Douglas DC-3

The Aircraft

The DC-3 was a development of the earlier DC-1 and -2, with each one getting a little larger and faster. The DC-1 was a result of a request by TWA for a Douglas airliner, as United had the production of the Boeing 247 sewed up and TWA needed a suitable airliner. The original aircraft after the DC-2 was the DST, Douglas Sleeper Transport, built for American Airlines to replace their Curtiss Condors. The DST first flew on December 17, 1935, the 32nd anniversary of the Wright Brothers first flight.

The huge advantage the DC-3 had was its greater speed and range. You could fly New York to LA in 17 hours, with 3 fuel stops. LA to New York was 15 hours due to prevailing winds. Previously, the practice was to fly passengers partway, put them on a train at sundown, and back on another plane at dawn.

Production of the DC-3 ended in 1942, and the C-47 took over the production facilities. There were 607 DC-3s built, but 16,079 were built of the DC-3’s variants – the C-47, Lisunov Li-2, and Nakajima L2D2 Tabby.

The Model

This is a smaller kit, but there are the normal two fuselage halves, horizontal stabilizers, a single-piece wing bottom, two wing tops, two-part nacelles (front and back) with detailed (for 1/144) engines and props. There are clear parts for the fuselage halves and a nice enough clear canopy.

There is no interior detail and no cockpit. I got the SAC metal landing gear for this kit as a review item, and it’s reviewed on this site.

Construction

There’s a little job to do before starting construction on this kit. You have to decide if you’re going to use the clear plastic parts or some other method of depicting the side windows. I decided to use Roden’s windows, so I had to paint the sides of the fuselage silver before I inserted those windows. I guess I could have waited and then scraped the paint off of each of those windows, but I’m pretty pragmatic about my inability to do that without pushing the windows inside the fuselage.

Once I had the fuselage halves together, I followed the instructions and put on the horizontal stabilizers. No real problem, but I did use some filler on these joints, as well as the seam on top of the fuselage.

I then tried to put the wing bottom on the fuselage halves. I say tried, because the fit was so tight I had to do some filing and scraping before the wing section would fit into the slot in the bottom of the fuselage. This is a pattern I found on this kit. The parts have no slop or wobble. Everything fits tight, and on many of the parts I had to do a little fiddling with a scraper or sanding stick before it finally went together. Great engineering here, and I really appreciate that Roden has such tight tolerances in their molds.

Then it was time to paint.

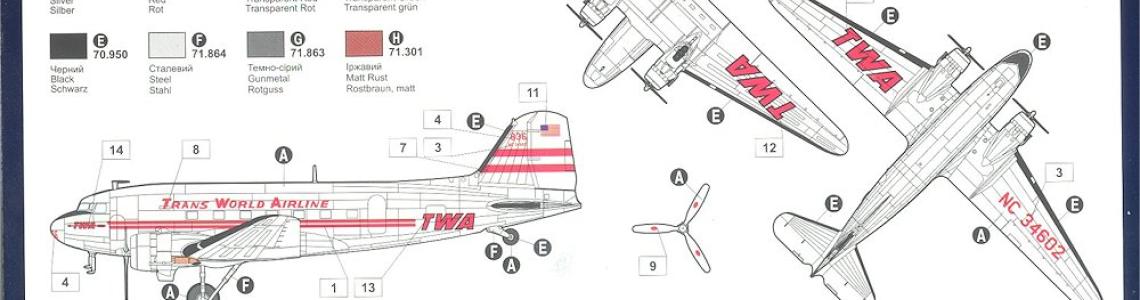

Painting

The color scheme on this plane is really simple. It’s natural metal overall, with black leading edges on the wings and vertical tail for de-icer boots. I had to mask the windows, but otherwise this was so simple. So now it’s time for markings.

Decals

I’m finding that quality of decals often is in direct proportion to the time it takes for the decal to come loose from the paper. Shorter time, better decal. These were quite good. I had a little trouble with the double line under the windows on the fuselage, but almost everything else was good. The two red stripes on the tail are too long to fit, but I put them on and then cut the excess off with a pair of fine scissors at the back of the rudder. Also, these lines aren’t angled to match the deicer boot on the tail. A #11 blade cut this line after the decal had set, and the piece of decal removed using Micro Set as a solvent. A quick application of Future made sure the decals stayed on.

Final Construction

I always leave the landing gear and small parts off until I’ve finished decals. That way I’m not having to reinstall small stuff, or looking on the floor for detached small parts. The engines and nacelles went together with the nice tight fit. I knew immediately if I didn’t remove the sprue attachment enough, since the parts wouldn’t go together. I was pleased with how well the propellers fit onto the front of the engines, although I had to hit each one with a #11 blade to get them to fit.

The landing gear was from SAC, and it fit.

I put on the canopy, antennas, and pitot, and all of a sudden the project was finished.

Overall Evaluation

Recommended. This model goes together nicely, with no sloppy fit. It requires a little extra work to get some of the nice tight parts to fit together, but that’s far superior to gaps which have to be filled with large amounts of filler.

Thanks to MMD/Squadron for providing the great kit, and to IPMS/USA for letting me build it.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews