7.5cm PaK 40/4 RSO

History and Performance

In the summer of 1943 a proposal was offered by Steyr Werke to the Ordnance Department for the mounting of a PaK 40/4 on a RSO chassis as a small self-propelled anti-tank weapon. 60 machines we converted for testing. Combat trials on the East Front began in early January 1944.

The Kit

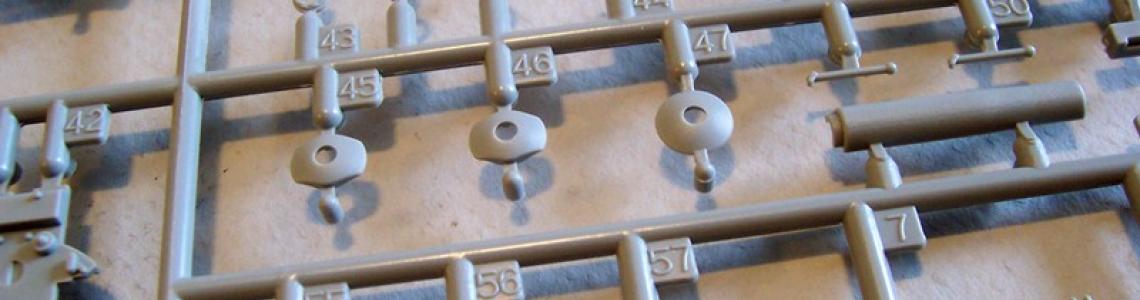

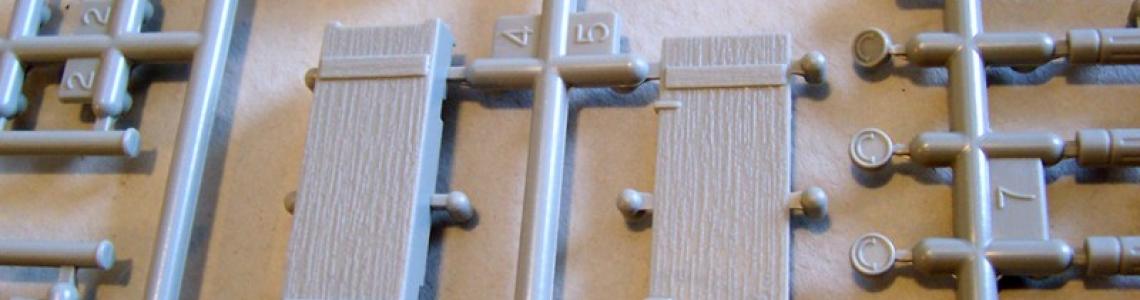

The kit is packaged in Dragon current sturdy box, with a color image on the front and a montage of features on the box bottom and sides. The box top shows that over 460 Parts are included. There are eleven sprues, molded in the familiar grey plastic with crisp detail. The hull and chassis front are molded separately.

Instructions - The instructions are typical Dragon, with eight fold-out pages. There are a total of 21 construction Steps, with numerous subassemblies noted. Very busy for such a small kit, but it gets one’s attention. There are no unused Parts indicated.

Sprues and packaging - The sprues are individually packaged. Two ammunition boxes with separate lids, live rounds, shell casing and canisters are included. The wood grain on the boxes is raised and will assist in the painting process.

Clear Parts - There are no clear parts included.

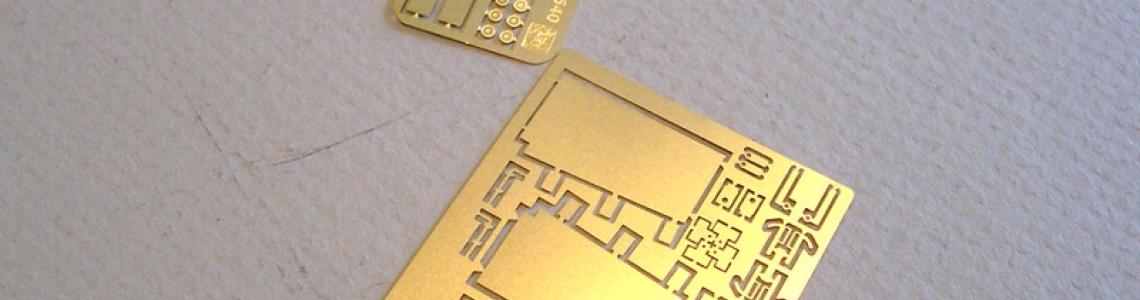

Photoetch - There are two small photoetch frets included, along with two small, fie wire metal handles which are packaged with the photo etch. Had I not reviewed the instructions I would not had seen these very small parts. Not being aware I lost one of the handles at some point while examining the box content.

Figures - There are no figures included.

Running Gear and Tracks - A single package of individual link tracks are included.

Decals/Markings - Decals are provided for seven Eastern Front vehicles, along with stencils for the munitions included. Actually, there are no markings for the vehicle, other than an impressive number of kill rings on the gun barrel for one vehicle. The vehicles are shown in winter white-wash, one in yellow, and the remainder in the tri-color scheme.

Construction

Engine/Transmission - There are six construction Steps for the engine and drive shaft. Dry-fitting of all parts is highly recommended prior to the application of solvent. Placement of some Parts is not very clear. The 16 very tiny individual rocker arm covers is just plain silly, in my opinion. These Parts are very small and difficult to clean up. Careful study is required to determine the top and bottom sides. Parts E17 and E18 are used for the shaft between the two blowers. These parts are quite fragile and care is required to avoid breakage. The two parts are different and intended for use with a specific part: don’t mix them up! Part E15 is a shaft and should be replaced with .020” plastic rod, as the kit Part will be difficult to clean up. The fan belt and pulleys (Part E36) is also quite fragile. Fix it in place before attempting to remove the sprue attachment spur. I did not do this and broke mine.

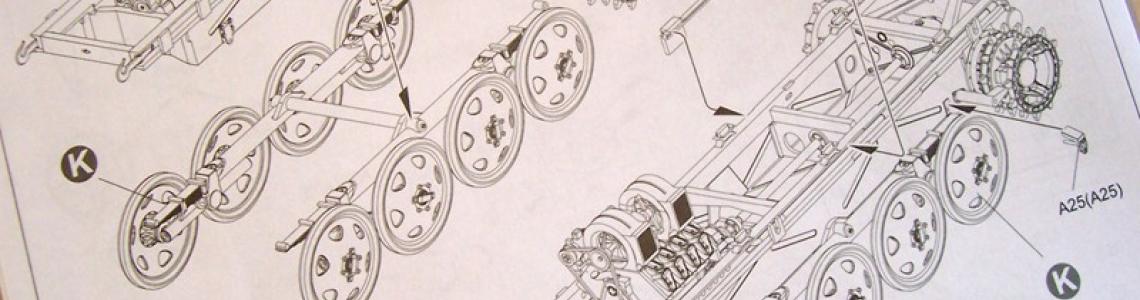

Running Gear and Tracks - The sprockets are attached to the sprue runners at points between the teeth, rather than at the tip of a tooth. The attachment must be carefully cut to avoid damaging the adjacent teeth. I did manage to shear of one tooth from two sprockets (battle damage?). The front and rear sprockets are fixed in place, and will not rotate: this will create an alignment problem when fitting the individual link tracks later in the build. Step 4 addresses the construction of the running gear: care is required to assure that all parts align properly for later attachment to the hull. Part B10 is a mounting hub that inserts into the road wheels inside face for attachment to the axles. This mounting hub needs to be fully seated in the wheels’ female opening. A few of mine were a tight fit, and without a visual inspection one would think the hub was fully seated.I left the road wells on the sprue while attaching the mounting hub and photoetch. Each photo etch parts require four folds before being fixed to the outer surface of the wheels. Each photo etch part has small opening at each end, which I believe is intended to fit over the retainer nut. I found the fit to be somewhat better if the two nuts opposite each other were shaved off; otherwise the PE Parts stand proud from the wheel’s exterior face.

Lower Hull -The parts build into a rather sturdy hull tub. I would suggest fixing Part A21 to the rear hull first, and allow it to harden thoroughly before Part B8 is fixed in place. The driver’s compartment is assembled in Steps 8 and 9. My references indicate the seats included in the kit are incorrect and should be replaced. I had a spare set of seats from a Sd. Kfz 251 that were modified a bit and fixed in place. The crew hatch covers are furnished in both plastic and PE. The driver’s hatches are a bit shorter in length than the co-driver hatches so check them before applying the solvent. The hatches are comprised of two parts that apparently are hinged in the center, and swing over the outboard side of the crew compartment. The center hinges are not indicated. The fine wire handles are shown fixed to the inside side edge of outboard hatch, but that creates a conflict when the retainer latch is set in place unless the handles are mounted properly (mine were not!).

Upper Hull -The driver compartment and gun platform are shown installed on the chassis in Step 11. The placement of the platform should be deferred until after the PaK cruciform base is assembled and fitted to the chassis. The opening in the platform is nicely fitted over the cruciform. Step 20 shows the installation of two rear-facing crew seats. Each seat is made from a bottom frames with a fabric band, plus a long-legged “U” support. The attachment legs on the seat bottoms were extremely tiny and would not offer much support for the seat bottom. The “U” supports were also quite fine (one was broken on the sprue and I broke the other while trying to remove it from the sprue. Superglue was used to hold everything in place.

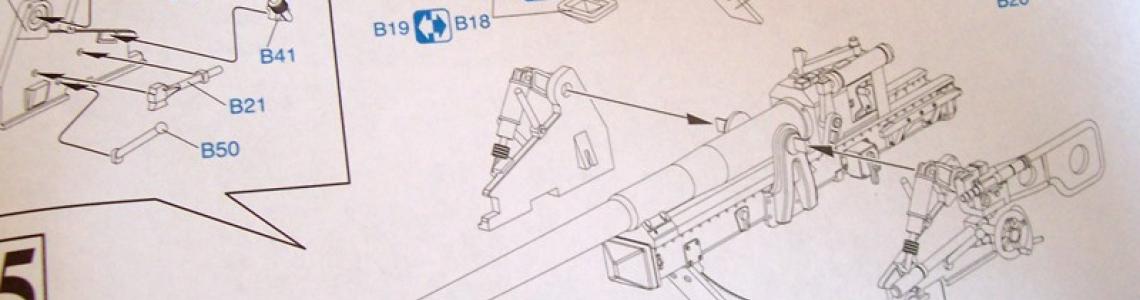

Armament - the 7.5cm PaK builds quite nicely with no issues, other than the small parts involved. There are several Steps involved in this subassembly, so the individual steps must be studied closely to avoid conflicts.

Finishing/Painting

The model was build and painted in several sub-assemblies before assembly. Tamiya paints were used throughout with oils being used for weathering. Fitting the engine and transmission in place is a challenge, but is doable with some minor trimming of tabs. The gun platform fits onto the chassis and is fixed in place with six tabs that fit into recesses in the bottom of the platform. The driver’s compartment should be fitted in place first, then the gun platform. I found that even with this step the tabs would not seat into the recesses properly.

Decals - The vehicle I decided to model had no markings, but from past experience with Dragon kit’s the decals usually work quite well.

Conclusion

The finished model is quite interesting and different, and does not share the glamour of Panthers, Shermans and Tigers. This is indeed another interesting kit from Dragon, and will offer some potential for the diorama builders. Although the kit is well engineered the builder must constantly check the alignment of the many subassemblies to avoid misfit later in the build. Everything fits, but at times the fit is tight. Review the instructions thoroughly. This kit is intended for experienced builders due to the many small Parts and complex sub-assemblies. Care is required when removing some Parts from the sprue to avoid damage to the Parts. The finished model is quite delicate, and therefore care is required to avoid breaking the suspension (for example!) and other Parts.

Recommended as an unusual topic.

I wish to thank and IPMS/USA for the opportunity to build and review this kit.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews