Bf-110D/E

Before I get onto reviewing this model, I would like to give a little back ground information about this aircraft.

The Messerschmitt Bf110 served in the Luftwaffe throughout WWII. Even though it wasn’t very popular with the German pilots at that time it was developed into a successful night fighter, in spite of its poor handling characteristics. Later on it was realized what a great night fighter it really was and soon became the backbone of the German Luftwaffe night fighter wing of WWII.Some of these units were formed as early as 1940.

In August/September 1943, Bf110 aircraft shot down over 2700 RAF bombers. Also, in just one night, without fighter cover, these aircraft destroyed at least 120 RAF bombers. The Bf110D was a long-range heavy fighter and/or fighter-bomber, while the improved and up-armored Bf110E was designed primarily as a fighter-bomber.

Dragon has already released a Bf110C in its 1/32 scale Wing Tech series, but they took it one step further and followed it up with the Bf110D/E which is a “2-in-1” kit configured as a night fighter only. Modelers thus have the choice of building a 1/32-scale Bf110D or E aircraft equipped for night flying. The appearance of these night fighters is quite different from the Bf110C, because of the radar antenna fitted on Bf110D's nose. In this kit the modeler has a choice of using the antenna photo-etched parts or the standard plastic parts that are already molded to exact detail. Special parts are further provided for the Bf110E, including a new nose and rear wheels, a newly tooled machine gun and nose antenna and so much more. Modelers can also choose to have a camera-equipped Bf110E aircraft. Whichever version of the aircraft you choose to build, you can be assured of the highest quality and level of detail in Dragon’s Wing Tech Series. I am choosing the Bf110E to build as there are newly tooled parts that are awesome and I already have two Bf110s earmarked to build as a 110C & a 110D in 1/48 scale with all aftermarket parts bought and planned for.

When this box arrived I was amazed at the size of it. It was huge for only one model. As I took off the top cover and saw all those sprues, along with the level of detail, I realized that this kit deserved a lot of attention. With that in mind I resolved myself to build it very close to OOB to try to give it a fairer review. I did however add wires and drilled out lightning holes and also scratch built small details, but nothing that alters the assembly in any way. These scratch details certainly do not have to be followed to build this kit into a great replica. I decided that I would follow the instructions in the order that Dragon designated and not to deviate in any way

There are a few issues I want to mention just to get them out of the way so that they won’t have to be mentioned again. The first of these issues are the small nubs that are on every part. These need to be cut off very carefully then sanded smooth. These nubs are a pain in the neck but are necessary to push the sprue out of the mold without producing sinkholes and marks that can ruin the details. Secondly, there are also molded seams on most parts which need minor sanding. All of these issues can be very time consuming but necessary which is a small price to pay for this great detail. I have also assembled some parts out of order which are simple to assemble and may have gaps to deal with after the assembly. These parts, such as bombs, stabilizers, rudders, etc can be glued together then sanded and gaps filled if necessary. This will not affect the order of assembly, as these parts will be glued in their place in order of assembly.

I am not going to list all the details and newly tooled items as there is way too much to list. These listed details and their pictures can be seen on Dragon’s website.

COCKPIT AND RADIO COMPARTMENT:

Steps 1 and 2 incorporated the full cockpit and radio compartment. All parts of the same color of the same assembly were assembled then painted to minimize glue marks. I did, however, use the Eduard Zoom kit for the interior and according to the Eduard instructions, the original instrument panel had to be sanded smooth in order to join Eduard’s instrument panel to the original part. I chose to trace and cut out a sheet of plastic so as not to ruin a beautifully detailed instrument panel. Eduard’s instrument panels are painted perfect and no dry brushing could ever come out so good. I also used RB Productions seat belts to also enhance the cockpit. This was very tedious but very worth it. These were the only two after market items that were used in this assembly which really didn’t take away from the construction as a whole. Before the front seat was installed, I cut and placed a small fitted piece of black construction paper onto the back of the frame just behind the seat that the radios are glued to (Step #2, assembly-B) in order to hide the opening which would have been seen in the back of part E9.

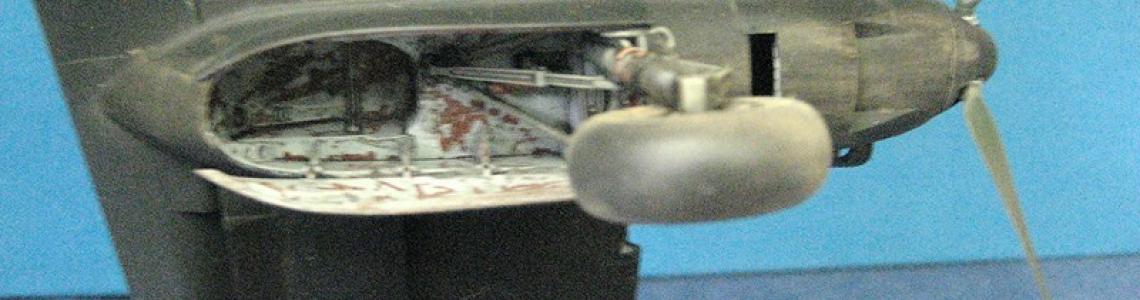

Everything fitted perfectly and needed no persuasion to make the parts fit. The interior painting was done according to Dragons instructions, which I found for the night fighters to be correct. I wouldn’t waste too much time with the cannons (part #G4) under the cockpit assembly because after placing the cockpit in the fuselage, most of it can’t be seen anyway. Also in Step 1, assembly –C, the extra ammo cases (parts D48 & D65) aren’t necessary if you choose to cover them with the fuselage panel (part A4) as shown in Step #3. I painted them anyway just in case I decided to show them. It would be hard to paint them as an afterthought. I also drilled out the lightning holes found mostly on part E8, D20 and around E15. Also in Step #2 the arrow shows assembly “F” being glued to the rear right corner of the bulkhead which is holding the ammo. If you would just look below on the page, a better diagram is shown as to how assembly “F” should fit. Since I am doing the –E version, in Step #3, I only chose to glue three machine guns to part A7 and paint only the barrels since after fitting that assembly into the nose, the only thing that can be seen is the very tips of the guns. The oxygen bottles couldn’t be seen either, so I left them out. It made sense to me to use these bottles as spares for another time. I didn’t like the look of the metal tips on the barrels either, so I left those off also. I didn’t glue the “glass” at this time since I find it easier to mask first and then glue the glass when I’m ready to paint the outside of the aircraft. At this point I chose to weather the cockpit and add some colored wires to add effect and realism to the cockpit. You also may notice that the weathering is done to a very high degree because after these planes came back from a mission, they were fueled up, repaired quickly and sent out again with very little time to clean the cockpit. Aside from a wash, I also used the “Hair Spray” method to bring out the rust that formed in the cockpit and on the window frames.

The method done for this is in its simplest form. Paint the base color with an enamel rust color. Let it dry for a short while then spray hairspray over the painted part and let dry for approximately an hour or so. When dry, paint the top color that you choose with acrylic type paint and allow to dry for a few hours. Even overnight is fine, but not necessary. Then take a pin and scratch small light lines where you want the rust to show through and saturate the area with plain water. With a hard bristled brush, rub the area and you’ll see how the water “melts” the dried hairspray and the top color comes off without disturbing the rust paint underneath. This sort of gives a 3-D effect where the rust seems to come through the top coat as opposed to it looking like it’s painted on.

FUSELAGE, ENGINE, WHEEL STRUT & WHEEL BAY ASSEMBLIES:

Right here is where I joined the fuselage halves and attached the nose assembly. These parts fitted together so well and so straight that there was almost no need for sanding at all. However there is no such thing as an invisible seam, so a very small amount of Zap-A-Gap was placed on the fuselage seam, top and bottom. The seam where the nose fits onto the fuselage can be left alone because there is a visible panel seam on the real thing. Some fuselage lines had to be rescribed after the sanding of the Zap-A-Gap was done. This was minimized by placing tape about 1/8” away from either side of the fuselage seam. The line was put back with a new #11 Exacto blade and pretty much pressed down to create the small panel line which was missing. Just go slow and easy and it should come out perfect. The glass and all the small pieces will be glued later on. The strut assembly went together well and I added some black wire to represent brake lines and made small round clamps to fit around the strut and wire to look like they’re holding the brake lines to the strut. I made the clamps by pressing solder wire flat and also the solder conforms to the strut and wire very easy, then it was glued with ca glue and left to dry. All the strut parts were painted prior to the wire assembly. The motor was also pre-painted and assembled and all the parts fitted perfect. The wheel bay assembly also went together well but there is no way of knowing how parts A6 & A5 should be fitted as the instructions are not very clear as to how it should fit. I waited until the end of the assembly and then just fitted it the back corner of the bay. You’ll see that it could only go in one way and that it’s on a slant. I also wrestled a little with the fitting of the struts to the wheel bay but in the end they did end up fitting perfectly. Again, take your time. I painted the wheel bays and the inside of the wheel bay covers a light blue color (RLM-76) and again the hair spray method was used where I wanted a touch of rust to show to keep the weathering uniform. It came out really great. The panels surrounding the engine were assembled and the exhausts were left off until much later. I did spray them a rust color so that later I can paint over them with burnt exhaust to use over the hair spray. I should point out that I left off part J30 (hose line) off the engine because it didn’t fit well when the panels are closed. If you choose to leave the panels open to display the engine, then the hose can and should be left on. Don’t worry about the seam lines on the panels – they should be there. Just make sure they are even. The wheels are easy. Paint the centers and tires individually and assemble. I used dirty black for the tires.

The wing and the engine assembly to the wing are very straight forward, but take your time with the parts and their fittings because it is very easy to get them mixed up. Also think about the weathering and to where the layer of rust should be painted to again conform to the existing weathering. Since I was building the Bf110E, I needed to follow the lower right side of the instructions. In showing the small insert for the rear landing gear, I believe that parts F26 &F26 were left out as in the left side insert. Without those little spacers the tail wheel will wiggle” on its axle. So to alleviate that, I used them. They are a necessary part of the installation, not to mention the detail they add .On my kit the tail wheel sprue is marked as an “L” but is called out on the instructions as a “K” part number.

Another thing to keep in mind is that there are two versions of the rear horizontal/vertical assembly, so be sure you pick the correct one according to your version. All the small parts that are needed to be attached to the wings and stabilizers were added last because I know I will knock them off and possibly lose them to the invisible “worm hole” in my carpet.

FINAL ASSEMBLY: WINGS, SMALL PARTS, DECALS & WEATHERING:

>Once again, I am building the –E version, so I will be following the bottom half of the page which contains Step-12. After studying the diagram for a moment, I realized that the tail wheel assembly cannot be installed to the stabilizer assembly until that assembly has been fitted to the fuselage, and then the tail wheel can be inserted into the hole. I am still holding off gluing the small parts on so that they won’t have to be masked or broken while painting the fuselage. These parts include the wheels, antennas, ladder, exhausts and propellers. At this point I masked the canopy and temporarily assembled its pieces together with blu-tak and secured them to a piece of cardboard. I painted the first coat on the canopy a light rust to conform to the interior. The top coat will be applied with the same color as the fuselage. In that way the inside would appear to have a rusty look and the outside will be the color of the aircraft.

Even though the decals provided were perfect in every way, I chose to use the markings of Wolfgang Falk’s personal aircraft. He was known as the “Happy Falcon” and was given the title the “Father of the Night Fighters” by his men. Falck was selected by German Luftwaffe High Command to create the Nachtjagd, a night fighter force, due to his fine leadership, knowledge of military facts and being a very capable fighter pilot. His Bf 110E-1 was the first to be painted all black for night duties. The decals were purchased from EagleCal, (EC#45), and they too were also flawless in every way.

Since I was going to paint the aircraft all black, I wanted to finish it with a worn and used look, showing that it had seen lots of action, but yet still strong enough to withstand even more punishment. I happened to find the perfect color for this situation. It’s an enamel paint called “Grimy Black” which is one of the Railroad Colors from Floquil. Since the aircraft had a band of yellow around the rear of the fuselage, I painted that first and when dried, it was masked off. Next the cockpit and wheel bays were stuffed with cotton and masked off for the final painting. I did apply an overall light coat of gray to the fuselage to check for flaws and corrected whatever flaws were found. After a few light coats of Grimy Black were applied, I painted the Propeller Blades a dark green (RLM-70). When dried, I glued the props to the engines along with gluing the canopy to the fuselage. After removing all of the masking from the cockpit and the canopy, I glued open the necessary canopy panels.

Now it was time to prepare for the decals. I covered the canopy with wet Kleenex so as not to get the clear paints on the glass. I gave the aircraft two light coats of clear gloss enamel for a smooth surface to apply the decals. I wanted the decals to have a weathered look as well. So I placed the decals in their correct positions and pressed out the large bubbles, but left the creases. When the decals dried, I took some very fine grit (220) sandpaper and sanded the decals very lightly until the creases were sanded off revealing some paint from under the decal. I then applied Micro-Sol to pull them toward the paint. I was real pleased with this process because it gave the effect of the decals looking like they were weathered by the wind, but not enough to erase the decal completely. This wasn’t done to that degree on all the decals, just on the group markings because too much would take away the realism. The other decals were given a very light sanding to give them a very mild fading effect. I then glued on all the remaining small parts. I hollowed out the exhausts and installed them to the engines. A very tedious job, but well worth it.

Now it was time for weathering. I found it very hard to find the right color wash for the panel lines and recesses. Everything I tried looked so artificial that I almost decided to not do it at all. The wheel bays looked good with the normal black wash, but it just wasn’t right for the “skin”. I then had this idea of using diluted MIG Pigments. I placed a small amount of “Russian Earth” (P034), which is like a dark brown/black mixture, and mixed it with distilled water and brushed it in all the panel lines, top and bottom, including the lines covered by the decals. After this dried, approx 5 minutes, I wiped it off gently perpendicular to the panel lines with a moist cloth and/or Q-Tip. What was left in the panel lines was the perfect shade I needed for this shadowing effect. It was pure luck, but I will be using this method again. I then sprayed on a few light coats of Model Master Flat Acrylic which blended everything together perfectly and lastly I applied the antennas using stretched sprue. I did scratch build a small microphone which hangs over the open window to the right front of the cockpit.

In conclusion, the whole kit was a pleasure to put together. Everything fit well and it built into a perfect rendition of the Bf 110-E. The only negatives I found were those little pesky nubs on every part and the fact that there were a lot of mold seams. Although these came off easily enough, it still was time consuming and a big “PITA”. This is a big aircraft and finding a place for display could be a problem, especially if you build a base or a diorama. Although the price is kind of up there, you do get a lot of plastic for your money.

I would highly recommend this kit to all who have moderate skills and better. I would even consider recommending this kit to newcomers who have had at least a few good kits under their belt. This kit goes together that well. The instructions can be misleading at times but nothing here is brain surgery. The complete understanding of the steps and diagrams with test fitting should bring the builder nothing that can’t be resolved.

I would like to thank Dragon with their Warbird Series and IPMS/USA for the opportunity to review this kit.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews