British Heavy Assault Tank A-39 Tortoise

The relatively new Chinese company, Meng, has recently released the first-ever rendition of the British A-39 Tortoise, a behemoth ostensibly created to join battle with the German super-heavy tanks being designed at the close of World War II. The mind boggles at the specter of a platoon of (Tortai?) engaging a gaggle of MAUS monsters on the plains of Europe. Of the six vehicles completed, however, only one was sent across the channel for field testing, but it never entered combat.

The Kit

My first thought upon opening the box was: This is a big tank. Not a lot of parts, but what’s there is significant. Much has been said about the delicate nature of some of the parts that represent electric lines and cables. Well, they weren’t kidding. The first thing I did when I opened the box was to snip out the frame surrounding these parts carefully (they are all together) and place that sprue section in an envelope to protect it. I have no doubt that the weight of a single un-bagged sprue lying up against these parts would have broken the delicate pieces.

At the other end of the spectrum, the individual track links look absolutely HUGE. The Tortoise links proved to be a breeze to clean and assemble. There is a single length of white nylon string that almost gets lost between the bagged sprues (it is not included in a bag) – this is supposed to be used for the tow cables but ended up in the trash can (more on that later). Many of the remaining pieces look very similar to each other, but are not. I can’t begin to say how many times I attached something upside down and/or backwards because I overlooked the smallest of differences. Go slow.

The contents of the box include:

- 1 upper and lower hull packaged together in a bag

- 6 sprues in dark green plastic packaged separately

- 3 sprues in dark brown plastic for the 144 individual links packaged in a single bag

- 1 25-inch piece of thin, white string

- 1 14-page instruction booklet sheet with 23 steps and a 4-view color diagram

The Instructions

This is the second Meng kit I’ve had the pleasure to build, the first being the VsKfz 617 Minenraűmer. While the soft green plastic used in this kit is different, the high-quality of the instruction booklet is the same. Meng really puts the extra effort into presentation and accuracy, which can make the build a real joy and keeps me coming back for more.

Things to consider before starting:

Should you clean and assemble what you can’t see?

More than half the parts in the kit make up the bogies and individual track links, yet most of this detail is hidden by the side skirts. If you decide (like I did) that you just want to build what you can see on the finished model, then ignore the differences in the “Suspension Systems A and B” – they are both the same. More on this later. Don’t bother cleaning any of the return rollers and related detail, and you will use only about 76 links (out of 144).

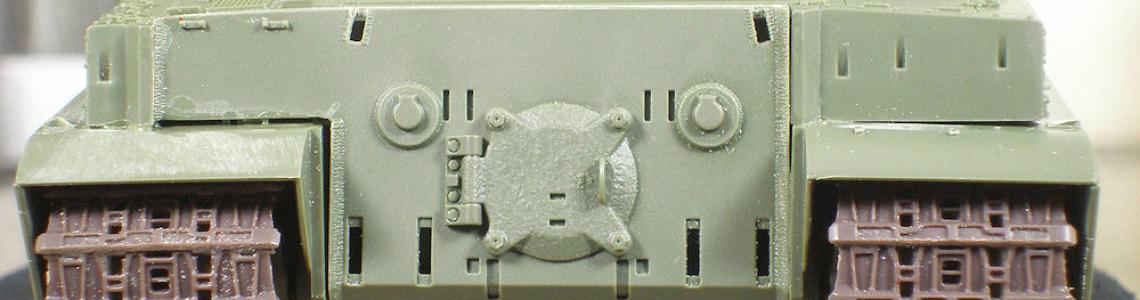

Possible bad fit of the main superstructure.

Before you begin, take out the main upper and lower hulls and try to fit them together along the curving line of plastic molded into the lower hull made for this purpose. If it fits, ignore the remainder of this paragraph and the images showing the ugly gaps below. In my review copy, the main upper hull would not fit over the guide, but I did not realize this until I was well into the project. I made the mistake of trying to force it with glue and clamps, only to find out that by doing so I had bowed the lower chassis in such a way as to prevent the rear hull plate from fitting later on. This, of course, caused all sorts of other problems. If you find that the upper hull in your kit does not fit perfectly, I suggest you complete Steps Eight and Nine and part D35 in Step Eleven first. Then, carefully scrape and sand off the molded-on guide on the lower hull, and glue the upper and lower hulls together. After that, you can go back to Step One and start the kit proper.

Leave that barrel off!

I had to handle this model a lot over the course of the build so I am glad I left the long barrel off the vehicle until the very end. It really gets out there!

The Build

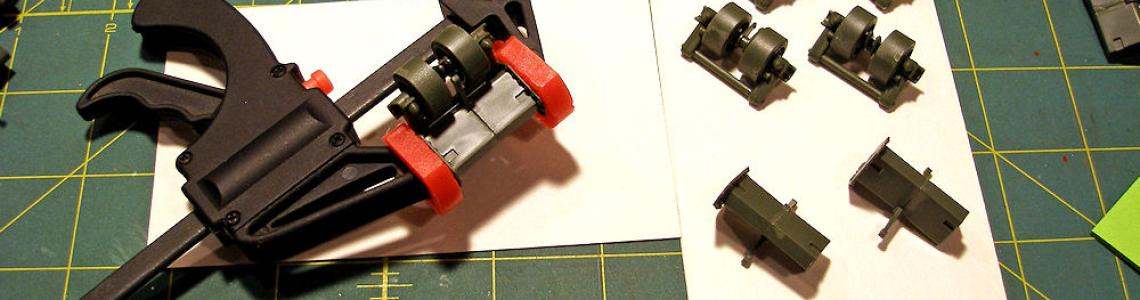

Assembling the Bogies and Wheels

Looking across the internet, I noticed that there are a variety a ways to assemble the bogies for the Meng Tortoise, none of which are per the instructions included with the kit. Perhaps this is due the fiddly nature of the design – there are many built-in features of the kit that allow parts to be movable and such. Or perhaps it is due to the fact that most of the undercarriage is not visible on the final product, and therefore can be bypassed if desired.

Whatever the case, the design here is a little finicky, but I commend Meng for making the best of a complex engineering problem to begin with. I ended up using a little from each of the several approaches I found. By the time I got to the third bogie I had come up with what I feel is the best way to get from here to there:

- Review the two Bogie Assembly images below and follow along in the instructions.

- Glue part A10 to parts A12 and let this dry thoroughly. There are sixteen of these assemblies.

- Glue part A2 to parts A7 and A5, fitting these three parts around the above assembly, leaving the above assembly free-turning. You will need to pay careful attention to the alignment here as there are no detents or other design features to guarantee the parts line up. These assemblies must dry thoroughly before continuing.

- Glue parts B28 together, trapping the two swing arms (Parts A3) between them. The swing arms must be able to swing freely. Since there is no difference between Suspension System A and B if you are not including the (hidden) return rollers, do the same with parts B29 and B30, again trapping parts A3 between them.

- Glue (one) part A1 to one end of the assemblies you created in Step 3, above. Let everything cure. From here on you will be working with one bogie at a time until all eight are finished.

- Glue the second part A1 to the other end of the assemblies you created in Step 3, above. Before this dries too much…

- Hold the assembly firmly between your index finger and thumb, and, paying attention to the angle that the swing arms need to be in when you are done, slip the wheel assemblies you made in Step 2 into place. The bumper nubs need to be pointed upwards when in place. A quote from a scene in the movie Finding Nemo comes to mind here. "Think about what you have to do, and do it."

- When all looks right, rotate the axles around so that the swing arms are lined up with where they need to be attached, and, using your thumb, simply click them into place. Nice.

- Add a drop or two of Tamiya liquid cement to the bottoms of each side plates to hold everything in place. This is essential because…

- The wheels actually have a little travel in them, even after attaching the swing arms. To prevent the bogies from being uneven along the track, you need to decide if you want the Tortoise to 'stand tall' or 'hunker down' when completed. Note that I say that with tongue firmly in cheek here; we’re talking perhaps an eighth of an inch. But it will make a difference. I chose the former, so before everything firmed up. I pulled the wheels down as far as they would go so they would all line up once the glue dried.

I have included a picture below (from the manufacturer) that shows a fully-detailed bogie assembly. If you decide to go that route, attach the return rollers and their accompanying detail now, after everything else has dried.

Once all eight bogies are dry, attach them to the main lower hull. If you have left off the return rollers, attach the bogies in any order you wish – without them there is no difference between the two Suspension Systems called out in the instructions. Otherwise, study the diagram at the bottom of page five to see which bogies go where.

The Track

My last build was a German Maultier with ridiculously small individual Magic-Track links. By comparison, the individual links for the Tortoise are embarrassingly HUGE. But they are beautifully detailed inside and out and fit together very well. The only bad thing I have to say about the track is: they are so big that if one slips out of your fingers while lining up a run, the sheer weight of the thing will scatter anything it hits – but this is certainly no fault of Meng’s.

You are provided with 144 links total, which gives you 72 per side if you assemble full runs. I assembled only the visible track, using 38 links per side and still had a few extra. There is some debate on the internet about which way the track is laid on the bogies. I simply used the box-top illustration as my guide and moved on.

Attaching the Side Skirts

Once the track was dry, I looked at attaching the side skirts and ran into the first real design issue with the kit. There are no less than seven connection points of different shapes and sizes, all out of sight, that have to line up perfectly in order to attach each side skirt. The thin edge along the top also requires a close fit to produce the fine seam line there. Since the clearances are so close, and the plastic is so soft, I simply decided to shave off all of the connection points with a scalpel, using a new blade. This resulted in a perfect fit.

With the undercarriage, track, and side skirts attached, the hefty bulk of this model started to become apparent. I hope it never gets dropped!

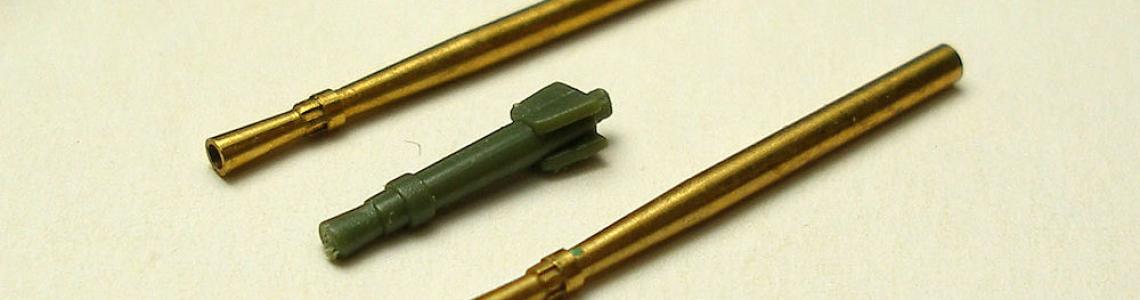

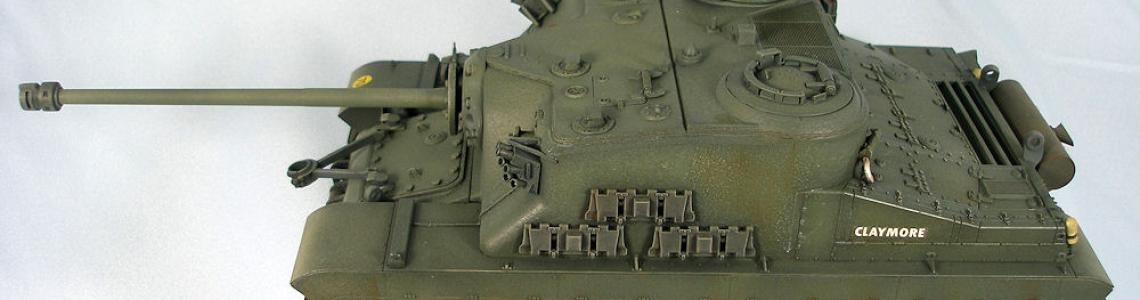

Smoke Dischargers and Machine Guns

The three smoke dischargers look beautiful when finished, but will take a little care getting there. Each of the 18 tubes is molded separately and wobbles in all directions, so I glued two at a time to each discharger and waited for each set to dry before doing the next two.

There are three BESA Mk 3 machine guns on the Tortoise; two in a small revolving turret up on top, and one on the left-hand side of the upper hull. I used the kit part for the latter, but chose to purchase the brass replacements from LionMarc for the turret, which is really a little model in itself. With the smoke discharger added on the side, the completed machine gun turret looks like something more suited for a Mech or Gundam Warrior figure model. Very cool.

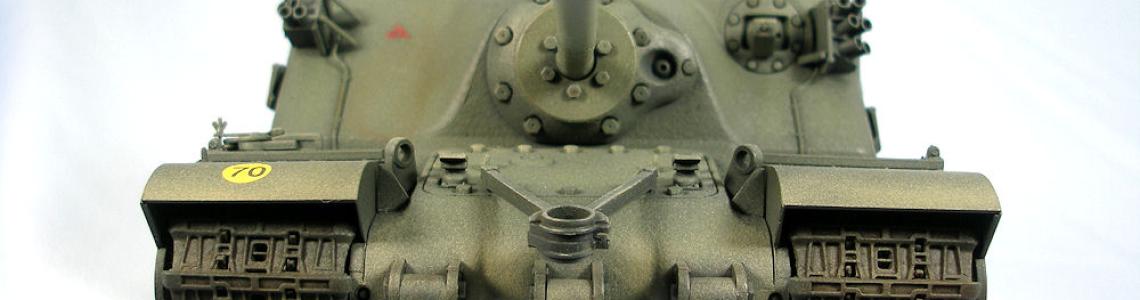

Towing Hooks

There are five robust-looking tow hooks, three on the front and two in back. If there was ever an opportunity for me to get something upside down and/or backwards, it was here. This is because no matter which way you assemble the half-dozen parts for each hook, they all fit – ergo, they can (and will) all fit wrong. I strongly suggest you assemble the hooks using the following steps:

Towing Hook A

- Clip and clean parts B37 and B38.

- Hold them up next to each other to make sure one isn’t flipped upside down.

- Glue them to the lower hull where they should go according to the directions, making note of the specific side(s) showing detail vs. no detail.

- After they are dry, push part B11 through the holes and through part B39. Make sure the detail for part B39 is facing outward.

- Push part B10 into the hole in front and secure the whole assembly with some liquid glue.

Repeat for the (three) Towing Hook B’s, using the appropriate parts for those hooks.

Tow Cables

The very last step I tackled was the tow cable assembly, stored on the starboard side of the lower hull. It’s funny; I worried about the bogies, the super-thin electric lines, the intricate smoke discharges…but what I ended up spending the most time with, and having the most frustration with, were the tow cables. I build German armor, and I’ve had my share of tow cable problems, but none came close to what I encountered with the Tortoise. I think Meng really blew it here.

- First – Meng should have molded these cables in plastic. There are so many delicate and beautifully-molded plastic parts in this kit, many of which might have been done in photo etch by other companies. Why Meng chose to use a thread-and-plastic cable-end approach here is a mystery.

- Second – the nylon thread provided is both grossly out of scale and easily frays when manipulated.

- Third – the plastic cable ends are in scale, but are far too small to accept any kind of material, much less string, and that’s assuming the modeler can successfully hollow out the tiny ends in the first place.

- Fourth – the placement of the cable bundle requires that the cable itself be drawn relatively tight between the two attachment points. This requires that the four cable sections be cut exactly right – which is very difficult, all things considered.

I started by replacing the nylon string included in the kit with a tighter, twisted cotton string. I then carefully carved out the underside of each plastic double-cable-end so that it resembled an upside-down U-shape when done. I then stuffed the two string cables into the cavity and used CA glue to fasten them. Carefully measuring four pieces of string, I repeated the step above three more times. Unfortunately, when fitted with the fiddly hardware that fixes the tow cables to and around the hull, two of the four cables proved just a bit too long.

Consequently, I applied white glue to the cables to stiffen them and then cut the entire cable assembly into three pieces and glued these to the hull separately, attempting to hide the gaps behind the two cable supports. Not perfect, but good enough.

I attached the smoke dischargers (which went on like a charm) and carried the beast over to the paint booth.

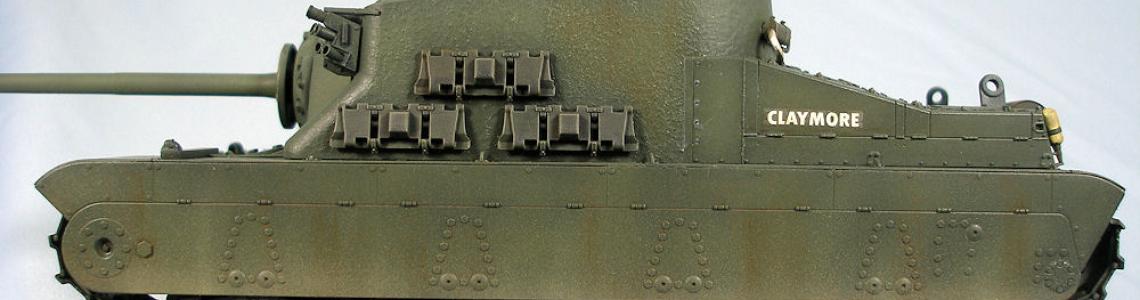

Painting and Finish

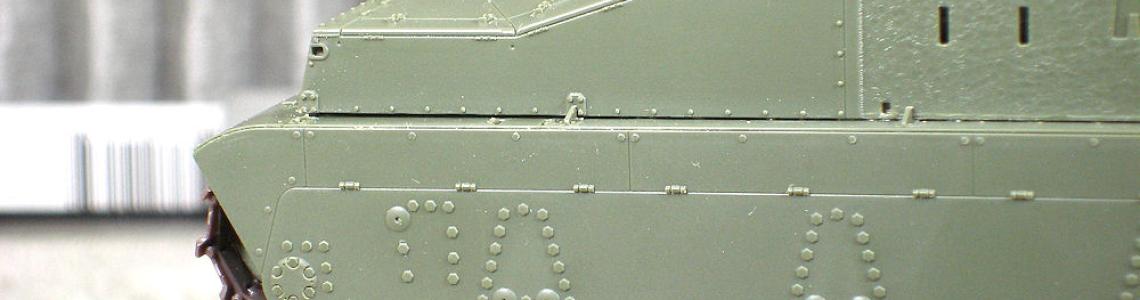

The A-39 can be painted any color, as long as it is green, so that’s what I chose. Post-war British armor is a shade or two darker than American armor, so I settled on a black-green that I could lighten-up with post-shading and weathering.

I started by airbrushing a primer coat of Gunze Mr. Surfacer 1200 over the entire surface to cover the oils and glue spots and to prepare it for the subsequent finish. I then airbrushed the entire vehicle Tamiya NATO Black to provide the dark shadow that I wanted in all the nooks and crannies. I then gave the entire model a coat of Humbrol 75, leaving the black to show through along the edges and recesses. I followed this with a post-shading coat of Humbrol 75 cut with a little Humbrol 103, which is a pale yellow, working from the center of the panels outward, to lighten up the dark green color underneath.

To add some character to an otherwise dull finish, I hand-brushed Future in all the appropriate places and applied some spare decals from my stash (the kit does not come with markings). Looking at reference photos of late/post-war British armor, I hand-painted the red triangle stamp on the front upper hull Tamiya X7 Red, the fire extinguishers Vallejo Model Color Buff, and the braided air-cleaner hose Tamiya XF-16 Flat Aluminum. I followed this by adding a filter to the exhaust manifold using several applications of Mig Abt060 Light Rust Brown, and used Paynes Gray for the smoke dischargers and extra track. Both of these colors were heavily thinned with Mona Lisa White Spirit.

Once dry, I shot the whole vehicle with Future to seal the decals and prepare the surface for a wash and a little streaking. I let the Future dry for two days and then gave the vehicle a pin wash using Mig Shadow Brown 015 oils (aka Raw Umber). To give the flat upper surfaces and the side skirts more depth, I added dots of Mig Wash Brown, Mig Light Rust Brown, and Mig Light Mud here and there, and rubbed those down with an old cotton sock damp with Mona Lisa. I swirled the same colors in a circular motion on the top of the vehicle and rubbed them out as well to lighten that area up a little. I then added some oil stains using Tensocrom Oil. While the oil paints were drying, I brought out the detail by carefully dry-brushing all the protruding bits with Model Master Afrika DunkelGrau RAL 7027 1942, an enamel. I usually use oils for dry-brushing, but I like using this Model Master color after looking at some of James Wechsler’s great green-armor weathering examples.

I followed this with a road-dusting coat of Vallejo Model Air Light Brown, and then shot the whole vehicle with Vallejo Flat Varnish to kill any remaining shine. I finished the vehicle with a light dusting of various Mig pigments, light earth tones for the body and wheels, dark rust and black for the track, and gun metal to the edges (applied with my finger) to give everything a look of heavy steel.

I finished by attaching the barrel and adding a jerry can from my spare-parts box to the empty tray at the back of the upper hull, securing it using a small piece of lead foil.

Conclusion

Building the big A-39 was both a pleasure and a challenge.

On the plus side; Meng’s superb engineering provides a better (plastic) alternative to the copious photo-etch you find in kits from some other manufacturers. Some of their assemblies are as fun (and challenging) as it gets. The small gun turret up on top; the smoke dischargers, the bogies and wheels, the five devilish towing hooks – all are a lot of fun to figure out and finish.

Truth be told, I have clumsy modeling sessions and I have ‘on’ sessions – it seemed like during this build I had far more of the former for some reason. Nearly every problem I encountered, however, proved to be self-inflicted. Meng ‘s instructions are superb and the assembly sequence is generally on target. I guess you just have to be ‘on’ to build this kit right.

On the negative side; I had some fit problems (that might have been due my sample copy) and a frustrating experience with the tow cables. Those issues aside, however, I think this was a great kit to build. The Tortoise helped me become a better modeler and there’s nothing wrong with that.

I recommend this kit for average to experienced modelers. Go slow, pay attention to the instructions, and use the suggestions included above. You will be rewarded with a real eye-catcher.

I would like to thank Meng and Steven’s International for providing this kit for review, and IPMS USA for giving me the opportunity to build it.

Reviewer Bio

Eric Christianson

Eric Christianson is a father to two boys (Reed and Dean), the President of the Seattle Chapter of IPMS, and a long-time Little League umpire. He is also a devoted husband and companion to a wonderful woman named Jackie who enthusiastically supports his passions. Recently retired as a programmer, his home office has been scratch-built into ‘a perfect model room’. Modeling since he was a boy, Eric mostly builds armor these days, but still dabbles in 1/32nd aircraft and other types of models from time to time. He also enjoys presenting seminars on weathering and technique at local shows. Many of Eric’s kit reviews can be found on the IPMS USA website.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews