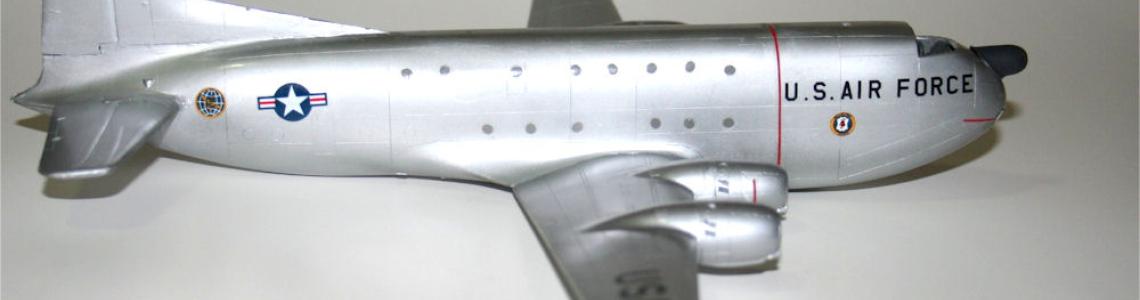

Douglas C-124C Globemaster II

The Aircraft

The C-124 Globemaster II was the ultimate piston-powered cargo aircraft. The C-124 entered service in 1950, just in time for the Korean War. Based on the C-74 Globemaster, which first flew just after VJ day, the C-124 used the same wing as the C-74, but the fuselage was enlarged so the C-124 could carry 10 tons more cargo than the C-74.

Based on lessons learned in the Berlin Airlift, the 124 featured clamshell nose doors which allowed drive-in loading of vehicles. Until the advent of the turboprop C-133 in 1957, the C-124 was the only US transport capable of carrying tanks and large trucks.

The C-124 remained in service with the ANG until 1974, the last ones retiring from the 165th Airlift Wing of the Georgia ANG.

The Model

This is a release of the C-124C, following Roden’s earlier C-124A. The big visual differences between the A and C are that the C had a “thimble” weather radome on the nose and the addition of heating units on the wingtips which provided de-icing and cabin heat.

There are only two clear parts, a navigator’s dome and the cockpit. The windows are indicated by decals. The model is molded in flash-free gray plastic, with no warped wings or fuselage parts noted.

Construction

The construction is pretty straightforward, except for step 3. Roden throws in a little surprise here. They call for 30 grams of weight in the nose. Those who have read my reviews before know that a US 5-cent coin (nickel) weighs 5 grams. So that’s SIX nickels in the nose to get the model to sit on its nose gear. I added a penny to the stack, making it 32 grams. Those are copper birdshot, not BBs.

There aren’t any locator pins and holes in the parts, but it’s not difficult to get the parts to align, as the fit is pretty good. I was gratified to find that Tamiya Extra Thin Cement works fine on the plastic in this kit. So does Tenax, Testors Liquid, and CA, both liquid and gel.

Step 9 was misleading. It shows the cowling/engine assemblies with 4X part 10F. Unfortunately, you only get two of these parts. It turns out that these are the firewalls between the inner engines and the landing gear wells, and they aren’t needed on the outboard engines. The fit was a little suspect on all 4 cowls, but the engines hold things in place, and the seams can be dealt with without large doses of putty.

I waited until after the wing top and bottom halves were assembled before cutting off the wingtips. That way, if I made an error, it was shared equally between both parts. I found that the new wingtip heaters had some fit issues with the wingtips, requiring some putty work.

I also found it difficult to get the vertical stabilizer to mate cleanly with the fuselage top. I used red putty for the visual impact in the photo. Green or white putty would have worked just as well, but would have been harder to see in a graphic. The horizontal stabilizers also had no guidance, just flat surfaces on the fuselage sides that they glued to. The fuselage sides have stub parts to guide and support the wings. There are some unused parts in the sprues which look suspiciously like supports which were supposed to go through the fuselage to support the wings, but so far the wings have held fine without these supports.

There are a number of small parts which glue to the bottom of the fuselage and wings, such as vents, scoops and flap hinges. I departed from my usual practice of leaving these off until I finished the decals because I wanted to paint them on the aircraft, giving a better looking finish. I only ripped two of the ten hinges off during decaling.

Paint and Decals

The paint scheme for this era is super easy – aluminum overall. I used Model Master Aluminum Metalizer for the entire plane. As soon as it was dry, I put on the Future coat, as the aluminum has a tendency to rub off during handling.

The decals had some pleasant surprises. Everything was in register, the colors were what I expected, and the decals came off the sheet cleanly and could be worked to get into position. The passenger/cargo bay windows are indicated on the fuselage with little engraved circles, and a decal goes in each of these. Roden did well by me, supplying 18 extra window decals, just in case.

Decals finished, another coat of Future keeps the decals protected and in place.

Final Construction

Now, it’s time for me to put those two hinges I broke off back on, install the landing gear and gear doors, and put the props on. The parts for the main gear went together pretty well, but I broke the retracting arm for the nose gear while attempting to cut it off the sprue. I fixed this with a piece of wire, but the SAC landing gear looks like a good investment for this kit.

I installed the clear parts, which fit OK, with only a small gap at the rear of the main canopy.

You have to drill the holes for the props, but there’s a nice little indentation to start the drill in the correct spot, and it went well. I used a #61 hobby drill. I was pleased with how well the propellers fit into the holes I drilled in the front of the engines.

Overall Evaluation

Recommended. This is a fine kit, especially for the experienced modeler. There are things which are not simple to assemble, but the resulting model is a great-looking and impressive aircraft.

Thanks to Squadron and IPMS USA for the chance to review this kit.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews