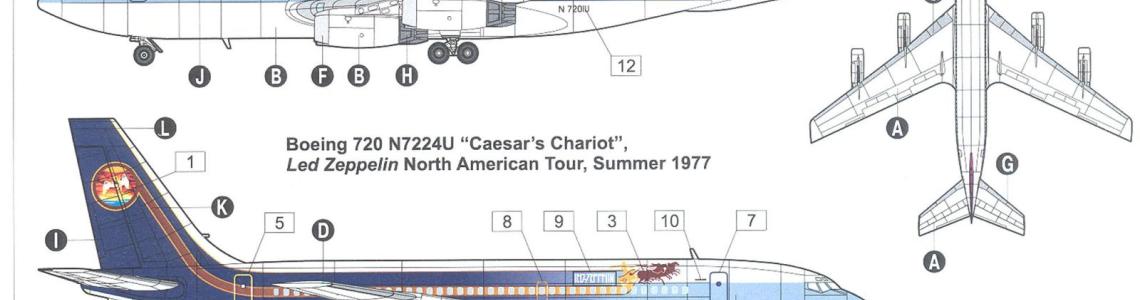

Boeing 720 “Caesar’s Chariot”

The Aircraft

The Boeing 720 was a direct development of the highly successful 707. The 720 had a shorter fuselage and was narrower, making it more cost effective for airlines on the shorter runs. 720s were profitable for Boeing because the development work had all been done with the 707. There were two basic versions of the 720, 720A and 720B. The A had P & W JT-3C turbojet engines, the B had JT-3D turbofans. Many As were upgraded to Bs through changing the engines. 720s were built from 1958 to 1967.

The 720 in this kit was a 720B N7224U, owned by Caesar’s Palace in Las Vegas Nevada. The aircraft was called “Caesar’s Chariot”. It was leased to the rock group Led Zeppelin for their 1977 North American concert tour. The plane had a special paint job, with Zeppelin’s “Swan Song” album logo on the tail.

There are 3 other 720s in the Roden Music Series, one used by Deep Purple in 1973, Elton John’s 1975 tour, both being the “Starship” 720 N7201U, and the Bee Gees 1979 tour which used N7224U.

The Model

The kit is what’ you’d expect from a 21st Century airliner kit, with recessed panel lines, clear parts for all the windows and cockpit, complete landing gear, and the correct engines for the aircraft. I was amused to find our old friend flash on one of the fuselage halves, which took almost a full minute to remove. Otherwise the molding was clean, the parts had no warp or bad fit, and the instructions include a sprue layout to make things easier to find.

Construction

The instructions for this kit are different from the usual procedure. The steps are:

- Assemble the engines

- Assemble the landing gear

- Assemble the wing top and bottom, then put the main gear and engines on the wing assembly

- Put the windows in the fuselage halves

- Assemble the fuselage halves with the nose gear, add the wing assemblies, add the horizontal stabilizers and put in the cockpit glass.

I just don’t do it that way. I find that if I put the small parts like engines and landing gear on too early, I wind up having to do repairs due to handling. Instead I painted the fuselage halves white, painted the wings white, and painted the leading edges of the wings and tail and the bottom of the fuselage silver. I then assembled the fuselage and wings. I also painted the horizontal stabilizers white with silver leading edges, but didn’t put them on until later. I also installed the cockpit clear part and cleaned up the joint here.

Painting

Having looked at the kit decals and the paint job, I decided that there was no way I was going to be able to do this scheme justice. The dark blue on the tail continues down the fuselage sides as a pair of blue stripes above and below the dark brown stripe on the tail. The blue fades to a pale blue as it gets to the wing, and continues to the cockpit area. The dark brown stripe with gold edges goes from the tail along the fuselage side, fading to yellow at the wing, ending with the Chariot logo. The decal sheet doesn’t have the blue stripe, and the brown stripe ends even with the stabilizers, leaving the builder to paint a brown stripe with golden edges in a curve at the tail and down the windows while changing the color to yellow, and the edges morph to brown.

I found a set of aftermarket decals for a Boeing 720B flown by Aer Lingus, the Irish airline. I bought them.

The rest of the painting was just touch up of the top and bottom of the fuselage and the wing roots.

Final Construction

After putting the Aer Lingus decals on, I finished up by installing the engines on the wing. I had some trouble here, as the pins and holes were pretty small, and I had to use a lot of care to get the engine mounts to line up with the equally small dimples in the wing bottom while keeping them at right angles to the wing bottom.

The landing gear was very good, a solid mount which probably shouldn’t need aftermarket metal to be strong enough to hold the plane. I’m a little concerned about the main gear doors, as they come as one piece, and have to be folded twice for “gear down”. One of the folds is just a 90 degree bend, and there’s nothing to prevent the stress of folding to eventually cause the part to separate, losing the door part. I could be wrong here. I hope so.

Overall Evaluation

Recommended. The plastic part is very good. I had no unusual problems with parts fit. The markings part is probably too difficult for a lot of modelers, but the aftermarket decals make this a project to show off at the next chapter meeting.

Thanks to MMD-Squadron and Roden for the review kit and IPMS/USA for the chance to build it.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews