1941 Ford Custom Woody

Growing up along the Central Coast of California it was common to see Woodies for all types throughout town, at the car shows, school parking lots, and definitely at the beach. They were as familiar as the Volkswagen Vans and Chevrolet Corvairs. Not as frequent as Volkswagen Bugs or Ford Mustangs. I always thought of them as beatnik wagons as those that drove them seamed a little disheveled looking.

AMT Round 2’s re-release of the 1941 Ford Custom Woody is a valued addition for those modelers who prefer the quieter and more functional hot rods of the time. Face it, not too easy to haul 2 surf boards 30 miles up the coast to your favorite break in the back of a Ford 1929 T bucket. Panel wagons and Woodies were the main ride for the surfer beach bums of the 60’s and 70’s.

Parts Count

- 4 Vinyl Goodyear Eagle Tires

- 1 Cream Styrene 41 Woody Body

- 31 Chrome Styrene Parts on 1 Sprue

- 6 Clear Styrene Parts on 1 Sprue

- 64 Cream Styrene Parts on 11 Sprues

- 1 Piece of Flat Acetate for Side Windows

- 1 9 Step Instruction Booklet

- 1 4”x6” Decal Sheet with Decals for Wood Panels and Surf Board Art.

- 1 Mini Box Art/Box

- 1 2015 Round 2 Catalog

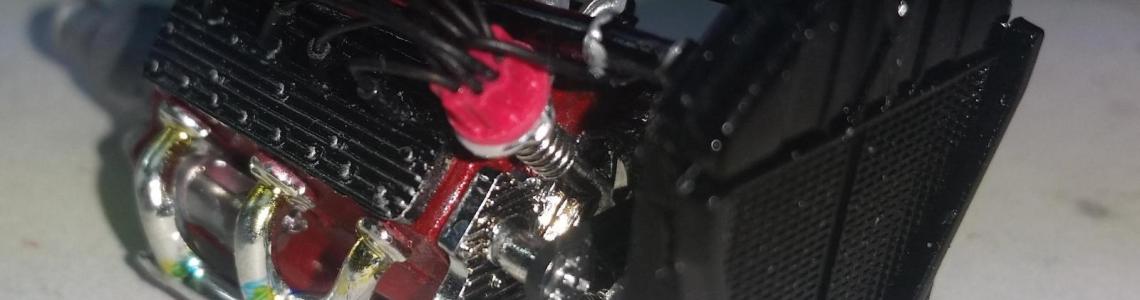

Construction of this kit starts with the 2-part assembly of the Ford flat head and radiator shell. Extra care in painting the details and sub assemblies will net you a more than satisfactory mill. I chose to replace the distributor cap with one of the pre-wired from MAD Industries. If you decide to go this way remove the distributor cap from the end of part 520 very carefully and then glue the pre-wire distributor cap only in its place. Take care when drilling the holes for the spark plugs as to stay perfectly in the center of the head. I could give you the firing order but then what would you learn. Goggle flathead Ford firing order and you will get a small visual education on a common hot rod motor.

Once the engine is completed the process of building the interior begins. Again that extra step in painting will yield you a fantastic looking interior. Time was taken to mask and paint with the airbrush all the interior panels, seats, floor, instrument panel, steering wheel, and dash. The flooring was flocked with Ken’s fuzzy fur and the interior tailgate was trimmed in Bare Metal Foil. More time was taken to hand paint every hinge, handle and rivet. I might add that the exterior color carries over to the interior wheel wells, dash, steering column, and floor pan bottom. These were all sprayed when I was painting the body of the car.

Simultaneously I was working on the kit chassis, which mounts, directly to the interior floor pan. Here I made two slight modifications to the kit to hopefully improve the rake of the vehicle. The front cross member #525 had a 1/32” spring removed on the attachment side, then the slot where the cross member fits was excavated for about 1/32”. Expectations were that this would lower the front end of the Woody a scale 1.5”. In just the reverse the rear end was raised a scale 1.5” by removing the pins from part 75 and adding 1/16” longer pins. Overall 3 scale inches of added rake were achieved.

A small disappointment came when attempting to turn the front wheels. The hairpin radius arms (parts 73) would have collided with the wheels in the real car. They are simply mounted to far to the outside of the chassis and have no way to correct this with the kit pieces.

While both building the interior and chassis I was also commencing the painting process on the cars body. First the body and hood where washed (as were the rest of the kit parts to be painted) with warm water and dish soap and then left to air-dry. Next I primed most of the parts using Tamiya white surface primer in a can. The base for the wood frame was then sprayed in Tamiya flat buff acrylic using my Pasche VL1 airbrush. Carefully I masked the wooden exterior trim to expose the wheel wells, front fenders and cowl area. Before painting I sprayed the model with Future to seal the tape seams and prevent any paint bleed. The exposed areas of the kit as well as the spare tire carrier, and internal wheel wells, etc. were then air brushed Model Master Boyd’s’ Orange Pearl. After I removed the masking tape I placed these parts in the dehydrator to dry for two days.

After the paint had fully cured I again sprayed the entire body and hood with future to give a silk like base for applying the fine wood wash, Bare Metal Foil and AMT kit decals. Prior to beginning the decal process I ran a small rusty/oily pin wash through the seams, joints and over the exposed wood to add some realistic wood finish.

The Round 2 decals went on very well only using warm water to get them to slide properly. It is imperative that you trim the door panel wooden decals very close so that they sit perfectly in their respected slots. Go slow and follow the directions/numbers so that you’re fitting the right decal with the correct space. They do look very convincing when done right.

The vinyl tires on the kit are nice big and little Goodyear Eagles with directional tread so some care must be taken when mounting. I used a light airbrush of Tamiya smoke on the wheels chrome to add some need relief to the kit wheels.

As you head into final assembly there are some special things that need to be addressed. The rear side windows must be cut from plain acetate sheet stock. There is a template on the first page of the instructions. I made a copy of this template so that I could cut them out without damaging my directions for later use. These templates were then used to outline the image on the clear acetate and cut the windows out. I installed the windows per the instructions using white glue. With the left over acetate I cut one extra half window to install on the drivers side.

When you get to step 9 of the final assembly the body and chassis finally come together. I added some random decals along the rear windows and lightly sprayed all the chrome trim with Tamiya smoke before installing.

I encountered no problems throughout the entire assembly process with fit, molding quality, or direction of this AMT 41 Ford custom. As you can see by the photos this kit builds into a rather attractive looking vehicle. I can almost feel the sand between my toes and hear the crash of the waves along the Ventura County coastline. Even though it took 25 ½ hours to build, it was all a simple pleasure to assemble with absolutely no headaches. Majority of the time building was used up in the masking and painting process. This kit is highly recommended as a fun build.

Thanks to Round 2 AMT, Dick Montgomery, Dave Morrissette, the rest of the IPMS Reviewer Corp assistants and IPMS/USA for the chance to build and review this subject.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Similar Reviews