F-35A Lightning II

Background

The absolute latest in American manned fighter aircraft, Lockheed Martin's F-35 Lightning II is slated to replace aging F-16, F-18, and AV-8B aircraft in the lightweight fighter attack role in the US Air Force and US Navy in the next several years. The land-based F-35A will replace the F-16, the vertical-takeoff F-35B will assume the Harrier's role, and the carrier variant F-35C will take over for the F/A-18. Several other nations, including the United Kingdom, are expected to purchase variants of the F-35 for their air arms. This fifth-generation fighter employs many advanced features, including low-observable (stealth) technology, to ensure its effectiveness in the 21st Century combat environment.

The Kit

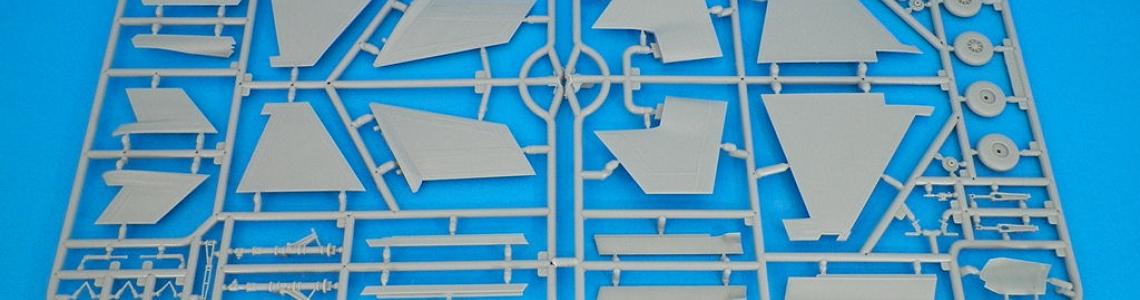

This recent release of the F-35A from newcomer Kitty Hawk follows their F-35B and their initial F-94 series launched earlier in 2012. Molded in sturdy light gray plastic with crisp, recessed surface detail, a sprue of clear parts, a fret of well-executed photo etch, and a couple sheets of decals, the kit offers the modeler a good bit of product for the money. Weapons options include JDAM, AIM-120, and AIM-9X. Optional external pylons are also included. Markings and color guides are included for aircrew and maintenance training birds from the 58th Fighter Squadron of the 33d Fighter Wing based at Eglin AFB, Florida, and for the first production F-35A based at Edwards AFB, California.

The Build

Although quite attractive in the box, the build posed a number of unexpected challenges, based on expectations set by Kitty Hawk’s earlier F-94 release. A significant amount of work was required to yank some of the elements into a gallery- or competition-worthy finished product off the bench. Also, part numbering in the instructions is unreliable and requires constant dry-fitting and fit-checking.

Cockpit assembly was straightforward with no surprises. Tub, seat, and touch-screen (decal) instrument panels appear accurate to internet photos of the simulator, and the PE provided for seat harnesses, ejection handle, and canopy rails and locks is spot-on. No interior color callouts are provided in the instructions, but standard modern USAF colors (Flat Black and Dark Gull Gray) are evident in the online references.

The nose wheel well, though nicely detailed, exhibited significant mismatch in male/female tab alignment, resulting in removal of the male tabs. Similar mismatches were seen in subsequent areas of assembly; the nose strut is nicely detailed, but the nose wheel appears rather bulbous and doesn’t jibe with photos of the prototypes.

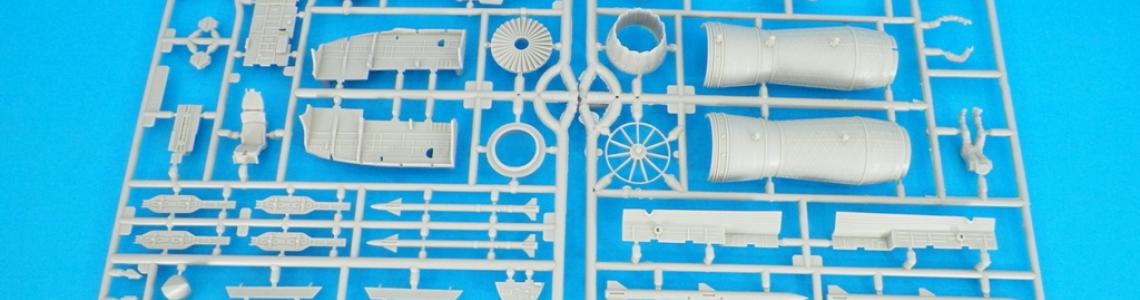

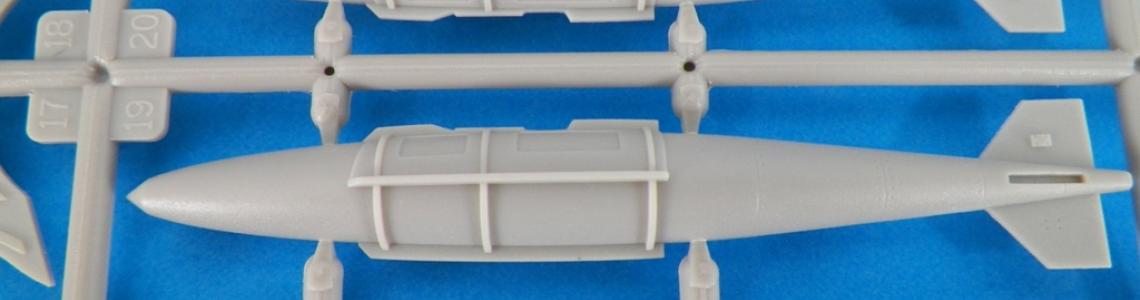

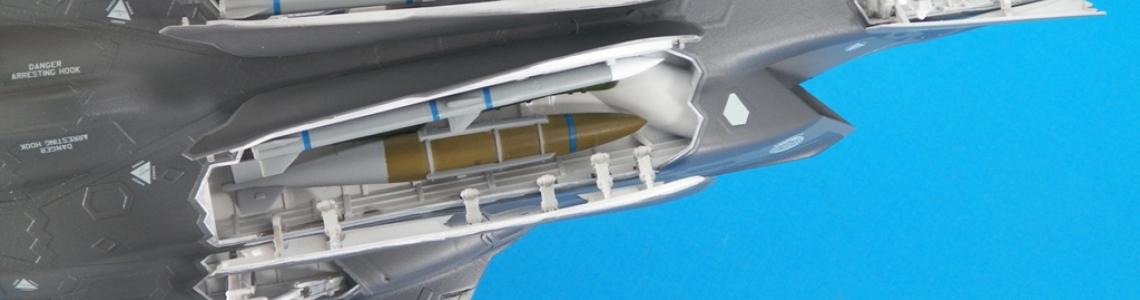

Weapons bays and main wheel wells and struts follow suit with equally-nice detail and inaccurately-bulbous tires. The bay doors are marred with 3 to 5 ejector pin marks apiece, and require some careful attention so as not to mar the otherwise decent interior detail. Overall fit was good, but clamps were required to coax the slightly-warped fuselage bottom into alignment when the bays were glued in. Again, color callouts were largely omitted, except for the Interior Green conduit running through each weapons bay. Gloss white was used. AIM-120 AMRAAM, AIM-9X Sidewinder, and GBU-12 JDAMS are included. JDAM and AIM-9X detail is crisp and convincing, but the AIM-120 detail is a tad soft by comparison, but still usable.

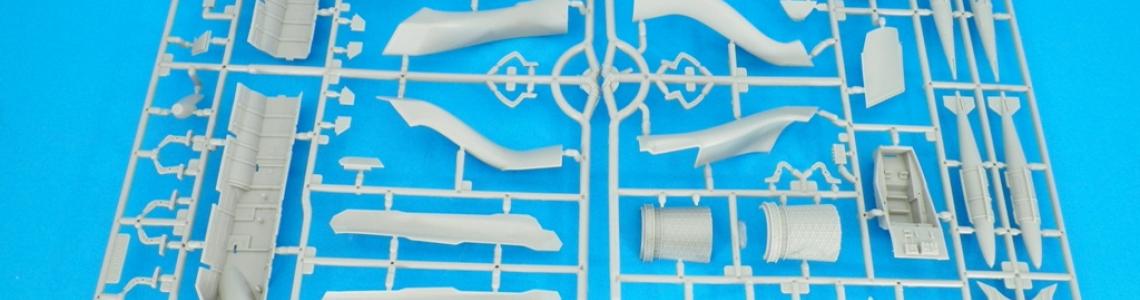

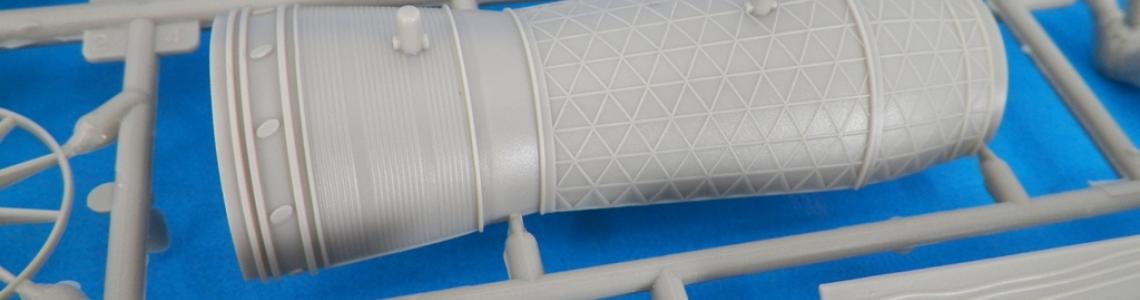

Kitty Hawk provides full intake ducts and a detailed engine casing, first stage compressor blade, and afterburner can detail. Engine assembly is straightforward with decent fit. PE is also included for the afterburner flameholder and nozzle “turkey feathers.” Although a bit tricky to form, the turkey feather PE provides a huge aesthetic “bump” above the detail level embodied in the optional injection molded part.

All subassemblies to this point fit nicely into the lower fuselage, and after a little dry fitting and tweaking of the lower and upper fuselage halves, the fuselage assembly was completed with little fuss.

Wing subassembly was pretty uneventful, with separate leading and trailing-edge flap elements. Integrating the wings to the fuselage, however, required 30-45 minutes of dry fitting, sanding, scraping, and coaxing to minimize visible seams and maintain alignment. Curiously, Kitty Hawk includes apparent female locating features on the inside half of the upper wing, with no male counterparts on the inboard lower wing stubs protruding from the fuselage assembly. Furthermore, these “features’ interfere with proper fit and alignment of the wings to the fuselage. Needless to say, they were removed with extreme prejudice.

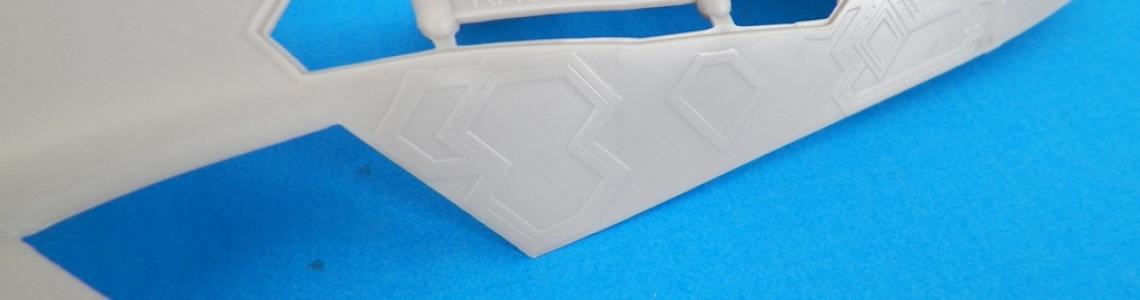

Horizontal stab assembly and fit to the airframe was very clean, but the vertical stabs posed yet another challenge. For reasons unknown, the tool designers at Kitty Hawk engineered the vertical stabs in a manner resulting in a large and prominent seam on the inboard airfoil surfaces which are extremely difficult to fill and blend – even more so if other surface detail is to be preserved. Three to four passes were made on each stab to blend the seam sufficiently, with some toll taken on surrounding detail. Once the seams were subdued, a little bit of dry fitting and sanding/scraping of the bottom gluing surfaces yielded a good fit with minimal seam at the base of the stabs.

Painting and Finishing

The kit includes a nice full-color painting and marking guide for the two subject aircraft in their “delivery livery,” but photos of the in-service prototypes show a much more complex and visually interesting scheme, namely around the variation in colors of the radar-absorbing materials (RAM) used on service panel lines, sensors, and various parts of the airframe. Basic color callouts are for Gunze and appear accurate to reference photos. I chose to use Model Master Acryl (FS36118 Gunship Gray and 70/30 mix of FS36270 Neutral Gray to Gunship Gray) in place of the Gunze.

Given the prominence (and inaccuracy) of the raised areas along access panel edges and the “factory-freshness” of the actual prototype, I chose to forego my customary pre-shading. After a base of Tamiya gray primer, the 70/30 mix of Acryl grays was applied and allowed to set overnight. After tedious masking and cutting of the lighter saw tooth panel access areas, radome, leading edges, and select panels, the Gunship Gray was applied. Once unmasked, Minwax Acrylic Clear Gloss was laid down as a decal base.

Decals were applied using the Microscale System and conformed beautifully with no hint of silvering – some of the best seen to date. Once set, the decals were spot-sealed with more Minwax Clear, followed by some pin washes in targeted areas to add visual interest without making the aircraft look overly worn. A 75/25 mix of Model Master Acryl Clear Flat and Future was misted on in 3 light coats to achieve the desired final sheen.

The canopy, molded in clear, received three attempts at tinting with unsatisfactory results, so it was just left in its natural untinted state to meet review and contest deadlines.

Conclusion

First out with a serious quarter-inch scale kit of the production F-35A, Kitty Hawk offers a cutting-edge subject for the advanced aircraft modeler. Despite numerous challenges and flaws, the kit builds up into a convincing facsimile of the prototype with a bit of patience and elbow-grease, and the completed review sample was very well received at its debut at Blizcon 2013 in Columbus, Ohio.

The kit is recommended for modelers experienced in sorting through fit issues and instruction ambiguity. Less-experienced or time-constrained modelers are likely to experience a significant degree of frustration or disappointment with the kit, and would be well advised to temper their expectations for a speedy or problem-free build.

Many thanks to Kitty Hawk and IPMS/USA for the sample kit and the opportunity to review it.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews