Focke-Wulf Ta-152C1/R14

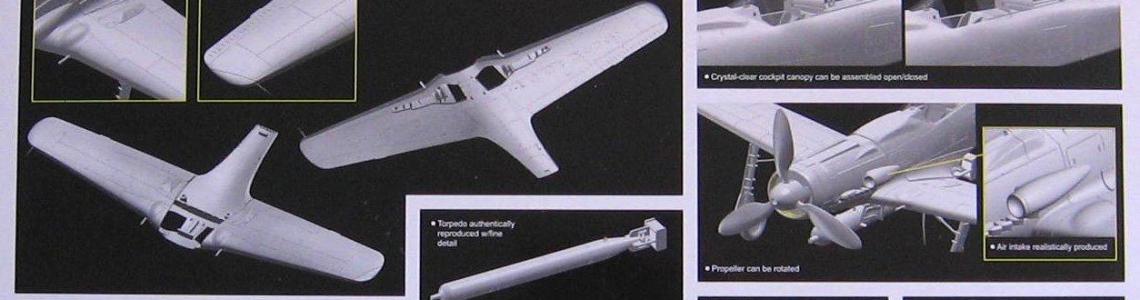

This kit uses the good old Trimaster molds with some new plastic providing the correct wings, the torpedo and a few other parts necessary to make a Ta-152C. There are three small photo etch frets that contain various detail parts. Two styles of canopy are also provided. There are separate parts provided for open or closed cowl flaps. The decals, clear parts and photo etch parts are all attached to a printed piece of heavy paper to keep them from jostling around in the box and getting damaged. The kit is molded in light grey styrene, with the older parts in a shinier plastic than the new parts. The older parts are starting to show some signs of mold wear, but they are still very nice. The older parts were also more brittle than the newer parts. I actually took a chip out of one of the side consoles in the process of nipping it from the sprue. From that point on, I used a razor saw to remove the more delicate parts. The instructions are in Dragon’s usual style, with color callouts from the Gunze range of paints. There are quite a few unused parts to help stock your spares box.

A new nose section is provided, and surgery is required to fit it. I tried to cut just slightly forward of the panel lines indicated in the instructions, just to be on the safe side. The new nose section is made up of three parts; left, right and upper cowling. When the new parts were dry-fitted to the fuselage, the upper cowling sat about 1mm too low, and it was a little too narrow to match up to the assembled fuselage. I can’t necessarily blame the kit for that, as some slight warpage of the cowling halves could have been the culprit. I glued a chunk of sprue inside the rear portion of the cowling in order to spread it out enough to make it fit properly, and added a thin strip of sheet styrene to bring the upper cowling up to the right level.

The cockpit interior is nicely detailed, with separate side consoles, rudder pedals, and photo etch seat belts. There are a couple of ejector pin marks on the cockpit floor and the inside of the fuselage that need to be dealt with. The interior was painted in RLM 66, with details picked out in various colors according to references. The seat is supposed to fit on a raised block on the cockpit floor that has two holes in it. Unfortunately, there are no corresponding pins on the bottom of the seat. Placement of the seat is somewhat critical, due to the fact that the photo etch shoulder harness attaches to the upper rear portion of the cockpit. I decided to wait until the fuselage was together before I glued the seat in place so that I could get it in the right position for the shoulder harnesses.

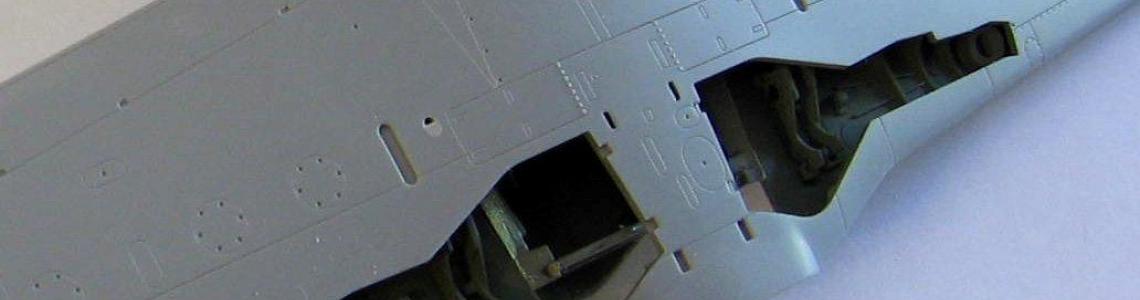

There is a spar that runs across the back of the wells, and detail on the inner surface of the upper wing, which adds detail to the outer portions of the wheel wells. However, there is nothing in the center section of the wheel well. There is one piece of fuselage bracing, but otherwise it is an empty hole. In the original Trimaster offering, there was some detail in this area, including the rear portion of the engine. I had an Engine & Things resin engine that I considered putting in, but since this is a review kit I decided to build it as it comes in the box. If you attach the finished model to a base, it might be difficult to see the lack of detail in the wheel well.

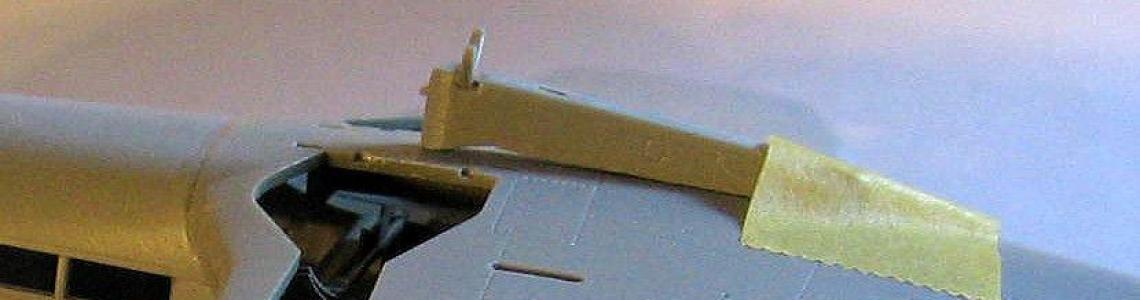

Per the instructions, I drilled out the locating holes for the torpedo mount before attaching the wing to the fuselage, only to discover later on that the holes don’t line up with the pylon used to hold the torpedo. Unfortunately, that wasn’t the worst problem with the pylon. The shape of the mating surface of the pylon is not close to the shape of the underside of the wing, so a lot of sanding and test fitting was required. Since neither of the holes that I had drilled out was in the right place, I had to do some guesswork regarding how far forward to attach the pylon. I happen to have a copy of the Schiffer book on the Ta-152 which contains a line drawing of the C-1/R-14, and I used that along with the box art as a guide for placement. I also had to fill the rearmost hole that I had previously drilled out.

I finally got around to attaching the seat. The kit comes with photo-etch seat belts, which I tried to use. They appear to be of a material harder than brass (steel?), and I wasn’t happy with the shape I was getting when trying to bend the lap belts. Then I lost one of the lap belts and decided to dig out an Eduard color PE set of Luftwaffe seatbelts and use them. They are much easier to work with and are painted far better than anything that I could do.

The wing to fuselage joint was one of the best that I have encountered in recent years. No gaps, no sanding, no filling! I simply ran some Tenax into the joints and that was it. All of the joints are along panel lines, so the only cleanup I had to do was in a couple of areas where I was a little too generous with the Tenax. There are a couple of etched pieces that go on the inboard trailing edges of the wings. I think they must be stiffeners of some kind. The kit wings are molded with a raised section in the area where the etched pieces attach, and the instructions would have you glue the etched pieces onto these raised sections. I felt that it would have looked out of scale, so I shaved off the raised section on the wing and then glued the etched pieces in their place.

There are two different styles of windscreen and canopy provided; one being of the blown variety. I wanted to use the blown canopy, but the windscreen was too narrow to fit over the instrument panel coaming. The other windscreen fit nearly perfectly, so I used the non-blown canopy. After masking, I glued the windscreen in place with Gator Glue and temporarily attached the sliding portion of the canopy with a little white glue. I then sprayed the canopy with RLM66 and primed the model with Mr. Surfacer 1000. Luckily, I only had a few minor touch-ups on my seam work, mostly on the leading edges of the wings. As I was working on them, I noticed that there were a couple of panel lines on the leading edge of the wing that didn’t go all the way around to the other side of the wing. They simply stopped at the mating surfaces. Two of the panel lines came up from the lower surface of the wing and one came down from the upper surface. They were only about ½ an inch apart from each other, so I just scribed a panel line along the leading edge of the wing to make them all come together. It might not be accurate, but in my opinion it looks a lot better than panel lines that go nowhere.

I was finally ready to paint. The instructions call for late war colors of RLM 76, RLM 75 and RLM 83. Like a lot of the late war 190s, this aircraft had a natural metal section across the lower surfaces of the wing. I used Alclad Aluminum for the natural metal portion, then masked it off and sprayed the RLM 76 on the lower surfaces and fuselage sides. I used the new acrylic paint from Italeri for the 76 and 75. Look for a review of these paints elsewhere on the IPMS/USA website. I used Aeromaster RLM 83 enamel for the green. I used Blu-Tak for masking the leading edges of the wings and the camo pattern on the upper surfaces. After touching up a few areas of overspray, I was fairly happy with the paint job. I had left the horizontal tail planes off until after painting, and I attached them now. The fit was a bit sloppy, so I had to eyeball them to make sure they were straight.

I applied a coat of Future in preparation for the decals. There are markings provided for the prototype, and also for a fictitious operational aircraft. I decided to go for the prototype markings. According to Schiffer’s Focke-Wulf Ta 152: The Story of the Luftwaffe’s Late-War, High-Altitude Fighter by Dietmar Harmann, the Ta152 V-7 (Werke No. 110007) was the airframe that was used for the torpedo trials. This is the aircraft that I decided to model. The images on the decal sheet are very close together, so care must be taken when cutting them out. I normally use a pair of fly-tying scissors to cut out decals but, since these were so close together, I used a sharp X-Acto knife. The decals are thin and performed very nicely using Micro Set and Sol, and they were tough enough to withstand my less than gentle handling.

There is no swastika provided on the decal sheet. I have a couple of aftermarket sheets of swastikas produced by Aeromaster and Techmod, so I used them. Looking at the pictures in the Schiffer book, I determined that the swastika was of the solid black variety. Unfortunately, I didn’t look at the picture before I started placing the decals. If I had, I would have noticed that the swastika is on a diamond-shaped patch of RLM83. So I had to mask off the area and drag out the airbrush again to paint two small areas of RLM83. Note to self: Do a little more research on the next project before painting .

I decided that I could not live with the way the supercharger intake looked. The intake is split horizontally and the opening is very shallow. There is a seam running across the opening and I had contemplated trying to cut a piece of screen to cover it. A modeling friend of mine suggested that I just drill it out and paint it black, so I did that and I am happy with the result. Just about the time that I finished with the drilling, it dawned on me that I should have taken a picture of the way it looked before to accompany this review. My apologies for not doing so.

I coated the model with Acryl Clear Flat, which actually leaves a slight sheen. Then it was on to the portion of the build which always seems to me like it takes forever; the attachment of all the fiddly bits. In this particular case, it did take me longer than usual, mainly due to the exhaust. I had decided to leave the exhaust off until I was done painting, and since the exhaust is attached from the inside, I left the upper cowl off to ease installation of the exhaust. There is a new pair of exhausts provided to fit in the new nose section. However, when I went to test fit the exhaust in to the cowl, I discovered that they are too short to cover the slots provided. After some grumbling, I decided to use the original exhaust parts that were designed to fit in the original nose. Unfortunately, the exhaust stubs did not fit around the vertical braces in the new cowling exhaust openings. So I proceeded to cut out those vertical pieces with a razor saw, glue in the exhaust stubs, and call it good.

The wing-mounted guns are mislabeled in the instructions. Use part G22, not part M19. M19 is the upper cowling machine gun. The instructions would have you cut off a portion of part M19 to make it shorter but, since it is glued into a hole in the upper cowling, I simply pushed it a little farther back in the hole. I drilled out the opening of all four gun barrels.

The landing gear fit without too much difficulty. From the front, the inward angle of the gear legs looks good, but from the side I think they should have had more of an angle to them. The support braces of the landing gear did not seem to have a positive location point where they attach to the wings, so I glued one end to the gear leg and I put a couple of drops of Tamiya extra thin cement at the point where the support touched the edge of the gear well. All the other fiddly bits presented no problems and the model was finally finished.

I would definitely recommend this kit to anyone interested in the subject. I am pleased with the finished model and, even though there were some difficulties along the way, it should not present too much of a challenge to the average builder. At first glance, it looks like another long-nose Fw190, but the torpedo slung underneath gives it that little extra visual interest. My sincere thanks to Dragon USA for the opportunity to build this fine kit and to IPMS/USA for the opportunity to review it.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews