ERA-3B Skywarrior, Part 2

This is the second installment, “Full Build,” of Trumpeter’s Douglas ERA-3B 1/48th scale variant to be released by Trumpeter in 2016. This plane represents the US Navy, VAQ-33 ‘Firebirds’, ERA-3B, 104/GD BuNo. 146447. The ERA-3B variant was converted from the RA-3B variant as an electronic aggressor aircraft serving with the VAQ-33 and VAQ-34. This variant follows Trumpeter’s release of the A-3D-2 Skywarrior Strategic Bomber 02868 in 2013 and its EKA-3B Skywarrior 02872 in 2015. The model will be based upon the US Navy, VAQ-33 ‘Firebirds’ plane as seen on page 49 in the “A-3 Skywarrior in action book, Jim Sullivan, Aircraft Number 148, Squadron/Signal Publications”. Jim Sullivan’s depiction of the picture states that this plane is sitting on the flight line at NAS Oceana Virginia on 12 May 1977.

This is a full model build straight out of the box with no aftermarket accessories used. However, I did order Eduard’s paint mask. I seem to have a problem masking the canopies. There are several aftermarket accessories available to add more detail during the build if the modeler chooses. Included in the Part 2 build will include Steps 1-13: construction of the cockpit, radar, main landing gear, right and left main undercarriage, ECM bay, left and right gear cabins and concluding with adding the internals. As with all builds, I prefer to review the instructions and put together a plan of action. As mentioned in my “First Look” there are some areas of the sprue parts that need addressed prior to the build. One in particular was the ejector pin release points on the inside of the fuselage. However, as modelers we do not follow the instructions step-by-step, we tend to skip around. Who likes to wait for parts to dry? Certainly not me. During this stage of the build I did noticed how soft the plastic was. Careful cutting, snipping and sanding is essential. So, on to the build.

Step 1: The instructions have you to build the bulkhead by attaching the power distribution panel, time meter, aft power panel, fourth man’s seat and other small equipment panels located on the aft bulkhead including some PE. The bulkhead was painted with Vallejo Model Color 70.842 Gloss White and electronic equipment painted with Vallejo Model Color 70.861 Gloss Black. Dials were painted with Vallejo Model Color 70.997 Silver and Tamiya X7 Red. During step 1 I didn’t have in any problems other than some clean up where the sprue attachment points were located. The bulkhead was given a wash using a thinned burnt umber acrylic paint. Kudos to Trumpeter for the detail added to the cockpit. Using a good reference source and aftermarket PE one could ultimately detail out the cockpit. While this step is allowed to dry, we will move on Step 2.

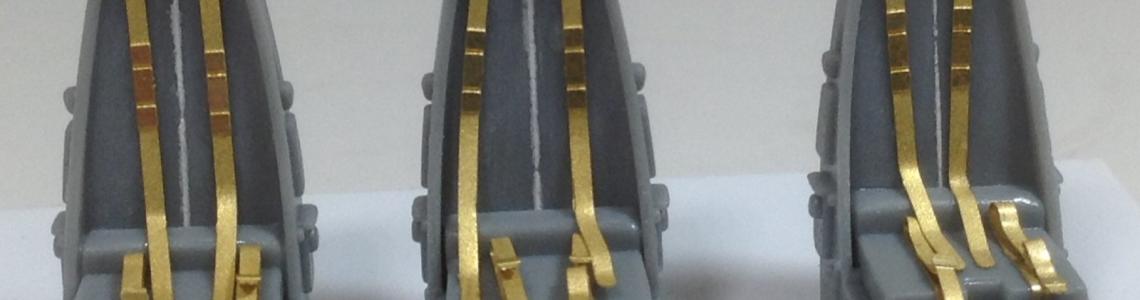

Step 2: Consist of making three seats containing PE for the lap belts and shoulder harnesses. Once parts J1 and J2 are glued together, a nasty seam runs down the middle, which needs to be filled with putty. The parts were carefully sanded to ensure a straight line, but putty still was needed. The seats were first sprayed with Vallejo Model Color 70.990 Light Grey. The seat cushion was hand painted with Vallejo Model Color 70.833 German Camo Bright Green with the seat belts hand painted using Vallejo Model Color 70.873 US Field Drab with highlights using Vallejo 71.074 Model Air Radome Tan. Then a thin wash using Vallejo Burnt Umber 70.941. Note: Reference pictures of the Captains seat has the headrest attached to the seat directly behind it. As noted earlier, this is strictly out of box with no corrections.

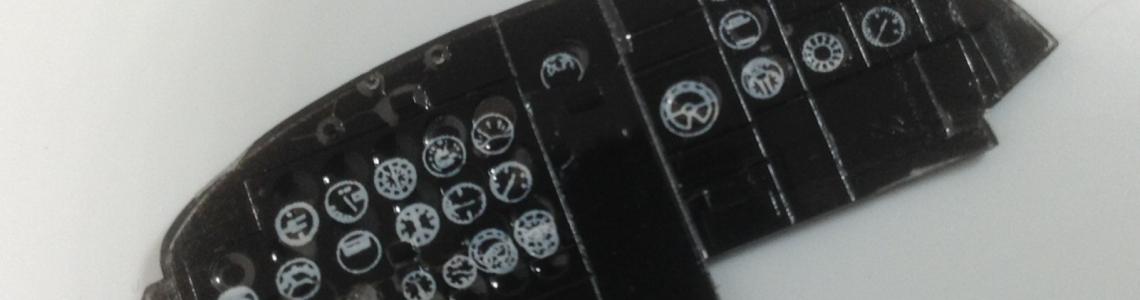

Step 3: As you construct the rest of the cockpit (with control surfaces, electronics and the 3 seats constructed in Step 2) you will find ejector pin release points that will need to be sanded and filled as these will show within the cockpit. Water plastic putty was used then sanded after drying. PE parts 17 & 49, PE parts 18, 47, 48 do not adjourn when gluing to right and left hand consoles. In order to make the adjournments possible, trimming would need to be done therefore some detail would be lost. The cockpit seats were painted before installing them into the fuselage. During this step, the instrument decal is applied. I used Solvaset Decal Setting Solution. I find this works great. However, when applying the decal, I found it did not line up with the gauge bezels. Instruments were painted as in Step 1. The PE parts PE 17, PE 49, PE 18, PE 48 and PE were imprinted so thin the builder has to be careful when applying paint in order to not lose the details. Unfortunately, due to the misalignment of the decal to the instrument bezels another alternative would be to paint the details and not use the decal.

Step 4: This step deals with the construction of the nose radar dome. Even though the radar will not show on the finished aircraft, construction will still be completed. No painting will be done. There were no problems during construction.

Step 5: Consist of the construction of the nose gear cabin. There were no problems here except some nasty seam lines on the wheel strut to clean up. The cabin was painted with Vallejo Model Color 70.842 Gloss White, which I found to be a good representation of Insignia White.

Steps 7-8: These steps deal with the construction of the electronic aggressor equipment bay which was upgraded from the A3D-2P strategic bomber. Again, when the fuselage is closed up nothing will be seen. Nothing here will be painted. The bulkhead (Part S20) does have several ejector pin release points that will need to be filled and sanded. Note some release points are depressed and some are protruding out. The one thing I noticed during the construction of the electronic equipment bay was the four seats (Parts K1 and K2) are placed on the floor in hexagonal holes but, there are no alignment pins attached to the bottom of the seats for placement. This didn’t present a problem but, was somewhat unusual. Also when the 2 seat halves were glued together there is a seam running down the center as in Step 3 with the Crew seats.

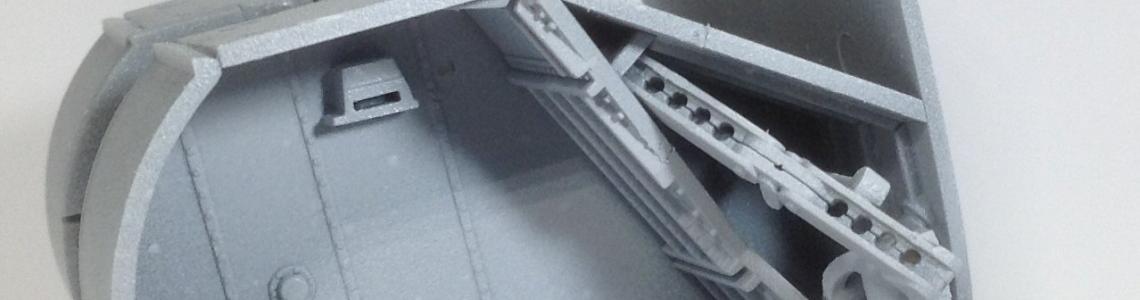

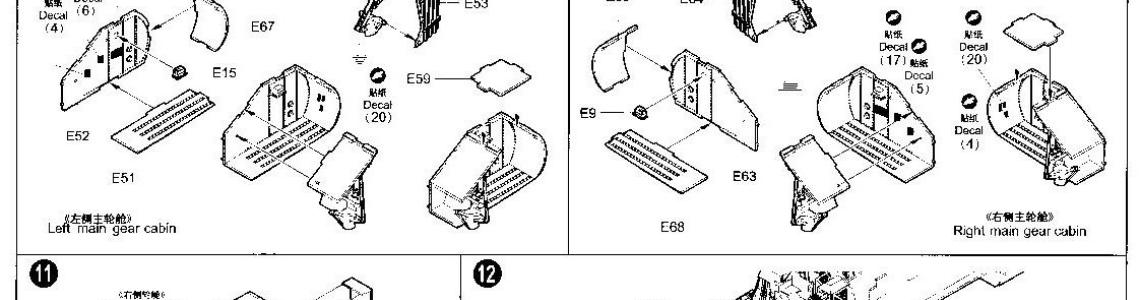

Steps 9 & 10: These steps consist of construction of the right and left main gear cabin. There are several subassemblies so care must be taken in orientation to ensure a proper fit. The inclusion of a finished picture of the gear cabin by Trumpeter would be helpful. During this phase of the construction I had a problem figuring out the instructions on building the main gear cabins. The pictures do not give enough information to ensure the parts are fitted correctly. This is where the internet comes in handy and any reference literature one has available. After some research, I was able to place the parts correctly in the cabin. Disclaimer: For those modelers who have built a variant of the Douglas A3 or built a plane that has the same landing gear configuration then this section should not be problem. However, if this is your first time constructing this type of landing gear a good knowledge of how the landing gear sits in the landing gear cabins will come in handy. The internet has several sites that depict a different view. I found that “Douglas A3D Skywarrior, Part One Design/Structures/Testing, Bruce Cunningham, 1988 Steve Ginter, pages 42-43” was an excellent resource. The instructions show the steps to build the parts but, unfortunately the angle of parts E53 and E64 glued to part E24/E17 and part E28/E33 are not relatively seen from the instructions. Here again a working knowledge would be most helpful. Whether it is my inexperience in building model aircraft or Trumpeter’s lack of detailed instructions, I did find that good reference material is essential in completing the main landing gear construction. What I ended up doing was attaching all three sides of the cabin before gluing in the landing gear in order to get the orientation of the strut in proper alignment. This in turn made painting the inside of the cabin a challenge. With careful airbrushing and hand painting, I was able to complete this step. Again the proper reference resources are essential. *I would recommend starting with the cabin bulkhead (G25) and Parts E51, E68 first before the rest of the parts of the main gear are added to ensure proper alignment and orientation of the gear strut. (See picture)

Step 11: Consist of gluing the right and left gear cabins to fuselage bulkhead Part G25). Here you will find some ejector pin release points which will need to be sanded off and filled. Other than the pesky pin release points, there were no problems.

Step 12: Here the builder glues the Nose Gear Cabin and radar to the cockpit. No problems here were noted by using the fuselage as a guide. Temporarily placing the fuselages together gives a quick check to ensure all the inside parts fit.

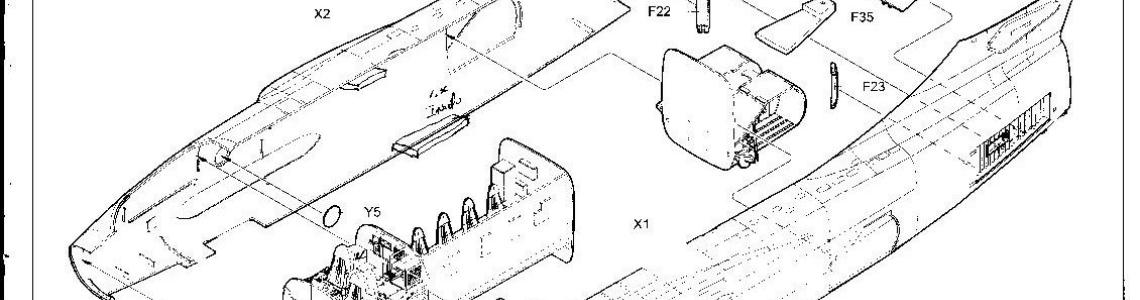

Step 13: Consist of joining the fuselage halves. Here one does not want to forget to glue in Parts Y5 and Y8 the bay windows. Future was added to the clear parts as I smeared white glue on one of them. With a little buffing and the addition of Future, the glue could not be seen. Due to the lack of additional locator points not molded in, plastic card stock was added to both halves of the fuselage to ensure a good fit and proper alignment. With this addition and a little sanding of the ECM bay , the main gear cabins joining the halves were completed. Hooray!!!!

Conclusion to Part 2

It truly is unfortunate that the radar and the ECM bay will not be seen when the fuselage is closed up. However, as modelers we will know they are there and what a great job we did. Even though there were a few issues, this kit should be reserved for the experienced modeler who definitely wants a challenge. This doesn’t mean that the basic to intermediate skill level modelers should not add this to their stash because, in building this kit they will find their skills will be put to the test. As I wrote before in this review good references are a must.

Now on to Part 3 which will include Steps 14-27 concluding with final painting and detailing out. Can’t wait.

Thanks to IPMS/USA, Trumpeter and Stevens International for allowing to review this aircraft kit.

Reviewer Bio

Phillip Cavender

Phil Cavender, IPMS/USA #50085, is a retired pharmacist from the Veterans Administration, having retired in 2011. While he explored model car building as a child, it wasn’t until 2015 that he rediscovered plastic scale modeling. His renewed interest emerged while researching his father’s military history, which led him to a local hobby shop. There, he met a former UK military tanker who reignited his passion for the hobby. After relocating to Myrtle Beach, Phil teamed up with six skilled modelers to co-found the Grand Strand Scale Modelers chapter of IPMS/USA. He now focuses on building armor models in scales from 1/35th to 1/16th.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews