AEC Mk.II Armoured Car, Part 2 - Chassis, Engine, & Exterior

Part 2 Review – Chassis, Engine, & Exterior

This is the second of a series of reviews of the MiniArt AEC Mk. II Armoured Car kit. Part 1 previously reviewed the kit contents and assembly of the driver’s compartment. This review includes the chassis, engine, and exterior. A subsequent review will include the turret and gun. Model Rectifier Corporation (MRC) has generously provided the review sample to IPMS.

Introduction

This is an excellent, highly detailed kit. The molding is very crisp with great detail, and the fit is excellent. There are a few difficult areas that will make the kit challenging for less experienced modelers, but it results in a nice, fun to build kit for more advanced & expert modelers.

Chassis

Steps 16, 17 and 18 start the installation of the chassis. Take care in aligning the springs, parts Ad5, in the correct direction so that the axle mounting plates Ba4 and Ba5 slope in the right direction. The mounting plates should be parallel with the chassis. There are several parts here that could just as well been molded together such as Ba4, Ba5, B20, and B21.

In step 18, I installed the chassis rail assembly B17 to the body first before installing the three cross members to assist with their alignment. Part F5 is not perpendicular to the frame rails when installed.

Step 19 included small, thin parts in E25 and E26. I inserted them, glued them together, but left the other ends free so I could align them to the transfer case in step 21. I left the parts glued together but not fixed in place until the transfer case was located.

The location of the transfer case, assembly 20, in Step 21 is not very precise. It is possible to wait until step 31 and install the transfer case with the engine to get it accurately located. In step 22, E27 does end up being installed at an odd angle between the two chassis rails.

Engine

Steps 23 thru 29 are the building of the engine, which makes a very nicely detailed assembly. Part Ba63 in step 29 is very small and not well anchored so be careful to not break it off. Detailed colors are not provided for the engine so I used several shades of gunmetal for a metallic look.

Prior to step 31 is a good time to begin painting the underside of the car, prior to installing the engine, transmission, muffler, etc. The kit includes 4 color and marking schemes, I chose scheme 2 and used Tamiya dark yellow XF- 60 as called out for the base color of the car. The engine is installed at an angle in the chassis, not parallel to the rails.

In step 33 I painted the exhaust pipe and muffler Vallejo dark rust and used MIG standard rust pigments to create a rusted look.

In step 33, again check to make sure the leaf springs are oriented in the correct direction so the axle mounting plates are parallel with the ground. The leaf springs are attached with some small brackets that don’t seem substantial enough for a vehicle weighing twelve tons. The axle/leaf and leaf/frame joints both broke later when I was trying to get all four wheels on the ground.

Step 36 includes the brake assemblies and photoetched metal shields. I found this step to be very difficult. The photoetch brackets are shown to be a butt joint with the curved photoetch shield. I did not think superglue would be sufficient so I decided to solder the two pieces together. Soldering was difficult with the small pieces but I think ended up with a much stronger joint. Miniart should rethink how these shields and brackets are fastened together. The shield brackets could have tabs added to provide a stronger joint with the curved shield. The shield assembly looks nice when completed despite the roughness of the solder joint.

Both drive shafts in step 38 are labeled E6 but the short one should be E7.

Joining the ends of the axle at the leaf springs in Step 39 creates a week and unsightly joint. Seems like it would've been better to join the axles at the differential. This joint also contributed to the wheels not touching the ground later on.

In step number 40 it would be nice for Miniart to provide a form or template for bending the photoetch for the axle skid plates. The holes in the skid plate need to align with the bolts in the ends of the axles.

Steps 42 through 45 are the assembly of the wheels and tires. The tires are very nicely molded without a mold seam down the center of the tire. There are transverse seams at points along the tire that are difficult to remove but will be visible. Steps 42 & 43 are the front wheels. Note the direction of the tread on the tires so they will both face in the right direction on the completed model. In step 44 and 45 careful gluing of parts Ad18 will allow the wheel to spin on the inner plate. This might be possible on the front wheels also with very careful gluing of parts Ad22.

Step 46 is the installation of the tires, which I did not install at this time until painting of the exterior is completed. I also did not install the braces, parts Ab5, until later fearing that they would break off.

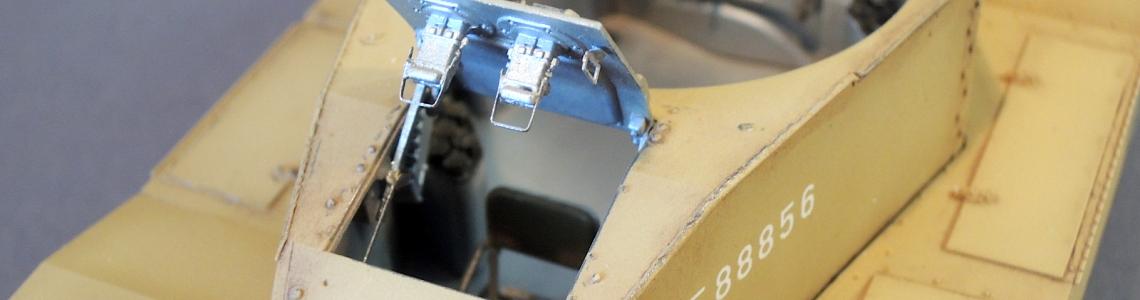

I attached the driver’s hatch in the open position to display all the nice interior detail.

In step 51, not sure why the photoetch parts PE1 and PE2 are necessary. The interior framing is completely concealed in the assembled PC and the parts could just as well have been molded in plastic. In actuality the louver PE2 rotates, but that does not appear possible in the kit. The bolts, parts Ae1 are miniscule, I left part of the spruce connection attached for handled until glued. Miniart provides extras but I managed to lose them. Would have been easier if the louver and bolts were all molded as one piece.

Step 53 installs the top cover on the body and encloses the interior. I applied a MIG dark wash to the interior and completed some of the detail interior painting prior to installing the top cover. I did not install the glass windscreen part Gd2 at this time and will wait until exterior painting is completed. The support rod for the engine hatches, part E41, is ok if the hatches are closed, but weak if the hatches are installed open to show off the engine detail.

Do not install the detail pieces in step 55 until after the fenders are installed on the body. I broke each of the mounting stems for the rearview mirrors getting them off the sprue, and broke off and lost the driver side mirror after installation. The stems for the mirrors would be best replaced with brass rod. No clear glass lenses are provided for the rearview mirrors so I just painted them silver.

Step 57 completes assembly of the chassis and exterior. Everything has been painted Tamiya dark yellow XF-60. Some white was added and the center of the panels lightened slightly. The decals were applied and a dark wash applied to the exterior. Decals are made by Begemot. The decals have a matte finish, are very thin, and held together well during application. The details snugged down ok with MicroSol, but not enough to conform to the rivets on the rear deck. For the simple two-color decal in this scheme it would be easier to mask and paint the stripes.

At his time I installed the wheels on the vehicle. The rear wheels are substantially anchored, but the front wheel joint at the ball on the end of the axle was not sturdy and difficult to get the wheels aligned. It’s not possible to turn the front wheels. While gluing the wheels I tried adding weight to get all four wheels on the ground, but it didn’t work. I broke the axle connections but still couldn’t get all the wheels on the ground.

Summary

This has been a fun, challenging, and rewarding kit. The detail is excellent and the fit of the parts is as good as any other manufacturer (with a few minor exceptions). It’s a pricey kit due to all the parts, and is an enjoyable, but complicated build.

I’m grateful to Model Rectifier Corporation (MRC) for providing the review sample of this great kit, and to IPMS for letting me review it.

All that’s left now is the turret and gun – 21 more steps with massive amounts of parts and great detail – almost a kit in itself!

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews