D9R Armored Bulldozer

Ever since I was a young lad, and would pass construction and road works sites while out driving or walking with my Father, I have loved bulldozers. Big, yellow and Caterpillar! Yet whenever I went to try and build a model of one, I always struck out. The only kit I could ever find of a Caterpillar product in injection plastic was a 1/25th scale kit, which was either too expensive for me as a young hobbyist, or the wrong scale once I got a job but moved on to focus on modeling military subjects in 1/35th scale. This year, however, Meng Models from China, a relatively new player in the model kit industry, has hit the ground running and provided the 1/35th scale military modeler with an amazingly detailed injection model of the mighty Caterpillar D9R armored bulldozer. Read on!

What’s In The Box

- 17 Sprues worth of parts in tan injection molded plastic

- 5 Sprues worth of parts in a dark gray/blackish plastic

- 2 Sprues in clear plastic (one tinted blue, one untinted)

- A length of rubberized “hose”

- 1 fret of photo etched brass parts

- 1 sheet of decals

- 1 A4 sized instruction booklet, 20 pages

- 1 glossy color sheet covering painting and markings

The first thing to note about this kit for anyone familiar with Meng’s previous kits is that they have dispensed with the green plastic which feels very oily (excessive mold release?). This kit’s main sprues are in tan (and minus the oily feel), which for me is a huge plus. The detail on the parts is much easier to see in tan, if nothing else. All the parts themselves are extremely well molded, loaded down with great detail, and with one exception free of sink marks or flash. There are a number of prominent ejector marks, which initially had me very worried that this was going to be “putty central”, but as I went forward with the build, I realized Meng had placed these ejector marks where they would not be seen once the kit was fully built. So kudos to Meng for this!

While loaded down with detailed parts, this kit is very straight forward to build. The parts engineering is very good, and I had no issues during any of the construction sequences. Portraying a massive bulldozer as it does, the kit is also lacking in teeny tiny parts, which as my eyesight starts to cause me issues, is a great PLUS in a kit as far as I am concerned! The kit also has “working” features, or at least “positionable” ones, to wit the front dozer blade, and the rear ripper assembly. Make sure you carefully study the instruction sequences, and avoid getting glue where you shouldn’t; so that you get these two major units in the position you want them in.

The driver cab area of the kit is very well detailed (Assembly Sequences 7 through 18). Examining the instructions carefully, I soon figured out that the cab would need to be built as a series of subassemblies, then painted, before final assembly of the various smaller “units”, as once the roof is attached, the modeler won’t be able to access the cab interior. The various windows and doors were assembled and painted MINUS the clear parts. I then painted the exterior of the cab unit; weathered it, all prior to installing the clear windows, which need for the most part to be installed from the inside of the cab. Once all this was successfully done, I attached the pre-painted and pre-weathered cab roof.

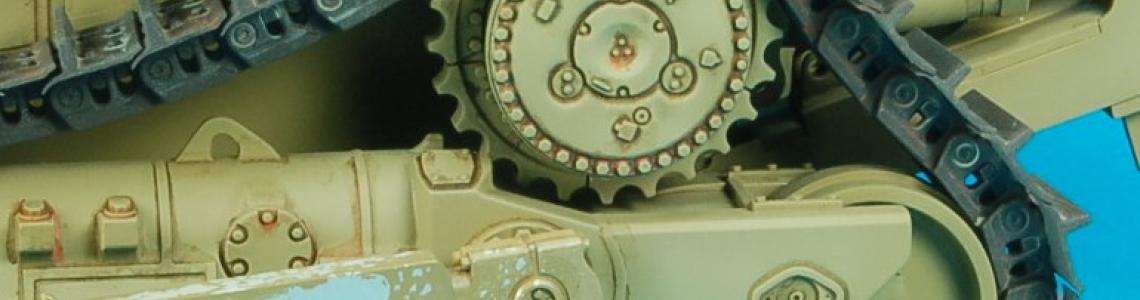

Assembly Sequences 24 through 26 have the modeler building up the road wheels, track drive sprocket, and tracks. The latter number 43 links per side, with each link consisting of three parts. If one is careful, and sparing with the glue, these tracks are fully articulated. Do not glue the two track drive sprockets (Parts A10/11/12 plus poly cap) onto the model until after the model is almost fully assembled and painted, as this allows you to paint the tracks separately prior to installing them on the model.

The one area where I did run into a small sink mark issue was in Section 34 of the instructions. When gluing parts E21/E22 and E24/E23, there was a slight depression where these parts are joined together. Nothing major, and as I say, the only sink mark issue I ran into on the entire kit.

Make sure when you are planning your assembly to check out all the little headlamps and tail lamps. Carefully remove the clear lenses for these lights, and test fit to make sure which way they are to be installed, and to see if you need to remove any excess plastic for a good fit. Remember to factor in the thickness of the primer/paint in your calculations, as you will most likely wish to install these lenses after everything has been painted.

Meng’s painting instructions turned out to be a bit of a pain, as they only listed paints from the Vallejo acrylic range. These are not the most common of paints in the USA to locate, and of course cater only to those who use acrylics, which I don’t. Nor do many of my modeling friends. Thankfully as mentioned below I was able to find an Israeli Defense Forces mix using my favorite Tamiya range of acrylic lacquers via the internet.

I decided to try to use the “hair spray” technique for the very first time on this model. Studying local bulldozers around town as well as military ones on the internet indicated that the front of the bulldozer blade soon has its paint worn off, down to the bare metal. So I primed the kit’s front blade unit, and applied a couple of coats of my favorite silver paint, Floquil Old Silver. Once this was thoroughly dried, and having bought a cheap aerosol can of hair spray, I gave the blade a few light coats of the clear liquid. I left the hairspray to dry for about a half hour, helped along by a blow dryer, and then painted the blade with my chosen base coat of Israeli Defense Forces “Sand/Hemp”. Checking on the internet, I found a suitable mix utilizing the Tamiya range: 1 Part Tamiya XF-49 Khaki to 2 Parts XF-20 Medium Gray. To lighten this for “fading”, add some Tamiya XF-57 Buff. I then helped this along the drying sequence with a hair dryer again. I let the paint sit for about a half hour again. While drying, I then got an old towel, an old, soft bristled tooth brush, plus a couple of other old paint brushes, and a wooden tooth pick. With some warm water, I then began to work small areas of the dozer blade, “scrubbing” the moistened areas with either the toothbrush or the old paint brushes. After a short time, the paint began to flake off and I worked on various spots until I was satisfied with the “chipping” effect. I also used a tooth pick to make long scratches in the paint as well. I was VERY happy with the results for my first attempt at this technique.

I then let everything thoroughly cure for a couple of days, before moving on to the decals.

The kit comes with three color and markings options:

- Option A: a US Marine Corps. Vehicle stationed in Iraq, 2004

- Option B: an Israeli Defense Force vehicle, 603rd Combat Engineers Battalion, July 2006 Lebanon War

- Option C: IDF Combat Engineers School Bahalat”z, August 2008 (my choice)

I applied the decals in my standard fashion: a light application of Tamiya X20 Gloss Clear, followed by the decals, which consist mainly of some large vehicle numbers, and a few stencils here and there. All were well printed, and went onto the (flat) surfaces with ease. After being allowed to thoroughly dry, the decaled areas had a couple of additional light coats of Gloss Clear applied (make sure you carefully mask the windows of the model), before the entire model was airbrushed with a sealing coat of Testors Dullcote. I then applied a dark brown “wash” to the entire model to help pick out the details, while the tracks received a couple of different “wash” treatments, “dust” and “rust”.

One final paint note: depending on which photos you look at, IDF D9R bulldozers either have red paint appearing on various spots on the vehicle (grab handles etc), or they don’t. I decided that all that red on a military machine looked weird, so left off the red paint. I also felt that if you went to the trouble of painting a vehicle in a camouflage color, why then ruin the effect by applying red?

I thoroughly enjoyed building, painting and decaling this excellent kit. Despite its huge size, construction provided me with no headaches whatsoever following a couple of careful reads of the instructions to figure out how best to approach the assembly. I ended up building the model in a series of sub assemblies which were assembled, painted and weathered separately, before being brought together to create the whole. I can heartily recommend this kit to anyone with a few armor kits under their belt. It has provided me many nights of very enjoyable modeling. My thanks to Meng Model for providing IPMS USA with this review sample.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews