F-14D cockpit in 1:48

Thank you to the Eduard Company for sending this cockpit after-market set for review, it is always a pleasure to see what your new products bring to the scale-modeling world. Thank you also to the IPMS Reviewer Corps staff members who do the hard work in getting us modeling products to review, the reviews posted, and the news spread to the world.

Summary

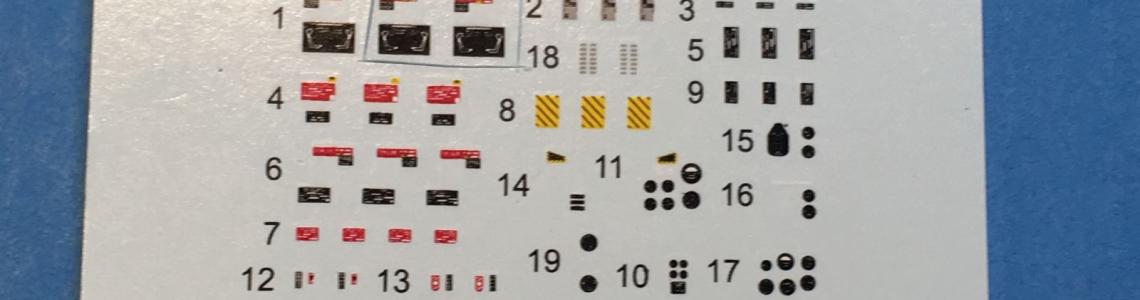

This aftermarket set from Eduard is a superb addition to the already excellent Tamiya F-14D kit. The Eduard set simplifies construction of the cockpit area and adds a very high level of detail that only exceptional resin casting can provide. Assembly was nearly flawless. The only problems were of my own doing. A small color-etched fret and a brass PE fret accompanied the numerous resin parts, with additional details provide by a small decal sheet for the NACES seats and instrument details. Acetate film cutouts are included for the HUD panels.

General Comments

The set arrived in a 6.5 x 3.4 x 2 inch cardboard box with foam inserts protecting the PE and clear film separately from the three bags of resin part. A three-page set of instructions are included in A4 size (a bit smaller than letter size) in color, printed front and back. The resin parts had no obvious mold release, however I did soak them in undiluted Simple Green cleaner for 24 hours to make sure there was none remaining.

The pour plugs are clearly labeled with part numbers, a very nice touch. The removal cut marks on the larger pour-stubs are straight, not like some zigzag ones I have “muttered” about in the past. The straight-line cut marks are a nice practical design feature for the modeler. There is a part R16 and a part R23 included on pour stubs, but they are not used.

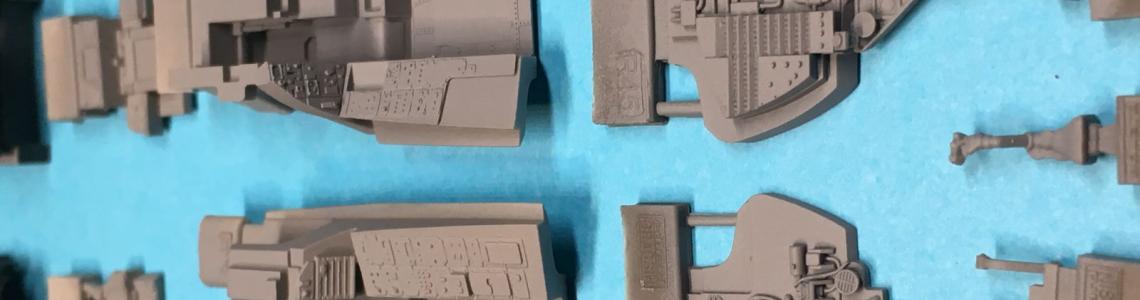

Pre-construction review of the parts indicated that the majority of the set is a complete replacement of the kit cockpit. Tamiya kit instruction steps 1 through 6 are largely unneeded. I first appreciated the real value of the Eduard set at this point. The kit has many little parts that are very nicely detailed. The Eduard set is considerably simpler to put together and has a much higher level of detail. However, with that said, painting the Eduard set requires a bit more of a steady hand to bring the detail out. No references to kit parts appear until Eduard step D. Only a few modifications to the kit parts appear on Eduard instruction page 6, step D.

Recommendation

I highly recommend this upgrade set from Eduard for ease-of-use, accuracy, and value. The Tamiya F-14D kit is excellent, but the additional cockpit upgrades improve the final kit presentation. The set requires moderate PE skills, and little fitting to achieve and excellent result. The cockpit matches exceptionally well with NATOPS F-14D documentation. A detailed build log follows this review. Thank you again Eduard and the IPMS Reviewer Corps!

Build Log

- Paint notes:

- I relied extensively on F-14D cockpit panoramas available on the National Naval Aviation Museum (NNAM) website (see references below).

- The interior was painted FS36231.

- A black Sharpie© dulled down the back of the color PE set to reduce reflectance.

- PE belts look a bit too yellowish; dull them with a brownish wash? No need, colors looked OK when on khaki seat.

- German Gray was a good match with NNAM images. NACES seat frames were painted this color.

- Black to dark gray washes used throughout to highlight details.

- Light gull gray detail suggestion appear throughout the instructions. I minimalized use of light gull gray based on my reference images.

- Khaki seats cushions appear in the NNAM images.

- The NNAM images show a well-used and worn cockpit with low color contrast. I attempted to replicate this in my build.

- P. 1/6 - inventory and suggested colors appear on this page

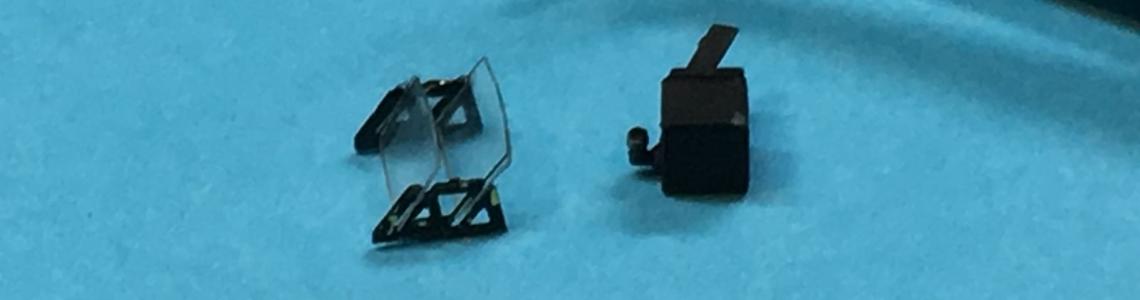

- P. 2/6 - Assembly A - NACES build up.

- I considered leaving the seats on the pour plugs for a good work base. However, after looking at the detailing required, I could not envision sawing the seat off the pour plug without damaging previous work. Careful razor saw work sent the plugs to the scrap pile. The resin has a great balance of workability and firmness.

- The seat cushions (R53) fit perfectly with little clean-up needed.

- The canopy penetrators are different on the forward seat and the rear seat. The shorter penetrators (R55 and R57) are on the rear (RIO) seat. Pay attention to the where you place the seats in step D on the last page of the instructions. Generalized NATOPS illustrations show the penetrators the same on each seat, but reference photos clearly show the difference.

- The belt color did seem a little bit too yellow, but putting a brownish wash would take away the color-etch patterns (see paint note). The color PE did not delaminate.

- The emergency oxygen operating handle (a small loop) is shown on the final assembled seat drawing, but is absent on all previous drawings; no PE or other part is included for this handle as shown. The handle can be easily scratch built if required.

- Extra ejection control handles are included! This is very reassuring, given the small size of the part, and my ability to ineffectively use the little stuff. Whew, PE parts 2, 6 were installed uneventfully, with medium eye stress, and PE parts 4, 7 (leg restrain lines) were held off until just before seat installation in the cockpit. PE2 is a safety pin, so the seats are “scale-safed”.

- Do not forget to trim out the light webbing that fills in the right side ejection handle.

- Decals went on without problem, responding well to Microscale solutions. Eduard provided an extra decal or two in most cases. I REALLY appreciate the extras.

- P. 3/6

- Lot of pour plugs were trimmed off and fitting completed before painting. I did leave the pour plugs on the side panels for painting handles.

- Most of this step is painting and detailing, with some decals, in the back (RIO) seat.

- The decals in this step are very tough to position; be sure to have the surface prepped well with solution. Decal 17 has several gauges on a single carrier piece, and you may wish to trim them out and apply individually. I lucked out, and they came out just fine.

- The painting suggestions generally follow my reference images.

- All of the cockpit details are well represented based on comparisons to a NATOPS F-14D manual.

- Parts assembled very cleanly, with minimal cleanup after removal from pour plugs.

- I painted for effect, not “perfect”, based on the well-worn “offices” in my reference images.

- P. 4/6

- The front seat assembly did not significantly differ from the rear seat overall, just with different parts.

- All of the cockpit details are well represented as on the previous page, based on comparisons to a NATOPS F-14D manual.

- The sensor switch box (R40 & PE26) was assembled, and left off for later.

- P. 5/6

- In step 3, the dimples in the center console side plates (PE 21) are convex inward. This will not be a problem if you pay careful attention to the instructions.

- I did not glue in the shroud (R47) right away, leaving it for fitting with the rear cockpit later.

- Any part that projected upward, e.g. PE 26, was left off until final assembly and painting of the entire kit.

- P. 6/6

- I had concerns about using the extended option for the refueling probe. Will the extended refueling probe option work with resin set? Kit part D34 in kit step 7 extends into the cockpit well and I thought there might not be enough room with the resin parts. However, the resin part do fit well with D34, albeit very tightly.

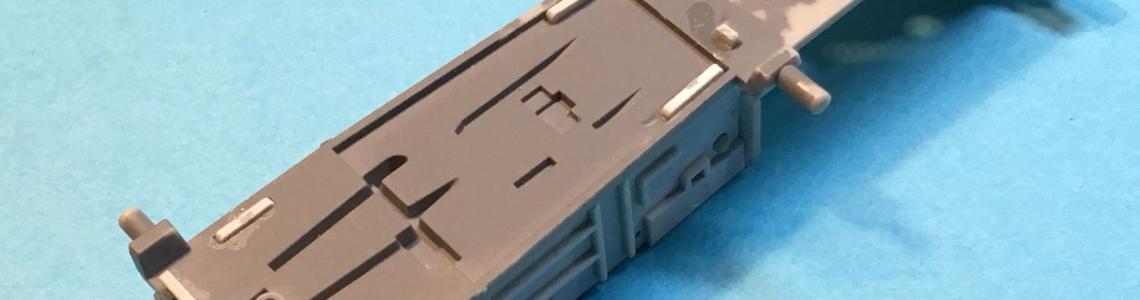

- The notches in the front and rear cockpit tubs are very nice for part alignment. I think the overall cockpit assembly is much more solid because of this design.

- I suggest dry fitting the cockpit in the order of front to the nose well base, followed by the rear cockpit to the nose well base. The front of the rear cockpit base is where the pour plug attachment is, and where the most filing/sanding/fitting is possibly needed. I also suggest placing the shroud (R47) but not gluing until after the rear cockpit is cemented in place. This is opposite of the directions order.

- The nose gear walls (kit parts G36, G37, G38, and G39) have attachment tabs that extend above the well floor (kit part G34). I needed to trim these tabs flush to make a smooth surface for the Eduard parts to sit flush on the well floor. Furthermore, the Eduard instructions call for adding some small shims to the base of each cockpit. The shim dimensions are included, but the shim locations are not given, other than a general position on the cockpit bases. If the well floor is smooth, then the location of the shims is not critical, so long as the shims are placed in the correct area. Alternatively (I did not do this), it might be possible to put the shims on the well floor first, then cockpits.

- I built up the resin cockpit on the nose well base (kit part G34) and was able to center and align the resin parts very effectively. I dry fit the assembly into the fuselage halves, and had nearly perfect centering of the resin cockpit with in the kit fuselage halves. This is a rare success for me in using aftermarket cockpits! Go Team Eduard!

- Finalizing

- Incorporating the completed cockpit into the model (kit instructions step 18) was virtually flawless. However I made a mistake after gluing up the cockpit nose halves (kit parts B1 & B7). This mistake is NOT related to any of the Eduard or the Tamiya parts. The kit cockpit floor or nose wheel well (kit part G34) has locating tabs and pins that must be snugly seated in the fuselage halves. I failed to test fit adequately and the submillimeter mistake caused problems placing kit part D17. A little bit of tweaking, scalpel work, filing and creatively directed profanity resolved the issue! In hindsight, a way to avoid this problem is to complete the Eduard cockpit up to the point where kit parts are used. Complete the Tamiya kit up to step 18, then return to completing the Eduard set. This change in assembly order will allow more effective test fitting.

- I planned to have the canopy raised/open. I noticed there wasn’t quite enough room for the canopy to fit snugly fit over the ejection seats. Had I chosen to close the canopy, I should have test fit the NACES better and sanded the seat bottoms more to ensure a good fit of the canopy. My bad!

- I stopped drinking coffee for a week, sharpened my tweezers, and dusted off my ship-in-a-bottle skills before adding all the tiny handles, levers, knobs, etc., that I would have flattened during the construction. Similarly, the HUD and the sensor/switch box on top of the panel shrouds were also left for attachment much later in kit assembly. The Thumb of Kong was thwarted!

- What a fun build!

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews