75mm Pack Howitzer M1A1 & Gun Crew

Following their release of the 75mm Pack Howitzer with ¼ ton truck and crew, Bronco has released a British airborne version with a crew of five. When this kit came up for review, I had just finished building Vision’s 75mm Pack Howitzer and thought it would give me an opportunity to compare the two kits. Much to my surprise the Bronco kit is the Vision kit with a new sprue added to detail up the original kit. There are two sets of trails on the pack howitzer. The front trails and the rear trails. Both sets are hollow, with lightening holes on the sides. The hollow front trails house the equilibrator springs and the rear trails are just hollow. Vision released the original kit with a one piece molding of the rear trails, which looked okay but really didn’t represent the hollow trails to well. In the Bronco release you get the entire Vision kit along with a new sprue of parts that better represent the hollow rear trails. In addition there are smaller molded parts to better detail the undersides of the bottom of the cradle and a nicely detailed lunette and tow pintle. You also get a new set of tires with the British tread pattern and a gun crew of five airborne troops along with their personal weapons.

Construction

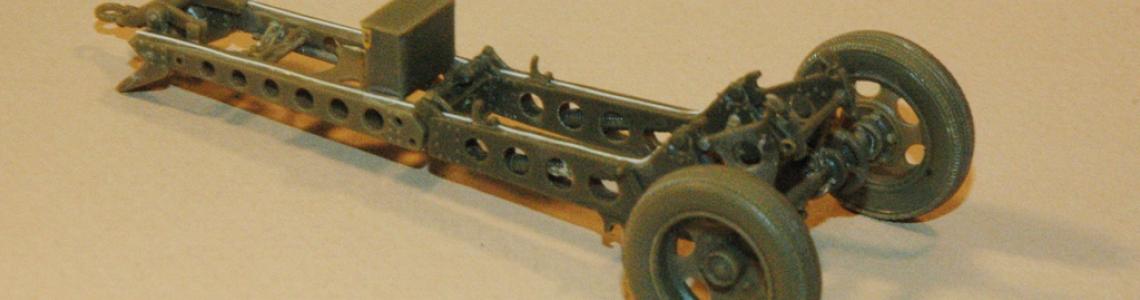

Construction begins with the hollow rear trails. Simply glue the two sides together and add the hand spikes (B13 & B14) along with the tow bar mounts (Kd18 & Kd19). If you plan on using the PE pole brackets and footman loops, those should wait till later as they may break off during the remainder of the assembly of the trails. I personally didn’t use the pole brackets. During my research of the pack howitzer, I couldn’t find any images of a gun with the poles mounted on the sides of the bracket. And on at least two of the PE pieces the gluing surface is so small I don’t see how it can be glued without making a mess of the trails. I did test fit the handling poles (Kd4) into the opening on PC11 and they wouldn’t fit without trimming. So I elected to not use the brackets on the outer sides of the rear trails. I also didn’t use the PE footman loops. I attempted to bend a few but just couldn’t get it done, and I really don’t like how they represent the real loop. They are flat and just don’t look right to me. With the ability that Bronco has for fine molding I don’t know why they don’t mold plastic footman loops. Other model manufacturers have done it and Bronco has certainly proven they can mold fine details. So come on guys give us plastic footman loops.

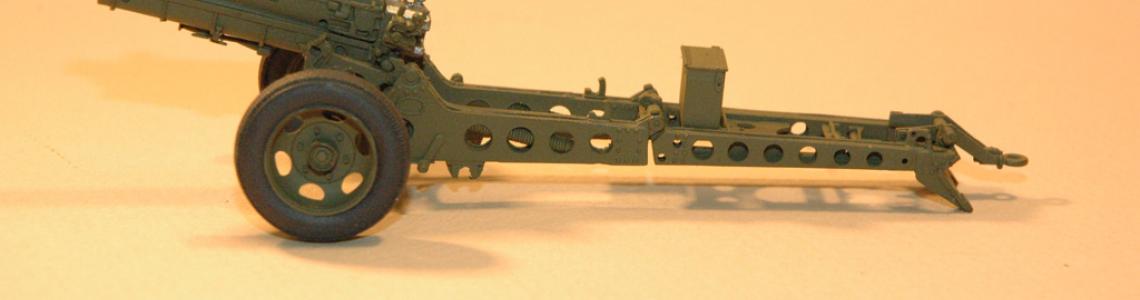

After the two side pieces are assembled they can be joined with the cross braces (Kd2, Kd3, Kd26 & Kd31). Be sure that the two trails are square and parallel. The tow bar (Kd8) can wait till later. Assemble the multi part lunette and add to the rear of the trail assembly. This assembly is much nicer than the original Vision piece, which consisted of only three parts. The bronco version includes the locking pin and brackets to lock the tow bar and pintle. Once this assembly is completed the tow bar can be added. Simply depress the two arms and insert the pins in the mounting brackets (Kd18 & Kd19) added to the trails earlier. Once the tow bar is inserted it can be fit between the two brackets on the lunette. It may need minor sanding to get it to fit between the brackets. All in all the rear trials build quickly and are nicely detailed.

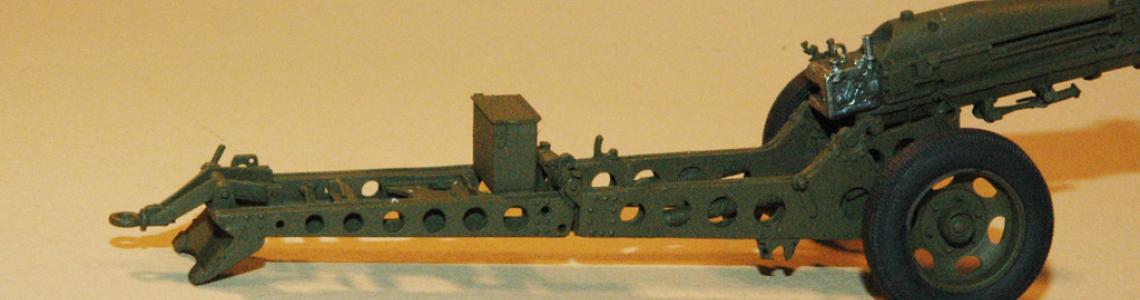

Moving on to the front trails we are now dealing with the Vision parts. These will need some clean-up work. They have some minor flash, which is easy to clean up but they do have some knock out marks that need attention. These are deep and have flash that needs to be cleaned up. Especially in the front, where the rocker assemblies will fit. The equilibrator springs are molded in each half of the front trail. Once assembled they represent the actual spring nicely. Begin assembling the front trails by adding the five PE bolt heads (Pc13 & Pc15) to the inner wall of the front trails (B1 & B4). Be sure to use a sharp #11 blade as that’s the only way you can pick up these tiny pieces. Once they are added the front cross brace (Kd28) can be added. Now add the elevating worm gear shaft (B30) by slipping it through the front cross brace and gluing it to the upper and lower worm gears. Now you can add the lower plate (B17). Again be sure the plates stay square to the trail side. Take this assembly and add the rocker assembly (B8) to the pinion on the outer half of the trail (B2) and glue the two half’s together. For now only glue the front two thirds together, leaving the rear third until we add the assembled rear trails later in assembly. When gluing the half’s together be sure to not get glue on the rocker assemblies, otherwise they won’t be able to elevate. I rotated mine upwards to move it out of the groove when gluing. Now assemble the left front trail the same way as the right one. Bring the two sides together fitting the cross bars (B31 & B32) in the rocker assemblies and the front trails then the rear cross brace (B18). Now slip the pins at the top of the rear trails between the mounts at the rear of the front trails and glue the rear third of the front trails together locking the rear trails in place. If you were careful when gluing the trail half’s together, the two rocker assemblies (B7 & B8) should be moveable. At this stage I added some extra details to the trails. The half’s of the trails were welded together. However, neither Vision nor Bronco has this detail. So I added the weld beads to the top and bottom of the front and rear trails. I used .010” Evergreen Styrene rod but stretched sprue would work as well. Another detail that can be added is improving the elevating cranks which are molded into the sides of the front trails. Included on the original Vision sprue “B” are a pair of elevating cranks (B38) that are nicely molded, albeit fragile. I discovered these accidently and after the wheels were added so trying to add them at that stage would have been difficult. If you can remove the cranks without breaking them, simply carve off the molded cranks and add these for a nice touch. Glue together the tool box (Kd29 & Kd30) and add the PE latches to the sides. This assembly is then added to the top of the rear trail as shown in the instructions. Next step is adding the oil can. Part Kd7 and PE part Pc4. You will need to add a spout made from fine wire or stretched sprue. Again I left this off as I couldn’t find any images of oil cans mounted on the trails of any pack howitzer.

Next assemble the axle by adding the traversing hand wheel to the area indicated. Once this assembly sets up it is time for some dry fitting. In the original gun the axle is inserted into the axle bearings on the front of the trails. You can see a flat spot on the axle. To insert the axle, the gunner would rotate the sleeve lock (that small handle on the bottom of the axle) 90 degrees and using that as a handle for the left hand and his right hand on the elevating wheel, he would rotate the axle until the flat spot is on top. Then the axle would be inserted into the axle bearings and rotated downward 90 degrees until the flat spot was facing forward. This locked the axle in place. Now the assembly of the models axle onto the front of the trails is accomplished the same way. With the flat spot up, dry fit the axle into the axle bearings. Some trimming and sanding will be necessary. But once the area is cleaned up, the axle will be able to be inserted and rotated locking it in place with no glue necessary. However, do not add the axle to the model just yet. There is some work that needs to be done with the wheels first. As stated earlier Bronco supplied the British pattern wheels. However, there is a problem. The hole molded in the wheel back (Kd32) where the axle mounts is too large and the axle end just drops down into the wheel. Test fitting the Vision wheels onto the axle will show what the problem is. I filled the hole with styrene rod and drilled out the proper size hole so the wheel fits. Now place the axle onto the trails first then glue on the wheels. If you glue the wheels on first you may have a tendency to grab the wheels to rotate the axle into place. The glue joint between the axle and wheels is very weak and trying to rotate the axle into place by using the wheels will easily twist them right off, damaging the axle. It won’t be necessary to add the PE bars (Pc6) and wing nuts. These were unnecessary to lock the axle in place and I could find no reference that they were on the original gun (TM included). Adding the axles and wheels completes the trail assembly.

The gun itself consists of three main parts. The cradle (B37), the top sleigh (B35) and the bottom sleigh (B36). Bronco has included detail pieces that need to be added to the bottom of the cradle (B37). These are some tiny moldings and magnifiers will be needed to see where the sprue ends and the part is. These are what I assume are part of a trail lock for moving the gun with the gun assembly in the firing position. Test fit the cradle into the rocker assemblies some trimming will be necessary to get them to fit. The pins for the front lock will have to be trimmed as the instructions indicate to get them to fit between the front locking brackets at the front of the rocker assemblies on the trails. I opened up the locking bracket at the rear of the rocker assemblies to get the rear pins on the cradle to fit. Then after trimming the front pins I was able to rotate the cradle down between the front cradle locking brackets. Now that that fits you can remove it from the rocker assemblies and add the rear of the cradle (B34) and move on to the rest of the gun. Part Z1 is a metal sleeve that fits over the gun barrel molded at the front of the bottom sleigh (B37). It is not the gun barrel which is the part that the sleeve fits on. There is a notch molded in the gun barrel and a hole in part Z1. When placing Z1 onto the gun barrel, be sure the hole and notch line up properly so the lifting ring (A4) will fit into the hole on the outer sleeve. The notch in the gun barrel may need to be opened up a little more. My sleeve did not go all the way on until I opened up the notch a little bit. The Breech block is added to the back of the bottom sleigh and the rear lifting ring (A5) added to the top of the breech block. Now move on to the top sleigh (B35). On the actual gun, there are hooks located on each side at the front and rear of the top sleigh. The top sleigh fits down over the bottom sleigh and is then pushed forward where the hooks lock on the bottom sleigh. These hooks are present on the models top sleigh. However, only the front hooks are molded open. The rear hooks are molded closed and opened up before the part will fit. Unfortunately this is not mentioned in the instructions anywhere. A couple of quick swipes with a sharp #11 blade will open the hooks properly. Look closely and you will see what needs to be cut out. A simple fix but it should have been pointed out in the instructions. I knew because this step is pointed out in the Vision kit. Once the rear hooks are open you can add the front and rear handles. The front handle (B26) has a positive locating hole, but the rear handle needs to be fiddled into place and takes a little patience to get it on. Now snap the top sleigh down over the bottom sleigh, lining up the hooks at the front and rear. Once they are lined up push the top sleigh forward locking it in place. No glue necessary. Now glue that assembly down onto the cradle and add the gun sight (A1). Now snap the rear cradle locking pins into the previously prepared rocker assemblies and rotate it down until the front locking pins are at the front locking brackets and glue the gun in place. Paint the gun overall olive drab and the gun breech in either dark green or gun metal. The traversing wheel is brass and the bellows khaki. Paint your tires your favorite color and you are done with the gun.

Figures

The five airborne figures are rendered quite nicely. They all are wearing the later three color Dennison smock with the snap cuffs and snaps for the tail piece. The lower half of the smock is molded separately in two pieces that defines the thin jacket. Each figure is equipped with two magazine pouches, a canteen and entrenching tool. The figures have depressions in them where the magazine pouches fit helping them to become a part of the figure instead of lying on top of it. Nice touch. Also there are depressions in the legs of the gun captain that give a positive location for his hands as he is leaning forward with his hands on his thighs. These help in aligning the figures arms. There is a standing figure with his right leg up on the rear trail holding the top of a 75mm round in his hand with the bottom of the round on his raised thigh. There is a depression on his thigh that aligns the round. Once assembled the gunner is kneeling looking through the gun sight with his right hand resting on the trail and his left around the front adjusting the gun sight. While putting the figure together I was able to place him next to gun and make minor adjustments to his pose before the glue set up. I was able to get him to fit with very little trouble, thanks to the design of the figures and the molding. Nice job Bronco. Both the kneeling figures have separately molded soles on the bottom of the shoe that has beautiful hob nail detail molded in it. The figures are all wearing the distinctive airborne brain buckets. They each have the chin cup and double strap where the front strap attaches to the helmet just forward of the ear and the rear straps meet at the center of the rear helmet. The netting on the outside of the helmets is rendered a bit soft but adequate once painted and dry brushed.

As mentioned the figures are wearing the later Dennison smock. These were three color brush camouflage. Meaning the dark red and dark green pattern was brush painted over the base dark yellow. Searching on line for the Dennison smock will show quite clearly the unique camo pattern. The instructions point out the figures for the camo pattern except for the base color. My research shows that a dark yellow would work fine as a base color along with red brown and dark green. One nice feature of the figures is the molding of the legs. They are molded bulky like the real trousers. Often British airborne troops have legs that are a little too thin for my taste.

This is a very nice rendering of the 75mm Pack Howitzer. The hollow rear trails add nicely to the original kit. I can recommend this kit to anyone looking for a decent pack howitzer for their collection. The inclusion of the entire Vision kit will allow the modeler to build any version of the pack howitzer which makes this an even better bargain. The assembly is not difficult and it really is a quick build and should be within the ability of any modeler. Many thanks to Bronco Models for continued releases of these small artillery pieces. I would also like to thank Dragon Models/USA for sending it to IPMS for review, and thanks to IPMS for letting me review it.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews