Aero L-29 Delfin

The Aero Vodochody L-29 was a Soviet and Warsaw Pact primary jet trainer developed and manufactured in Czechoslovakia. The design won a Warsaw Pact competition beating the Yakovlev Yak-30 entry and the Polish PZL TS-11 Iskra. The L-29 competition represented a clean-sheet approach and gave the Eastern bloc its first jet trainer not derived from a fighter. Rugged and reliable the L-29 has since been surpassed by the Aero L-39 and other aircraft, but it continues the soldier on in the air forces of former Soviet client states or break-away republics. Georgia is a notable example, since it has an aircraft manufacturing infrastructure in Tbilisi, and its L-29s are in a state of excellent repair.

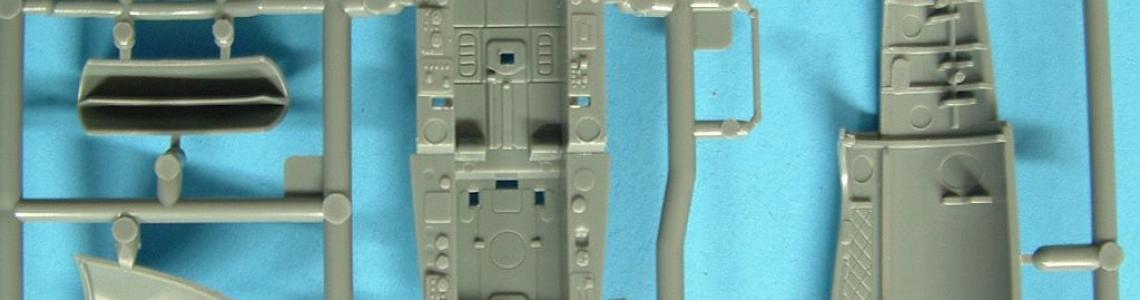

AMK is a start-up model company in Macau, China, this kit being one of its first releases. Previously the only other kit offered of the L-29 in this scale has been the nicely molded, but pricey, Planet Models kit. The kit demonstrates a refined manufacturing process with the parts uniformly and crisply molded with a great deal of detail included. The attention to detail is meticulous and many details are close the resin fidelity – the cockpit, nose wheel well and turtle deck for the sliding canopy being good examples. CAD was used to full advantage. The clear parts are nicely thin and crystal clear (mine required no treatment with future during the build. In addition to the gorgeous plastic, the kit includes a small PE fret, a large and colorful decal sheet with seven schemes and a beautiful instruction booklet. As would be expected the parts are package separately. The PE fret is limited in coverage and only covers flap details, airbrake hinges and underside antenna faces. All in all, the kit is reminiscent of Wingnut Wings in its presentation.

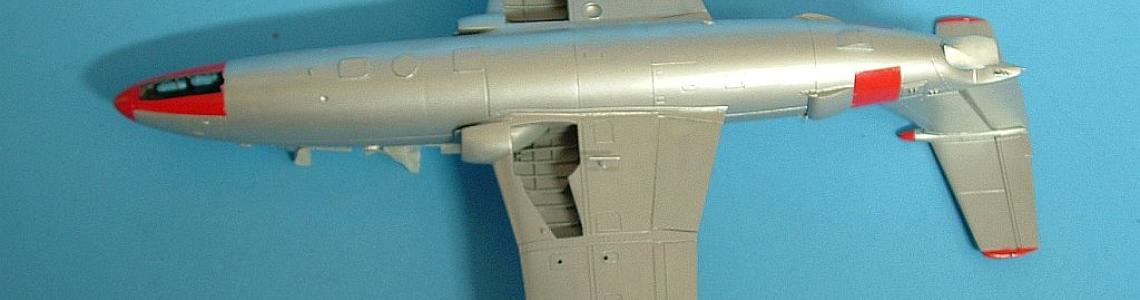

Before tearing into the kit, I had to decide how to pose the completed model and in what markings. I have to say that I like the clean simple lines of the aircraft and it many ways it reminds me of a powered glider. Since Czechoslovakia has a tradition of building gliders, I have no doubt that their tradition influenced the design. AMK provides lots of well-engineered options for positioning components: Canopies open or closed; the nose cover open or closed; airbrakes open or closed; and flaps dropped or raised. After studying photos of the aircraft when parked I opted for flaps up, airbrakes closed, canopies open (a rather odd looking arrangement), and the nose compartment open (to show the detail). The airbrakes on this aircraft do not recess into the fuselage but bump out from the normal contour – perhaps an afterthought or given the low flying speeds, perhaps an engineering trade off to simplify manufacturing. The tougher decision was the scheme – so many to choose from in the kit and in general. I liked the camouflaged look, but in the end was seduced by the high visibility panels. I was inspired by a photo of the Georgian Air Force lineup of L-29s and since I had a Linden Hill decal sheet for Georgia which covered the L-29 that is the route I took.

Assembly

This was a pleasure of a kit to build. Parts required little cleanup and the fit, tight; any problems were mostly self-induced. It reminded me of Eduard’s latest kits. I essentially followed the instruction book, a rare occurrence for me, but the instructions are straight forward. Out of the box, the cockpit is nicely detailed and really is only missing a few things, throttles and seat belts. The fit and detail in the cockpit is also good, including the nicely molded sidewall insulation. I used internet references and I recommend caution, because many pics are of updated aircraft which differ in configuration.

The seats are nice representations of the prototypes but curiously there are no belts in the kit, PE or decal. So I robbed the spares box for some harnesses which if not prototypical look good enough. You have to modify the back seat per the instructions so they will not be interchangeable. The after seat is also a little more complicated in that it fits inside a secondary frame, the purpose of which I could not determine; the instructions are pretty clear on the assembly however. I opted to paint the cockpit Model Master Dull Dark Grey with black finish instruments and panels. I went with black seat cushions and khaki harnesses. The kit provides two options for instrument panel decals and the ones I used worked and look great. I added throttle handles cut from styrene rod once the fuselage was together.

I then moved on to assembling the other components required to close up the fuselage. The nose assembly is a complex affair that assembles easily. It is reminiscent of British aircraft like the Vampire, Venom and Seahawk. There is no radar; this is where the electronics and oxygen bottles are. Again I used a base coat of Dull Dark Gray and then picked out the details. Separately, I assembled, painted and polished the tail pipe. The fit of the cockpit and nose assembly and the exhaust pipe was exact and once in place, start adding weight to prevent a tail dragger.

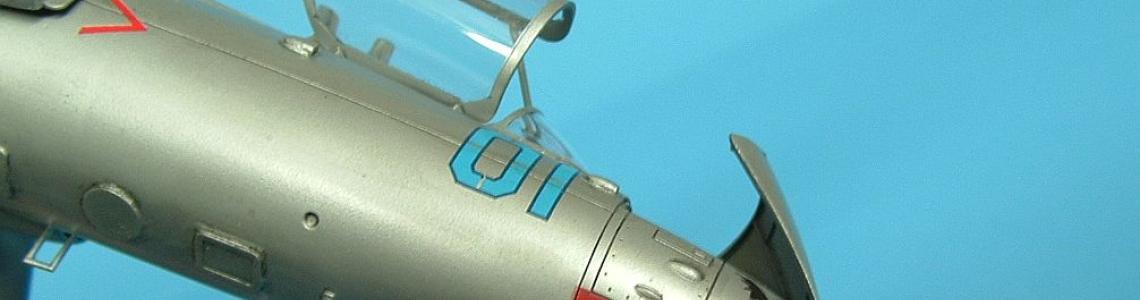

This is not a large aircraft, nor is the fuselage deep, so there is little room for weight. I solved the problem with ceiling fan weights, which are small squares of thin lead which can help balance fan blades. Since I have never needed them for that purpose, I had plenty to use. I folded them over and wedged them in testing the fit of the fuselage halves as I went, until both halves closed. The weight as pictured was sufficient to keep the plane on its nose wheel, since the cockpit is so far forward of the main wheel wells. That done I glued the fuselage halves together for a tight fit all around. The only challenge was fitting the clear plexi-glass panel between the cockpits. I had minor gapping at the top of the frame, which I closed with CA, carefully applied. I chose to deviate from the instructions and leave off the small antennas and the fixed footsteps.

Next I assembled and attached the wings. I started with the intakes, which are a tight fit with little seam issues. While some reviewers have complained that the intakes are not totally true to the prototype, I found them acceptable and used them as is. The wing fit tightly and required very little filling once assembled. The main wheel wells have all of the required structure but could benefit from hydraulic lines and electrical cables. I elected to not add the details, keeping the build as much out of the box as possible. Since I was modeling the aircraft with the flaps up, I did not use the PE and instead clipped off the extensions per the directions. The fit of the flaps in the up position was solid with no gapping. The tail and horizontal stabilizer also went together with no issues.

With the airframe together I started adding details as I worked the other assemblies. For the speed brakes I attached the PE hinges per the instructions and then worked to insert them into the designated slots. It took a little finesse and if I was to do it again, I would put them into the fuselage first and then add the brake. I used liquid cement sparingly to firmly attach the brakes to the fuselage. The other tricky additions were the PE antenna pieces on the underside. Since the underside of the fuselage is curved I worked to curve the pieces; using the small shop PE roller for the job. It was not simple since the PE is thick. In hindsight I should have annealed it first. Since I had gapping along the edges, I used gap filling CA to seal the gap. Adding the antennas, pitot tubes and cooling intakes was by comparison a piece of cake and the fit of each was good. As for the other details, the landing gear and the underwing stores were uneventful. I did pre-paint the tires, hubs and gear and applied a wash before assembling the gear. The main landing gear has the brake lines already molded. I also attached the windscreen

Painting

The aircraft I chose to model is painted in silver lacquer with the red visibility markings. Before starting I masked the canopies and the exhaust pipe. Since the exhaust was covered with MM Metalizer, I could not use tape on it (the Metalizer will lift off), instead I worked a Post-it note around the pipe and sealed it with tape. The nose door was a tight enough fit that it stayed on during the painting process. I pre-shaded with thinned MM Flat Black. For the airframe, I used some of my remaining stock of Floquil Old Silver; paint I will dearly miss when my stocks run out. It is a durable finish which dries quickly, and can be masked. I sprayed it on thin, opting not to pre-shade It was good at highlighting some seam and blemish issues, especially at the wing roots and around the underside PE. Once corrected, I resprayed the affected areas. For the red, I opted for Model Master Guards Red (in their automotive line) because it has a bit of orange, matching the red of the Georgian insignia, and is easier to work with than Fire Extinguisher red in the ¼ bottle; Insignia Red is too dark. I have very little bleed-under or touch up. I then masked and sprayed the main wheel wells and inside of the gear doors Dark Gull Gray. I also masked and sprayed the dielectric panel aft of the cockpit Testors Light Blue from the ¼ oz. bottle. The top of the drop tanks and leading edge of the pylons are weathered black, so I masked and sprayed that color from the White Ensign Miniature line of paints. For the canopies I did not paint the interior color first, because I don’t like the effect on an open canopy. So once the canopies were dried, I hand painted the inside of the canopy matching the mask line. These canopies are thin enough that the effect is good.

The kit decals were easy to use and responded well to Micro Sol. I found them in register, easy to move around and with good opaqueness. The glare shield decal worked great. I put the cover in place, applied the decal and then cut it with a new No. 11 blade. The only issue was a slight overlap of the windscreen which I overpainted by brush. The Linden Hill decals were also good, but the roundels are thick under the Georgian Star and took several applications of Solvaset to sit down in to the panel lines. I clear coated the decals with Future applied with a Q-tip. I accentuated the panel lines with Warpigs Wash – Dark Gray which I allowed to dry before removing. I find this method leaves the slightest hint of staining, an effect I wanted. I applied Testors semi-gloss clear coat with drops of dull coat added to further flatten the semi-gloss. I took it too flat and resprayed the straight semi-gloss. In some areas the silver lacquer looked uneven, so I re-sprayed some panels with Old Silver until I achieved the uniformity of reflectance I was looking for. The result is some subtle aging.

Finally assembly was straight forward, except for the drop tanks and the main gear doors. Normally I like to attach the pylons before painting, but since the tanks are molded to the pylon, sit close to the wing, and had to be masked and the upper surfaces sprayed black, I had to leave them off until final assembly. I decided to fit the main gear and the main gear doors first. The directions are vague on the relationship of the outer gear doors which overlap. Also missing is an actuating rod which attaches from the lower main gear door to the landing gear main strut. Using photos I was able to achieve the correct relationship, spacing and add the actuating rod. The problem – my completed assembly would not allow the drop tank and pylon to fit properly (perpendicular to the ground. So the pulled the gear doors off, added the drop tank assembly and then reattached the gear doors with a shorter actuating rod. The inner doors and their actuators was trouble free. The actuator on the nose gear was a small but not insurmountable challenge to fit the cylinder in the whole provided – it is just hard to see around the detail. The aft nose gear door actually flips 180 degrees with the interior side fully exposed. The forward door is normally closed, so I had to add some strip styrene in the well to allow it to rest flush with the fuselage. I popped the clear lenses for the marker light into the wings and coated them with the Tamiya clear color coats. The landing light lens in the wing was a drop in fit with white glue. I attached the canopies with quick setting epoxy with a prop to hold each section in place. The forward canopy has little bumps to rest on representing the hinge. When dry the canopy received the hold open device. The sliding canopy fit nicely into the track.

Overall this kit was a very satisfying build and the fact that the aircraft it is not well known in the US, plus the Georgian markings generated a lot of interest within IPMS Tidewater.

My summary of minor kit issues:

Disappointments

- No seat belts

- Drop tanks molded to the pylons

Challenges

- The fit of the outer gear doors vs the pylons

- The glass between the front and rear cockpit

These minor issues says a lot about the high quality of the kit, which I strongly recommend to anyone looking for a pleasant build of an important if overlooked aircraft.

Thanks to AMK for supplying the review sample.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews