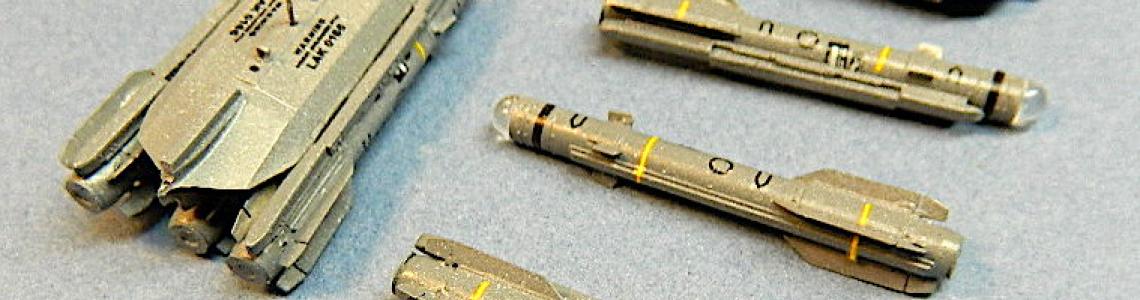

Brimstone w/AGML III Rack

History and Background (thanks to WikiPedia)

Brimstone is an air-launched ground attack missile developed by MBDA for Britain's Royal Air Force. It was originally intended for "fire and forget" use against mass formations of enemy armour, using a millimetric wave (mmW) active radar homing seeker to ensure accuracy even against moving targets. Experience in Afghanistan led to the addition of laser guidance in the dual-mode Brimstone missile, allowing a "spotter" to pick out specific targets when friendly forces or civilians were in the area. The tandem shaped charge warhead is much more effective against modern tanks than older similar weapons such as the AGM-65G Maverick, while the small blast area minimises collateral damage. Three Brimstones are carried on a launcher that occupies a single weapon station, allowing a single aircraft to carry many missiles.

After a protracted development programme, single-mode or "millimetric" Brimstone entered service with RAF Tornado aircraft in 2005, and the dual-mode variant in 2008. The latter has been extensively used in Afganistan and Libya. An improved Brimstone 2 was expected to enter service in October 2012, but problems with the new warhead from TDW and the ROXEL rocket motor put back the planned date to November 2015. MBDA is working on the targeting of swarms of small boats under the name Sea Spear. The RAF intend to fit Brimstone to their Eurofighter Typhoons, and planned to integrate it with their Harriers until the latter were withdrawn from service in 2011. MBDA is studying the use of Brimstone on ships, attack helicopters, UAVs, and from surface launchers. However, it will not be integrated on the Lockheed Martin f-35 Lightning II. The United States, France and India have expressed interest in buying Brimstone for their aircraft, but Saudi Arabia is the only export customer as of 2015. The cost per missile has been quoted as $263,000 each in 2015.

In November 2016, the German Air Force announced as part of a closer cooperation between Germany and the UK to procure Brimstone 2 dual mode missiles for their fleet of Eurofighter aircraft from 2019 on. Germany decided against their own missile development as the Brimstone 2 missile already meets 90% of the demanded requirements.

Contents Description

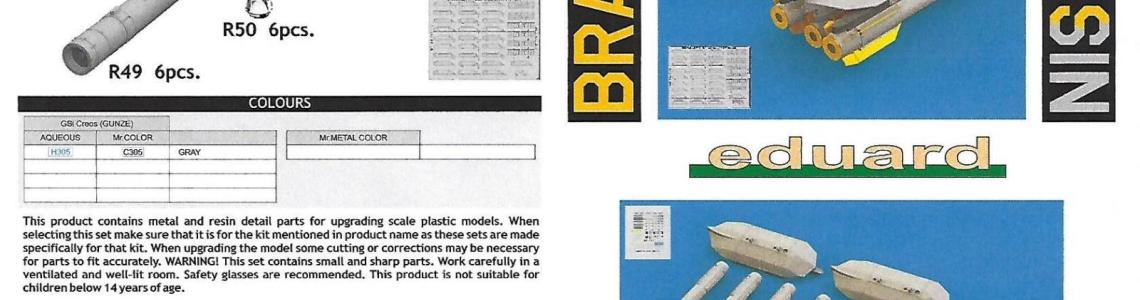

The resin parts include six missile bodies, six clear resin seeker heads, four rails and two AGML racks. A small fret of PE includes parts for the fins and rocket nozzles. Lastly there is a small sheet of decals for the missile markings and stencils.

Instructions

The instructions are provided on a small, four-page fold out. While reviewing the instructions in an effort to familiarize myself with the many parts and assembly I realized there were no instructions for the decal placement. I went to the Eduard website and obtained the full-size instructions that not only included information on decal placement but also how the missiles fit the racks.

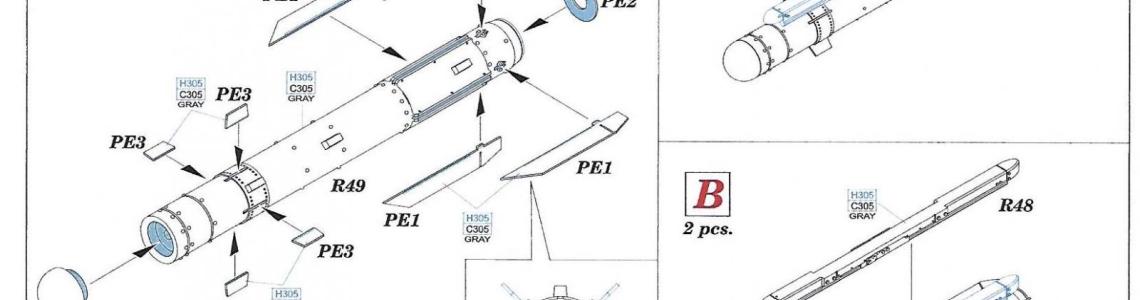

The exploded view of the missile assembly identifies all the resin and PE parts by number and notes the paint color to be used (Gunze H305/C305). The AGML rack is also painted the same color.

Assembly/Construction

I washed the resin parts in warm water with a drop of liquid detergent, rinsed them with warm water and set everything aside to thoroughly dry before starting the assembly. I used a fine razor saw to remove the missiles from the casting blocks and a number 11 hobby knife blade to remove the rails. The AGML racks have an elaborate casting block that requires some care and study of the instructions before the excess resin can be removed. Study twice, cut once! The PE fret was cleaned with alcohol.

Two missile body exhaust ends are cast on a common block and careful removal with a micro saw is required. The clear resin seeker heads are mounted three to a casting block. The heads will be fitted to the recess in the missile body front end, while the PE exhaust ring in glued to the end cut from the casting block.

The four rails are identified as parts R47 and R48 and are slightly different in detail. Each rail has three small rectangular recesses that will fit over three small raised tabs on the missile bodies. Four of the missiles must be fitted with rails, while the two center line missile are fitted directly to the AGML rack centerline. It seemed to make sense to me to fit the rails to the missiles before the PE parts were to be fitted. I left the rails on the casting block while fitting the rails to the missile bodies for ease of handling. I applied a small dab of gel super glue to the recesses and fitted the rails to the bodies. One of the rails was slightly warped and would not align the recess and the raised nubs. I straightened the rail after an immersion on hot water.

Once the rails were glued to the missiles, and the glue had set up overnight I used a micro saw to separate the rails from the casting blocks. A test fit of the rails with the AGML revealed the rails were handed. A recess in one side or other of the rails aligned with a raised, linear element on the AGML that fit together like puzzle pieces. I added brass wire pins to the top surface of the AGML racks to fit to the model later. The brass pins not only allow for a secure mounting in the finishing step but also provides something to hold the part/assembly for painting.

Installing the fins is the most challenging part of the build. Each missile is assembled from four smallforward fins and four aft main fins, a exhaust nozzle ring, and a clear resin seeker head. The smaller forward fins are to be fitted and glued into very tiny, shallow slots in the missile body, while the main fins are fitted into double-side raised recesses. All this points to challenging fit and delicate assembly. There are surplus fins for both sizes which will allow for possible loss or damage. I planned to assemble the missile bodies and rails first before fitting the fins in place. I used slow setting super glue gel to fix the fins to the resin bodies. The rear fins slide into the raised recess and the small tab on the bottom of the fin fits into a recess in the body. This is a surprising good fit, but it is just hard to see what goes where. Care is required to get the forward fins perpendicular to the missile body before the glue sets up.

Painting and Decals

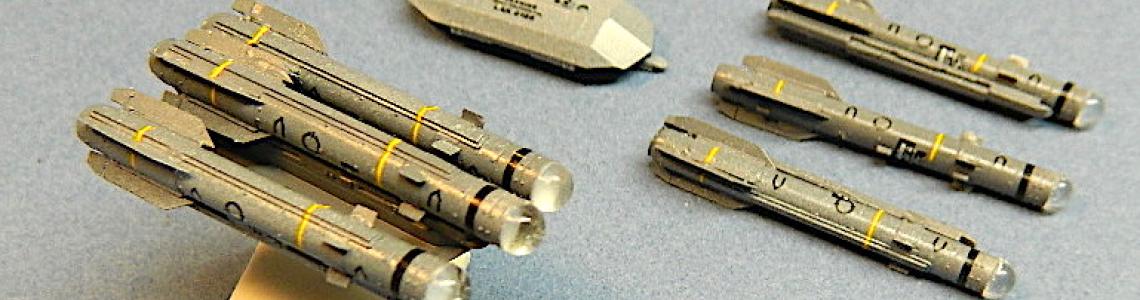

First, the missiles and the AGML would be painted separately. Everything was primed with Tamiya fine white primer, decanted and thinned with Mr. Color self-leveling thinner. After a 24 hour cure time thin applications of Mr. Color H305 were applied and again allowed to cure for 24 hours. A gloss finish was applied using Model Master Gloss and that was set aside for 48 hours.

The decals were immersed in warm water for a few seconds and set aside to loosen. These decals were the most uncooperative and stubborn decals I have ever used. It seemed like several minutes were required before the decals would separate from the backer sheet. I noticed the backer sheet did not absorb water in a very uniform manner and as a result the individual decals did not fully loosen for quite some time. But each one did eventually release and could be placed on the missile bodies. The decals were applied using MicroSet and MicroSol. When everything was dry and set a final finish coat of Model Master Satin finish was applied.

Clear Resin Parts

I used a micro saw to remove each clear resin seeker head. Although the resin heads appear to have a short plug that would fit into the front hollow in the missile I decided to cut the heads off directly behind the heads in the event the plug was be too large for the missile body. The back side of each head was given a light sanding to eliminate the saw marks. The heads were then glued in place.

Conclusion

I thought it a bit unusual that an aftermarket product for the Brimstone missile would be offered when its use is currently limited to the RAF and Royal Saudi Air Force Tornado aircraft. I found images showing four AGML with three missile each fitted to RAF Tornados. Looking ahead there may be other nations interested in adding the weapon to their inventory. That opens the door to modelers interested in adding this missile system to their builds.

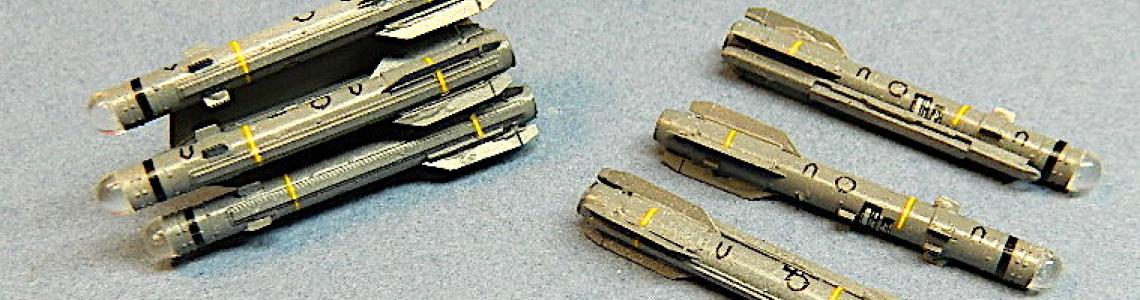

These missiles are not an easy assembly due to the nature of the many small PE parts and the delicate nature of the resin parts, but with careful study of the instructions, care in the assembly, good eye sight, and patience a very nice replica of a modern weapons system can be created. The missing instruction pages may have been a fluke in this instance, but the Eduard web site came to the rescue. The decals could have been more cooperative, but in the end they did work.

I wish to offer my thanks to Eduard and IPMS/USA for the opportunity to review and build this product. It was challenging and fun, and the results are quite satisfying. These missiles and racks will be a stunning addition to any RAF or Saudi Tornado.

Recommended for those up to the challenge.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews