F/A-18F Super Hornet Cockpit Set

Kit Contents

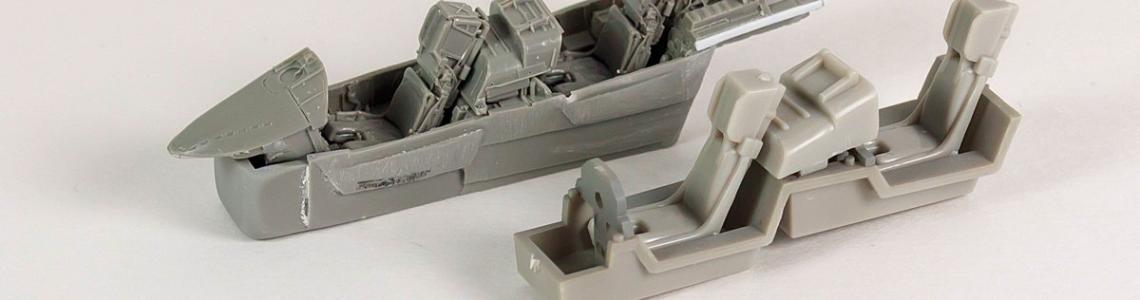

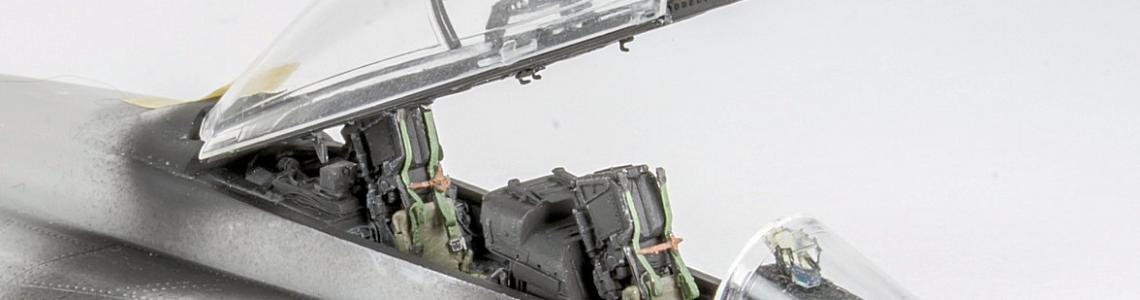

Those modelers who have previously built Hasegawa’s F/A-18F Super Hornet will be very familiar with one of it’s weakest areas - the cockpit. Hasegawa’s cockpit is very simplified with basic ejection seats and decals for the blank instrument panels and side panels. The busy “turtledeck” behind the rear ejection seat is represented by only a flat plane, and the canopy’s internal structure is limited to the rear portion of the frame, omitting the center brace.

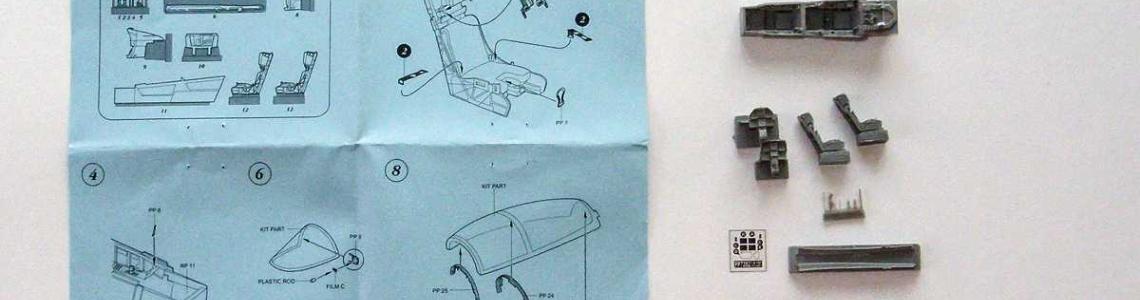

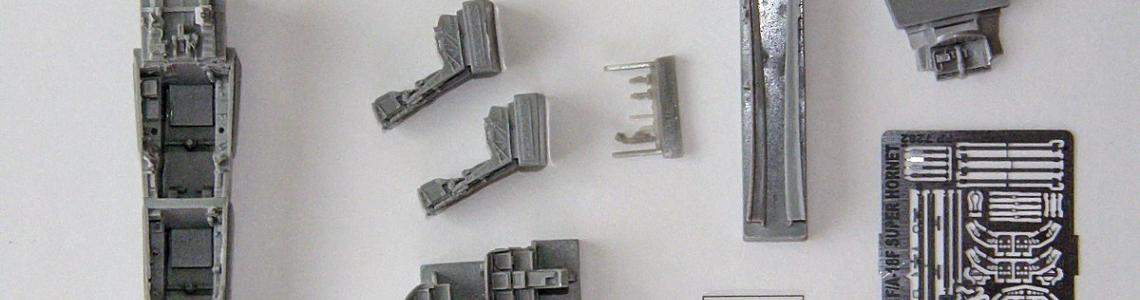

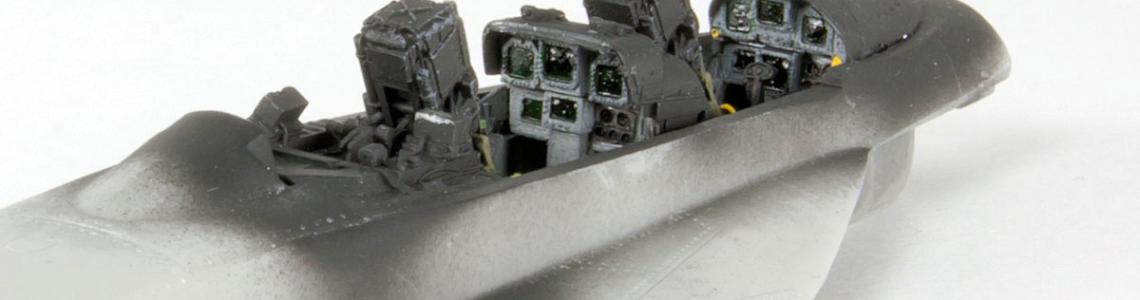

Aires has offered a fantastic upgrade for Hasegawa’s F/A-18F kit with their beautifully cast resin cockpit replacement set. The cockpit set contains approximately 40 parts, 13 cast resin parts on 8 casting blocks, a photo-etch (PE) fret, and a clear film sheet with HUD “glass” and instrument faces, and a detailed two-sided instruction sheet. The castings are crisp and flash free. The cockpit tub itself is nothing short of a work of art, featuring fine switches and sidewall details. The instrument panels and cowlings also raise to the level of artwork, with the “glass” cockpit featuring even the small buttons on the edges of the various instrument display screens.

One note of importance to modelers is that Aires’ F/A-18F cockpit represents the Block I Super Hornet rear cockpit, which is nearly identical to the front station. The Block II F/A-18F and EA-18G Growler were delivered with the Advanced Crew Station (ACS) featuring a large center screen in the main instrument panel as well as an additional screen above the instrument cowling for the Weapon Systems Operator in the rear cockpit. Recent Hasegawa Super Hornet kits representing the Block II aircraft have an alternate rear cockpit cowling, Part R4, with the additional upper screen that the industrious modeler could use to modify Aires’ cockpit to represent this later ACS cockpit.

Construction

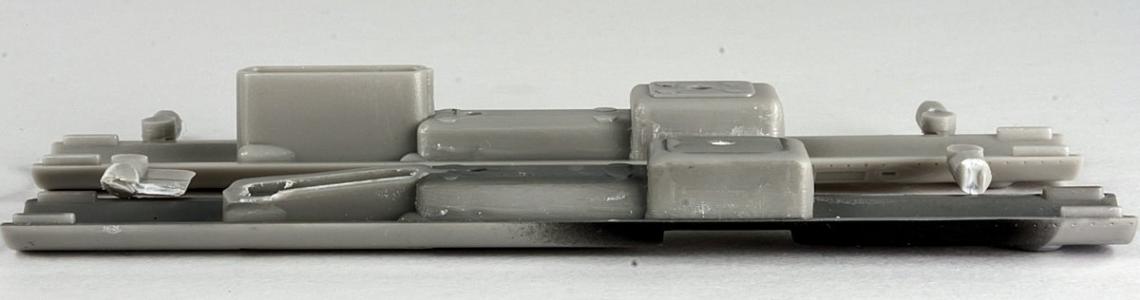

The first step when working with any resin parts is to remove them from the casting block and Aires has made this very easy as the instructions clearly identify the areas of the casting that will need to be removed so there is no guess work involved with what stays and what goes. The casting blocks were very well thought out and thus very easy to remove. I used a small razor saw to free the parts and quickly had the job finished, although it may be possible to use a standard hobby knife to repeatedly score the attachment points, but will likely require much more work. The standard caution when working with resin parts applies here: the dust from cutting and sanding is poisonous and care should be taken to avoid breathing it in while working on the parts, as well as remembering to dispose of the dust residue afterwards. Once removed, assembly of the now freed parts is performed in several sub assemblies, which are brought together onto the base kit.

The meat and potatoes of the build will be fitting the cockpit tub, Part RP 11, into the kit’s upper fuselage, Part A3, and as the instructions accurately point out, “Thinning of the plastic parts and dry-fitting of the assembly needed!” The kit’s upper fuselage will need some major modification to accept the resin cockpit tub. As called out in Aires’ instructions, the existing front instrument panel cowling will need to be removed entirely from the kit. Not mentioned in the instructions is the need to remove the center divider between the front and rear cockpits on the upper fuselage (This is the attachment point for the rear instrument panel cowling, kit Part F1 or R4 depending on the version of the kit). Additionally, on the upper fuselage once you’ve attached kit Part F3, the area between the rear cockpit hole and the start of Part F3 will need to be removed to allow the “turtledeck” area behind the rear cockpit in Aires’ tub to settle evenly with the side rails.

Once the kit’s upper fuselage has been initially modified, a great deal of sanding and material removal will be needed to allow the cockpit tub to slot into place. Sanding started on the outside of the cockpit tub’s sidewalls until they were as thin as seemed prudent. It will be very easy to sand holes into the cockpit sidewalls, so extreme care is needed. A bit of material also needs to be removed from the front upper edges of the cockpit tub for a good fit. Once the tub is thinned as much as you dared, work turns to sanding and scraping the area below the kit’s cockpit side rails on the inside of the upper fuselage. A great deal of thinning is needed, but it never felt as if there was any danger of breaking through the kit plastic. After quite a bit of work, test fitting, work, test fitting, repeat, the cockpit finally settled fully in place.

Once the cockpit is in place, the fitting of the resin front instrument panel, Part RP 9, will need to be addressed. It needs to sit low in the upper fuselage less it (and the HUD assembly, Parts PP 14 & PP 15) interferes with the kit canopy windscreen, Part J2. Once again, slowly working, test fitting, and repeating until right will yield great results. Some filler may be needed depending on how precisely you removed the kit’s instrument panel cowling, but fit is crucial here, so better to fill than have it sit too proud, which also holds true at the rear “turtledeck” area.

The final point to bear in mind regarding the Aires’ cockpit tub is that it is not mounted in the same way as Hasegawa’s kit cockpit inserts during the regular assembly, so be sure to take this into account when performing Hasegawa’s assembly Steps 2 and 3. Specifically the nose bottom panel/front wheel wheel, kit Part B7, will need to have a large section of the kit cockpit attachment point removed, and a slight rise sanded down, as seen in the photos. The bottom of the resin cockpit tub may also need to be sanded to some extent. Repeated test fitting will be required for a perfect fit which is required in this complex assembly area of the Hasegawa Super Hornet.

The ejections seats are molded in one piece with the straps and ejection handle as separate PE parts. The shoulder straps are a multi-part affair, requiring some complex bending for a natural “draped fabric” look. One helpful note is to attach the lower shoulder straps, Part PP 3, to the seat first, and then bend the upper straps, Parts PP 1 & PP 2, to meet the lower strap in place.

The kit canopy will feature a great deal of detail from this set: side rails, interior framing with mirrors and grab handles, latches, a center cross brace, and a detailed rear frame with actuator detail. Assembly of all of these parts can be quite complicated. Bringing all of these parts together can present some issues if you want to assemble your Super Hornet with the canopy closed. Notably, the rear frame, Part RP 10, must be attached to the two side rails, RP 6 & RP 7, while they all lay flat against the kit’s side rails as well as the “turtledeck” at the rear of the cockpit tub, Part RP 11. Failing to do so will leave you with a canopy that won’t sit in the closed position. In addition, this would also be the same time to form, tweak, and attach the center cross brace, Parts PP 21& PP 22 & PP 23, as it must clear the rear instrument panel cowling, Part RP 8. If the canopy is to be placed in the open position, as I chose to do in this review to show off the great detail, the fitment is far less critical and can be done directly to the canopy itself.

The cockpit set also features some detailed internal canopy frames, Parts PP 24 & PP 25, which will need to be bent and attached directly to the kit canopy. Very judicious use of small amounts of CA glue on a Future-coated canopy can be used to attach the framing as they will be overpainted on the outside of the canopy effectively covering the glue marks. I found the best way to attach these parts was to first bend them into a horseshoe shape, then attach the center of the frame to the very top of the canopy. Once this had cured fully, the part could be carefully bent to the interior contour of the canopy and attached with glue at each end.

The rest of the assembly work is characterized by working with various small PE parts to create rudder pedals, handles, and the very delicate HUD assembly that features two pieces of clear film for the combining glasses (over which I applied a layer of Hasegawa Polarizing film for a more realistic effect). Some of the parts, notably the two auxiliary compasses, part PP 9, on the canopy frames proved too small to work with easily, and ended up lost to the carpet monster. A steady hand and previous PE experience will be required to fully deck out the cockpit in the various smaller bits, but even without 100% of the various tiny bits installed, the cockpit set shines.

Painting

It’s important to wash all of your resin parts in warm soapy water (not hot, the parts may deform in hot water) to remove the mold release agents. Skipping this step will make paint adhesion problematic.

The overall cockpit interior is finished in the standard US cockpit color, FS 36231 - Dark Gull Gray. The sidewalls and switch panels on the side panels are mostly flat black on the real Super Hornet and once painted, even painted in Testos Aircraft Interior Black (a “scale effect” flat black), and drybrushed they looked far too stark. Using a wash of Vallejo Dark Grey Wash over the Dark Gull Gray in these areas made for a much nicer effect, although this is clearly taking artistic license. The same wash over the instrument panels helped make the actual 3D nature of the rather flat looking “glass” cockpit pop out . The molded switches on the various side panels were then drybrushed with a light gray to make them stand out, and a few of the various yellow emergency switches were picked out using a toothpick. A final touch was painting the various “glass” cockpit instrument screens black and then following that with a coat of Tamiya Clear Green to give a more accurate look to the powered down gauges.

The remainder of the cockpit, everything above the frame rails and the ejection seats, were painted Aircraft Interior Black and drybrushed with dark gray. The ejection seats feature a myriad of colors on the seat cushion, back and belts, ranging from olive drab to gray and bronze fabric belts. An invaluable reference for painting the cockpit and seats, as well building and detailing the entire cockpit and Super Hornet, is Jake Melampy’s The Modern Super Hornet Guide: The Boeing F-18E/F & EA-18G Exposed.

Conclusion

Aires has created a fantastic upgrade to Hasegawa’s F/A-18F kit. Despite the advanced modeling skills needed to work with the resin parts, the night and day difference over the kit parts make all of the extra work well worth it. It’s somewhat hard to believe that so much detail can be packed into 1/72 scale! I was quite impressed. This rates as an absolute “must have” when building the two-seat Super Hornet.

My thanks to Aires for providing this fantastic upgrade set as well as to IPMS/USA for the chance to review it.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews