60-Spoke Wire Wheels

3D Model Parts is a new U.S. based company that uses 3D printing technology to produce resin ship, automobile, aircraft, and armor detailing accessories. 3D states their printing process produces details with greater precision than either injection molding or resin casting.

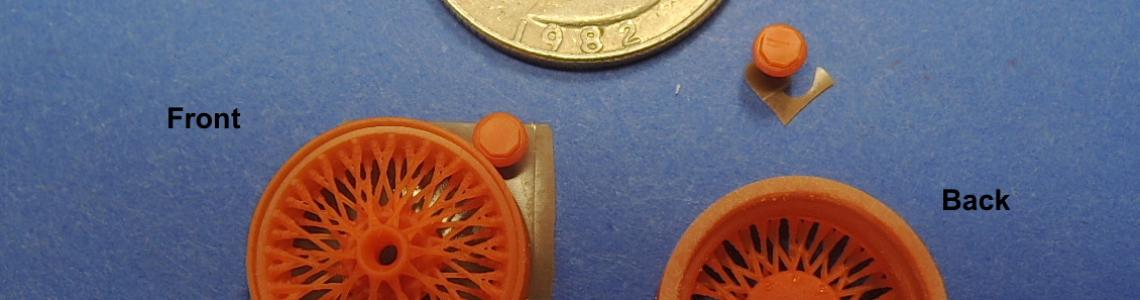

This set of 1/25 scale wheels certainly lives up to that claim! The spokes have amazingly fine detail, and the wheel rims are extremely thin. The interlacing of the spokes makes the wheels very realistic at this small size. I compared the 3D wheels to wire wheels from a Revell kit and there is no comparison. 3D accurately reproduces the opening between spokes, where many of the openings on the Revell wheels are filled with flash.

The set includes 5 - 3D printed wire wheels with separate interlaced spokes and knock-off hubs for each of the wheels. 3D says the wheels work with enamel or acrylic paints and CA glue. The wheels are scaled to 15" x 5" wheels. The wheels come with a ‘wafer’ on the backside that is apparently part of the printing process. The knock-off wheel hub is attached to the same wafer. The instructions describe how to rub the backside of the wheel on sandpaper to remove the wafer. A sprue cutter or hobby knife can also be used to remove the wafer. 3D states that the resin is less brittle than cast resin, but I broke the edge of a wheel rim when installing it in a rubber tire. One of the wheels was also damaged when I received the package. I think the damage to the parts is due to their incredibly thin pieces.

Washing the parts using warm soapy water, isopropyl alcohol, mineral spirits, or paint thinner is suggested to remove any residue from the printing process.

I removed the wafer by rubbing the wheel on a piece of sandpaper and washed the part in warm water. There was no other clean up necessary. I glued on the knock-off hub with CA glue, and painted the wheel with Alclad’s black base and chrome finish. The resulting wheels are beautiful, with extremely fine detail. The painting did bring out a miniscule waviness to the spokes that must be part of the printing process, but it is difficult to see without magnification.

These details are pricey, but have great precision and wonderful detail. The extremely fine detail produced with this process opens up lots of possibilities for models and add-on parts.

Very nice work! Thanks 3D Model Parts for introducing this fantastic new process and providing IPMS with review samples. I look forward to using more of their products!

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews