Badger Renegade Krome Airbrush

From time to time, one gets the opportunity to review a finely crafted and indispensable item such as an airbrush. Badger recently provided a copy of the “Renegade Krome,” along with an assortment of Badger acrylic paint to IPMS/USA, and it, indeed, is an excellent airbrush.

First, there is a treasure trove of information on the Badger website about the Krome, including an informative and excellent video. To view this video, please visit https://www.youtube.com/watch?v=2JBaqBK1kU4&feature=youtu.be

I recommend that you check out this video before your initial use of the Krome, as it will answer many questions about the use of the rear adjustment knob which controls paint flow, plus breaking down the airbrush to clean it, and reassembly after cleaning. The video narration addresses the modifications made by Badger between the Krome and earlier versions of the Renegade. These modifications have resulted in smoother “action” on all moving and adjustable parts.

The documentation that comes with the airbrush highlights what are called the “Notable Renegade Airbrush Series Features.” Let’s take a look at these features and see if they, indeed, are accurate.

Claim # 1 “Tensionsense” ultra responsive trigger tension control system.

During my testing procedures, I found the trigger to be smooth and easily manipulated in regard to controlling the flow of air and paint. The video mentioned above addresses this point and offers a brief explanation as to how Badger built such fine control into the trigger system. The end result is that the trigger is comfortable, precise, and easily controlled. Claim # 1 is verified.

Claim # 2 “Stopset” accu-precision trigger setting mode

In plain language this means that there is an adjustable knob on the back end of the airbrush that “limits” the back and forth movement of the needle, regardless of how much pressure one applies to the trigger. This adjustable knob, in essence, controls how much paint is coming out of the gun. Clearly, if the knob isn’t engineered to control very small amounts of paint, then it’s rather worthless. In the case of the Krome, during my first few minutes of familiarization and use, I was able to apply a consistent and extremely thin line of paint. I found that the adjustment action was smooth and easily controlled, all with slight turns of the adjustment knob. “Accu-precision trigger setting mode” is an accurate description! Claim # 2 is verified.

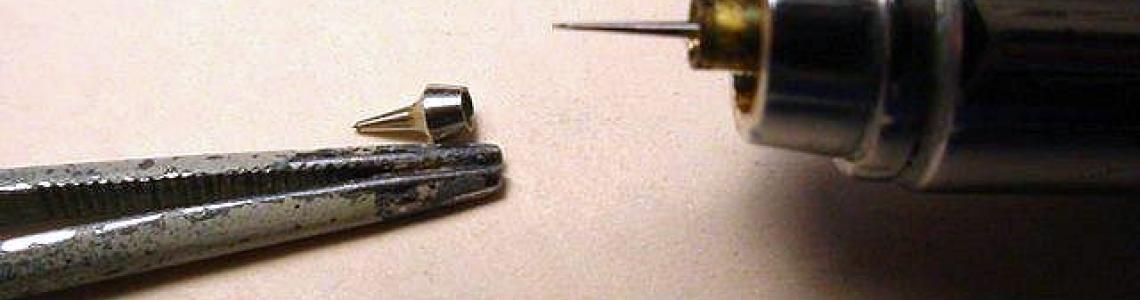

Claim # 3 “Exact taper fit, non-thread, micro-precise paint tips”

This description refers to part # R-003 Ultra Fine Tip, (for the Spirit, Velocity, Velocity Jet, and the Krome) and # R-004 Fine Tip (Rage). In other airbrushes manufactured by other companies, this part is threaded, but in the Krome it is a non-threaded part. The fact that it is non-threaded means that it is much easier to remove and clean than a threaded part, and that there are no threads for paint to seep into. The down-side is that once you remove the tip’s Hold Down Ring, part # RK-001, the tip can fall away, never to be seen again. It is T.I.N.Y.!

I like the fact that it is not threaded and can easily accommodate the need to be cautious when removing the Hold Down Ring. Just be aware of the fact that when removing the Hold Down Ring, the tip will be loose and unattached to the body of the airbrush by threading. Claim # 3 is verified.

Claim # 4 “PointPerfect polished needle micrology”

The needle is, of course, one of the most important parts in a double-action airbrush. Upon removing the airbrush from the packaging, and upon removing the needle from the airbrush, I found it to be, for lack of a better term, in perfect condition. The tip was in mint condition and well protected by the rubber nose guard (used when storing the airbrush) and the two protective flanges of the spray regulator. Of course, it is incumbent upon the user to protect the needle and that precious tip when cleaning the airbrush and especially when reassembling the airbrush. Any stress applied to the tip with deform it and cause damage, so caution is the name of the game for the Krome as it is for every other airbrush with a similar design. Claim # 4 is verified.

Claim # 5 “Smartcenter” nozzle technology with patented “guide and hold” assembly design ensuring perfect paint tip centering for tighter line production.

The patent referred to is patent # 5,421,518, which reads, “An airbrush which comprises a front body through which air and paint are directed is provided. A head, having a tube known as a post, is removably attached to the front body. A paint tip and a regulator, removably attached to the head, are also provided. The regulator comprises a detachable holding ring and a regulating tip. The paint tip is secured to the head by the holding ring when the paint tip is placed within the post and the holding ring is attached to the head. The regulating tip can be detached from the airbrush while the paint tip remains secured by the holding ring. The head, paint tip and regulator, comprising a crown, are interchangeable with other crowns.”

In simple terms, the design of the business end of this airbrush ensures that the needle is centered in the orifice through which the needle protrudes. When the engineering and manufacturing of these components is such that the needle is kept “centered,” then the user can achieve some very fine and detailed paint application. The Krome is one of those finely engineered and manufactured tools.

Loading and Applying Paint

I was able to connect the Krome to the hose I currently use for my Paasche and Grex by using the Badger adaptor, part # 50-090. Loading paint into the paint cup is easy. One simply pours the paint into the paint cup, which is an integral part of the airbrush body. The aforementioned video mentions that the lid for the paint cup is a bit loose but I found it to be satisfactory and in no way deficient.

Adjusting the paint flow

Having some experience with a Grex that, like the Krome, uses a Rear Adjustment Knob limiting the “throw” of the needle, I was able to spray fine and consistent lines immediately and without difficulty. I found that the Krome operated nicely at a slightly higher PSI than that which I usually set on the compressor regulator. The spray patterns and lines remained fine and consistent from about 15 PSI up to above 30 PSI.

I opened the adjustment knob for larger amounts of paint and found that I could airbrush a reasonably-sized swath of paint across the wing of my test piece. This is important for me because I build 48th and 32nd scale aircraft and there is a lot of surface area that needs to be covered.

At all adjustments, from fine to broad, I found the Krome to exceed expectations and to be easily controlled.

Cleaning the Brush

I found that on my first attempt at disassembling the brush I had no trouble removing the needle (be careful with that tip!), the needle tube, needle tube spring, and the other interior parts behind the trigger. I also found that reassembly was quick and easy. Moving to the front end of the brush, I found that there was no difficulty in removing the spray regulator and the ultra fine tip. Again, be aware that the tip is not threaded. A pipe cleaner, some cotton swabs, and a few micro-brushes to scrub out the tube through which the needle slides took care of the interior of the airbrush. In about five minutes I had the airbrush disassembled, cleaned, and reassembled.

A few admonitions are included on the product instructions.

- Do not use pliers to tighten the Hold Down Ring or Spray Regulator. Finger-tight is fine!

- Do not attempt to remove the nozzle/tip housing from the airbrush! There is no need to do so and any attempt will result in permanent and irreparable damage to this excellent tool!

- The O-ring seals are made from a new PTFE solvent-resistant material. Even so, old habits die hard and I will not expose those rings to solvent without cleaning them of the solvent immediately.

- The Renegade carries a lifetime warranty on labor. Parts are, of course, extra after the first year.

Conclusion

The Krome is an excellent tool designed and manufactured with precision. This level of precision results in a tool that gives the modeler a “technology edge” when applying paint to a model. The Krome is easy to handle either for a righty or lefty, easy to clean, and deadly accurate in its ability to put a small amount of paint into a very small area.

I heartily endorse this airbrush and give it a high recommendation. Thanks to Badger and IPMS for the opportunity to review the Krome.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews