F-4C/D Phantom

I must be one of the few modelers left that hasn’t built at least one of these since this kit was introduced more than thirty years ago. The 1/48th F-4, along with the Century Series and Naval Aviation jet aircraft molded by Revell and Monogram back in the 1970s and 80s are truly classic models: exemplified by outstanding detail throughout (for their day), but particularly in the cockpit and wheel wells; finely raised panel lines, and the sometimes less than stellar fit of some of the component parts. All of this offered at a consistently affordable price.

This particular version of the venerable F-4 has been in and out of production a number of times since 1979. This kit represents the latest incarnation. A quick glance at the inside of the wing or the underside of the tailplane will confirm this kit’s ancient lineage, as well as something new about this particular molding’s place of birth.

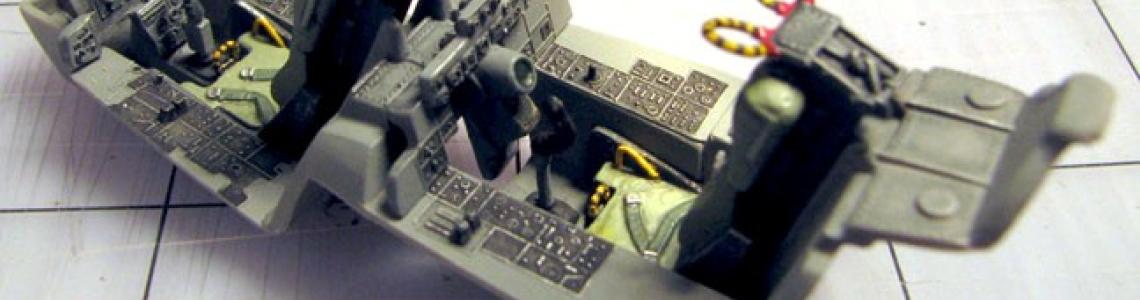

Like most aircraft builds, this one begins with the front office. This is a simple but beautifully detailed arrangement of the Air Force Phantom cockpit, with finely raise-detailed front and rear instrument and side panels. Decals are included for both instrument panels, but these areas lend themselves nicely to painted instruments with some light dry brushing to highlight the detail. The ejection seats are designed in such a way so as to make substitution with resin replacements difficult. The seat backs are separate pieces, but the bottoms are molded in as part of cockpit tub. When assembled, the fit is very good and you’d never know how they went together. The seat belts are molded in place, but are well detailed, as are the overhead ejection grab handles. The only additions that I made were the seat side handles and the between-the-legs ejection grab handles, all made from short lengths of wire.

The only disagreeable fit in the cockpit area is at the rear where the cockpit tub meets the fuselage interior. There’s a significant gap there. Even if you close the canopy, it’s still visible, so it’ll need to be filled. It’s a tight spot with some compound interior curves that could be difficult to smooth out. This is a place where the two-part modeling putty Magic Sculpt came in handy. Once roughed into place, it can be smoothed with water to a very fine edge. There was little need for subsequent sanding to smooth the joint once the putty had dried.

It’s during the assembly of the fuselage that we see the major differences in design between nowadays and thirty years ago. Parts that straddle the centerline such as the nose cone and arrestor hook (yeah, Air Force Phantoms carried this legacy of its Navy origins throughout its career) are molded as part of the fuselage halves instead of separate pieces. Other more recently designed Phantom models (and even some older ones) generally include these as separate pieces, saving a lot of clean up time.

The fuselage fit, as well as the wing-to-fuselage join is generally pretty good. Careful sanding and dry fitting of the edges where the wing top meets the fuselage sides eliminated most of the need for filler there. A little filling and sanding was needed at the front and rear attachment areas where the wing underside joins the fuselage. On the other hand, in spite of significant clean-up of the mating surfaces, considerable sanding (more like carving) was required on the back end of the fuselage join to smooth out the resulting seam on the hook and scalloped plating of the rear fuselage. On the positive side, the upper fuselage panels lined up perfectly once the fuselage halves were mated. Careful sanding of this very slight seam preserved nearly all of the raised panel line and rivet detail here. Only the circular panels that straddled this seam were sanded out. These were easily rescribed with a circle template.

Attaching the splitter plates and the intakes is the first of a few particularly bad fitting areas. Initial dry fitting led me to believe that these parts must belong to a different kit altogether. Nevertheless, I marshaled an array of clamps, wedges, rubber bands and a blow dryer to force these four parts to assume their proper attitude. Rube Goldberg would have been proud of my less than elegant solution to attaching the intakes, but like any landing that you can walk away from, it got the job done.

Another major area of disappointment is where the burner cans fit into the aft fuselage. These parts are about one inch long and fit part way down into the fuselage cavity. The petals, molded fully open, are detailed inside and out, but there’s nothing but a blank wall at the bottom of the can. While not readily visible, if you want to see any detail down there, you’ll have to make it and put it in there yourself. However, it’s the fit of the cans into the fuselage that has you checking the instruction pages twice to make sure you haven’t left something out of the assembly process. It’s almost as if the model designers got to this point, and then went on a coffee break and forgot where they left off when they returned. There’s really nothing back there to fit the cans into except a big, open hole stretching from one side of the fuselage to the other. There are no positive alignment points. The cans just squeeze into this rather ill-fitting opening, and it’s left to the modeler to determine the proper length and angle where the cans come to rest. The edges of this opening are a poor match to the round shape of the cans, so be prepared to do some reforming there to give the cans something to conform to. If pushed in as far as they will go, the remaining exposed nozzle seems too short, but if you pull them out just a bit, that leaves a very noticeable step between the fuselage side/bottom and the exhaust nozzle, which in reality should be a fairly smooth transition. I opted for the short nozzle. In any case be sure you have some good references. The fuselage framing between the two exhaust nozzles and forward of the arrestor hook will also need to be extended with a couple of pieces of scrap plastic to close up a visible opening there.

The last of the kits noticeable weak fits is the attachment of the “all-moving” tailplanes. The parts themselves were molded with the precision of a pair of used paper cups joined at the mouth, requiring considerable sanding to get the proper anhedral angle and reduce the attachment gap to something close to the correct proportion. The attachment tabs are supposed to help ensure the correct droop when both the tailplanes are in place, but no amount of persuasion on my part could convince them to sit any better than too shallow on one side and too steep on the other, or vice-versa. I cut the tabs down to short nubs and applied a liberal helping of old fashioned tube glue to keep them in their proper place. Sometimes the old ways really are the best.

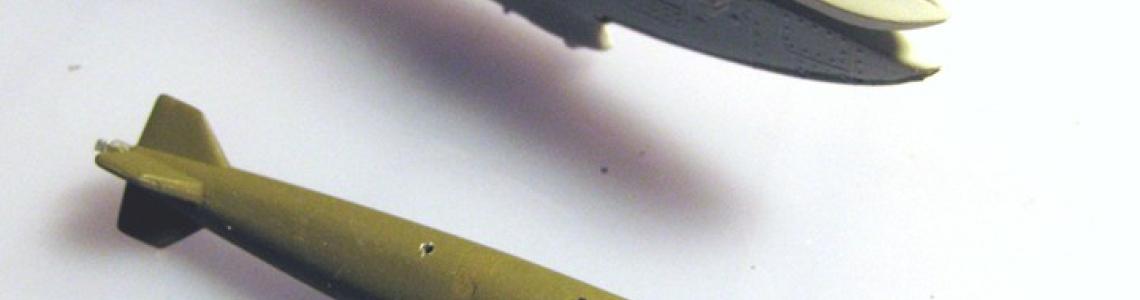

The kit supplies a variety of ordnance, including a complete suite of AIM-7 Sparrows and AIM-9 Sidewinders (4 of each); wing tanks; a belly tank; a centerline Vulcan gun pod; two different ECM pods, and a strike camera. I wanted to build this Phantom to reflect its air-to-ground role with a variety of stores. I used the centerline gun pod and added six 500-lb MK82s on TERs from the spares box, as well as two Sparrows in the rear bays; with the AN/ALQ-87 ECM pod and strike camera up front. Since I had no sway braces to use with the bomb racks, I chose to add attachment pins made from short bits of wire inserted into the bombs and racks to provide positive attachments.

The large kit decal sheet provides markings for two post-Viet Nam aircraft from the 58th Tactical Training Wing. These were still in SEA camouflage, but with either black/white or red/white “candy stripe” wing and fuselage ID markings. These were a bit too gaudy for me, and I wanted to model a VN era bird. My research led me to the 366th TFW, the “Gunfighters” flying F-4Cs based at Da Nang in 1966-67.

The 366th performed a lot of ground support work, and at that time used non-standard tail codes that didn’t conform to the current PACAF system. The first letter (A, B or C) represented the specific squadron, with the second letter representing the individual aircraft, based on the “assigned” pilot. With some letters from spare decal sheets, this allowed me to personalize my Phantom with my own initials (“BK”) for an aircraft from the 390th TFS. The tail code numbers and all of the stencils and warning markings came from the kit decal sheet. They’re a bit thick, but usable and abundant.

This kit is a lot like an old, old friend who can be a real pain in the butt at times. Its strong points of detail, accuracy of shape and affordability make it worth the effort. With some patience and work, it can be built into a real showpiece, but the average modeler can make this Phantom into something they’d be proud to see on their shelf, and this venerable kit readily fits in to my quarter scale Viet Nam collection.

Thanks to IPMS and Revell/Monogram for providing this model for review.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews