FE.2b early Part 4

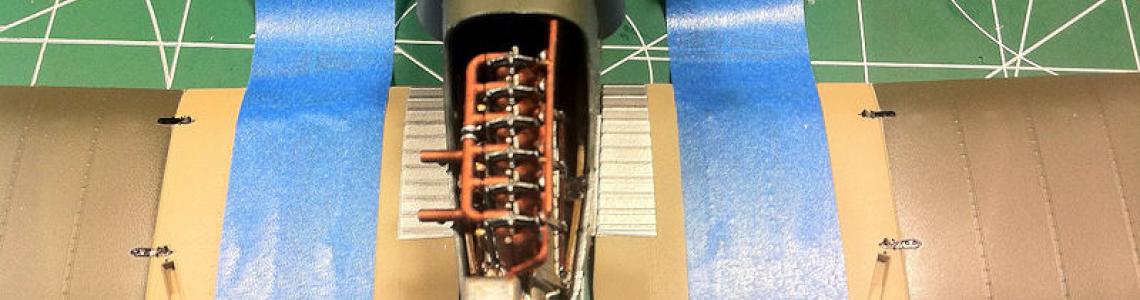

Attaching the wings. The lower wings were first and to ensure everything was in alignment, I cleaned the mating surfaces of paint, did a test fit, and applied the Gunze liquid cement. Getting everything properly lined up, I taped the wings down to the work surface to dry. Don’t do this.

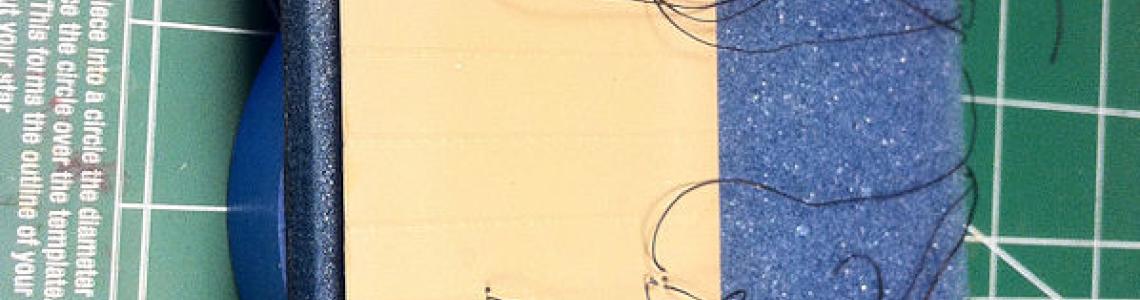

Having painted all of the wing and cabane struts with Tamiya tan acrylic, and after that was dry using the basic Wingnut Wings technique for replicating wood that is found on their website, I applied burnt sienna oil paint with a sponge, then removed a great deal of that with a stiff bristled chisel brush to get in some wood grain effects. These have to dry for at least a couple of days, if not more, depending on your locale’s environmental conditions. I suspect there is a liquid agent that would speed up the drying time of oil paint and I’m going to look into this.

While this was curing, I set about drilling all of the rigging holes a bit deeper and cleaning out any paint in them. I decided to use the larger version of EZ Line with the FE because it’s a big airplane and, stretched a bit, I think it looks in scale…and the fine stuff is a little too fine for this airplane. Matter of opinion, though. And, I like black for rigging. Metal-colored rigging lines don’t look right to my eye. I then donned the Optivisor, cut a gazillion pieces of EZ Line, got my tweezers, and commenced to install the rigging lines into the bottom of the top wing assembly. I used a plastic bottle cap that I had indented a bit with a hot drill bit end to form a small cup for holding a puddle of CA. I secured the plastic cup/lid to the work surface with a blob of Blu-Tack.

The procedure:

- Grab a piece of EZ Line near one end with the tweezers.

- Drag the bitter end through the CA until you get a small blob on the end of the line.

- Carefully plug the EZ Line end into the pre-drilled rigging anchor hole.

- Hold it until it sets (or, with your third hand, apply a bit of accelerator to the spot with a toothpick or other suitable tool). I found that it was a good idea to return to each of these anchored bits of line later and apply a small bit of CA to the line where it enters the hole. Gives a secure anchor and bond.

- I used small blobs of Blu-Tack to secure the gathered strands of EZ Line on top of the wing after I was done attaching them all. Better to keep them out of the way when mounting the top wing to the struts.

The strut hardware and those metal bits on the wing surfaces that will later accept rigging and control ‘wires’ were also picked out in semi-gloss black. Once all of that was done, I fitted the struts into position. Take care that you select the correct struts for the version of aircraft you are doing. There are differences. Everything fit properly and securely. No worries about wandering struts here, they socketed in nicely to their holes and stand pretty much where they are supposed to stand. Feeling quite proud of myself, I brought down the big top wing to line up with the struts.

The wing-to-cabane strut alignment was right on. However, the outboard wing bay struts were not reaching their anchor points in the bottom of the top wing. The farther out to the end of the wings, the further the gap. I had a dihedral problem. That was directly attributable to taping the bottom wing to the work surface while it cured. There obviously needs to be a dihedral on the bottom wing to enable the struts to reach their respective anchor points in the wings.

So, after removing the two lower wings from the nacelle (this is easily accomplished by resorting to a number of colorful incantations I learned while in the Navy), I re-attached the bottom wings with what turned out to be pretty much the proper dihedral. If left to their own devices, the wings tend to assume that orientation by themselves. (The Wingnut Wings designers really do know their stuff.)

So, I went at mounting the top wing again. I secured the cabane struts in their sockets and let that dry for a while. Then I worked my way out to the next set of struts, alternating between port and starboard strut pairs, until I had them all secured and glued. I applied a couple of heavy tubs of sculpting materials to the top of the wing until the glue was set but not concrete, then checked the alignment by standing the model on its wings’ leading edges in the empty box lid. Perfect. Then, keeping everything the same, I put the model back on the nacelle and lower wings and loaded them again with the tubs until they were good and dry.

At this point, I have rigged the cabane struts and am working my way outboard for the rest. I bought a bottle of CA accelerator and another hand at Hobby Lobby, so this might go a little faster. Or not.

Next will come the landing gear. I plan to assemble and paint it, but not to install it until the tail booms are on and rigged.

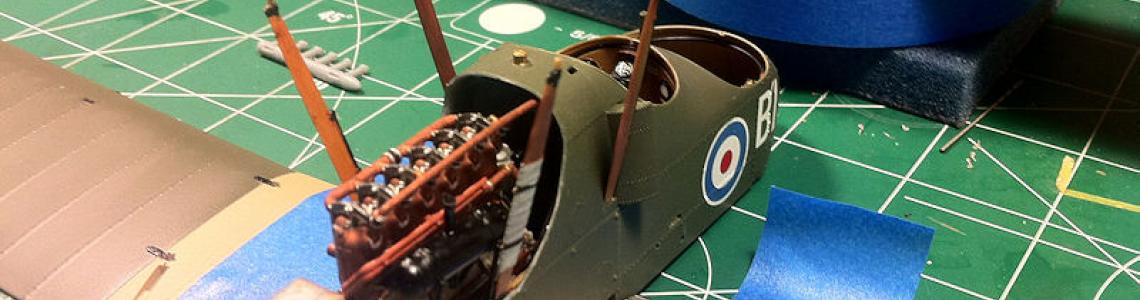

For those who like complex kits that are engineered to be good builds – great detail, not too many fiddly parts, parts that actually fit, and having that “wow!” factor (look at the engine or inside the cockpits on this kit for example) – Wingnut Wings kits should be at the top of your list.

And, for an up-to-date look at the roles of these kinds of aircraft in WWI, the men who flew them and why, I strongly suggest you get a copy of Bloody April: Slaughter in the Skies over Arras, 1917, by Peter Hart. I thought I knew a lot about the WWI air war, but I have only dipped a little below the surface. If you are at all interested in this area, buy this book.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews