and you will be rewarded with a great model of an iconic tank.

I would like to thank Meng Models for the kit, and also IPMS/USA for the opportunity to build and review this kit.

References

- Tanks, Michael Green, Zenith Press, Minneapolis, MN, 2008.

- Renault F.T., Armour In Profile, Number 13. Pierre Touzin and Christian Gurtner, Profile Publications Ltd., Surrey, England, 1967.

- FT-17 / M1917 WWI Tanks Walk Around. David Doyle. Squadron/Signal Publications, Carrollton, TX, 2011.

- Armoured Ancestor, Jon Feenstra, Military in Scale, June 2000, pp.29-31.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews