AFV Valentine Mk.III w/Rotatrailer

Introduction

I won’t go into the history of the Valentine Tank because each modeler, I’m sure, does his own research before beginning the build. But, what I found interesting was the different opinions as to how the Valentine got its name. One reference implies that the name came from the middle name of Sir John Carden, the designer of the A9 and A10 which were prototypes of the Valentine. Another reference article states that the name came from an acronym of the designer. (Vickers Armstrong Limited Engineers Newcastle-upon-Tyne). Even other references imply that the name came from the date it was introduced to the Army of which was Valentine’s Day, February 14th, 1938. Whatever the reason for the name, the Valentine and its variations continued to be used. As to accuracy of the model, it does appear to be very accurate when compared to some scale line drawings.

The Rota-trailer was a British design intended to carry fuel, water, rations and munitions. Included inside was a hand fuel pump intended to pump fuel into the tank. Pulled behind tanks it eventually proved to be unsatisfactory due to its unreliability. Partly due to the hollow wheels leaking and damage to the ammunition due to it not having springs. This was difficult to maneuver over rocks and the sort. A good reference for the Rota-trailer is the Tank Museum at Bovington.

As this was my first Valentine to be built, I am looking forward to seeing how it actually goes together. I purchased three books to use for reference, but during the build I found out there are many pictures to refer to on the web. Since there are many variations of the Valentine, I can use the reference books for future builds. A very good reference is Taylor, Dick. INTO THE VALLY: the Valentine tank and derivatives 1938-1960. Sandomierz: Stratus, 2012. Print.

Box

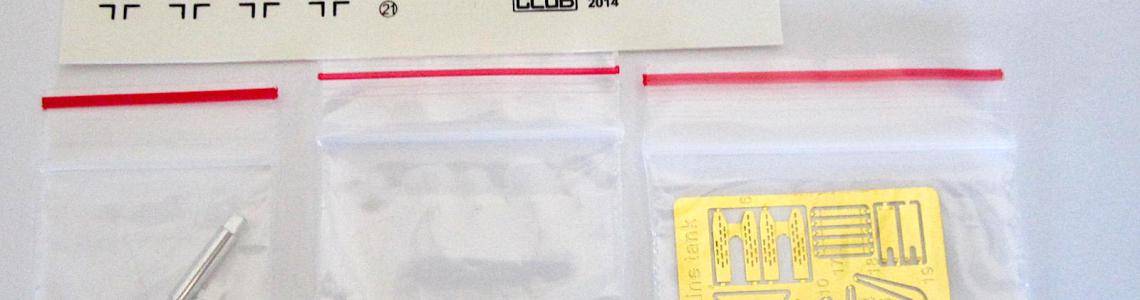

The box is a normal size 15” long x 9-3/4” wide x 2-1/4” tall heavy gauge cardboard containing 10 olive drab sprues, two gray sprues, one clear sprue, one cellophane baggie containing the lower hull, 1 set of vinyl tracks with polycaps attached, one baggie containing two frets of photoetch, one metal barrel, four resin track links and one small decal sheet. Additional items in the box include one twenty-page instruction sheet divided into forty build steps and one large (box size) colored print of the front box art. Nice touch if one wants to frame it for later use.

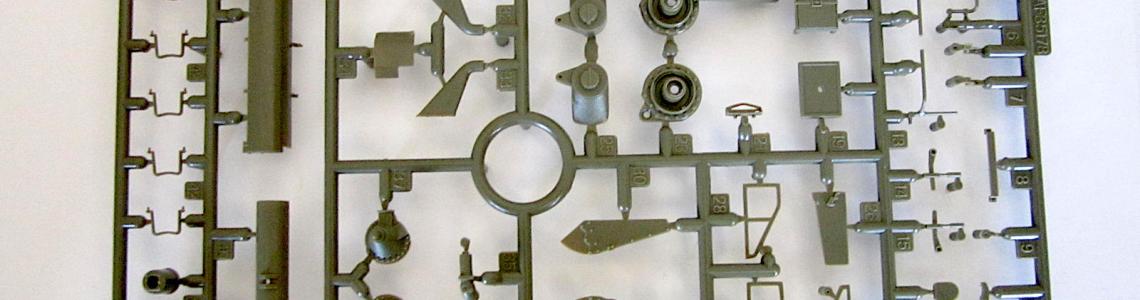

Sprues

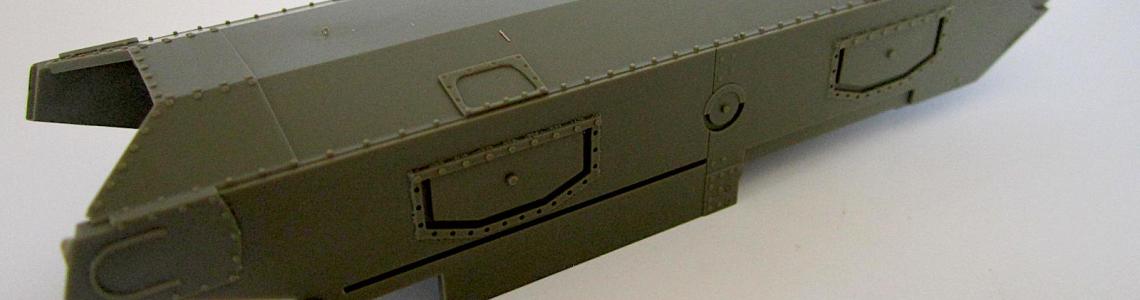

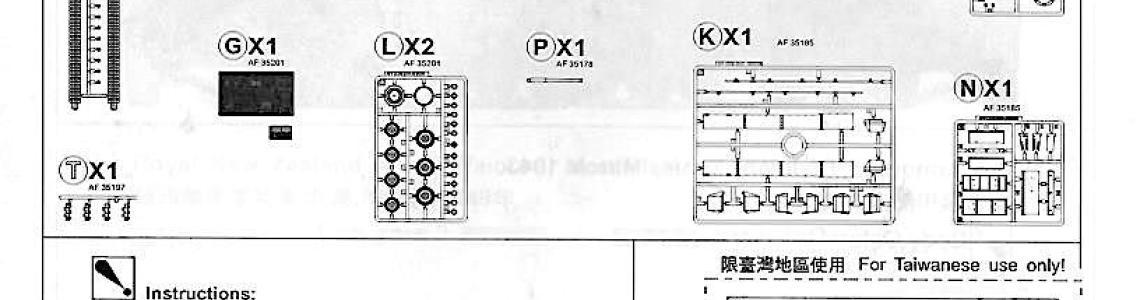

Upon opening any model kit, what I like to look for is the amount of work, such as mold relief tapers, flashing, ejector pin release points (recessed or elevated marks), mold shift points, sprue attachment points and mold seams that need to be addressed during construction. The parts have crisp detail. However, there are several pin release points seen which will have to be sanded or filled. Whether these come into play, I will find out during the construction. The sprues have absolutely zero percent flash and very little seam lines that need to be cleaned up. The attachment points are kept to a minimum and are located in non-discreet areas. AFV in this kit has combined sprues from several kits including Kit # 35178 (Valentine Mk I), Kit# 35185 (Valentine Mk II), Kit # 353153 (Churchhill) and Kit # 35264 (Rotatrailer). With regard to the Rotatrailer, only the external parts are contained within the kit on one sprue. AFV does not provide the internal parts such as; resin parts, photo etch, brass rounds or vinyl tubing that are supplied with their kit # 35264. The box art does state the hatch is workable, so I’m sure for those who want to show the Rotatrailer open, aftermarket parts and scratch building could be added and constructed.

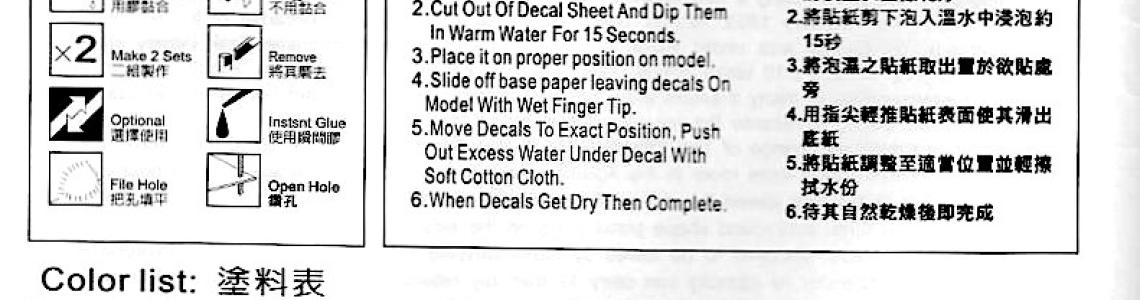

Instruction Manual, Paint/Markings Guide, Decal Sheet

The instruction manual is printed in black and white measuring approximately 8-1/4” x 11-3/4” in a portrait booklet orientation. It contains forty steps on twenty pages of clear uncluttered diagrams. Included within the seventeen pages is the last page (steps 37-40) for the Rotatrailer. Also, included in the instructions are images for the parts layout on the sprues and two pages of markings and painting guides for four vehicles. Additionally, there are paint color references for Gunze Sangyo, Humbrol, Revell and Lifecolor paints. There is plenty of room for notations prior to or during the building stage on the instructions.

In reviewing references, I have decided to build the “Pz.Rgt.7, 10 Panzer Division, DAK, Libya 1942. This version does not have the sand shields installed, however for purposes of this review I will test fit the shields. During the test fit I saw no problems. With that said, I am looking forward to building this tank. Since we modelers do not always follow the instructions step by step, but for the purposes for this review I will describe any irregularities or problems I encountered in the build step by step. Now for the fun process.

The Build

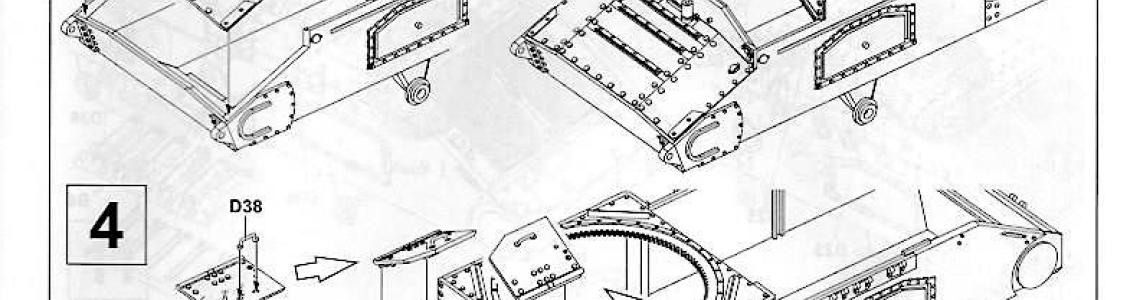

Steps 1 and 2: These steps consist of construction of the hull which is a single tub design. Detail is crisp and clean. Very little cleanup was required. In step one you have a choice of back plates B37 or A2. A2 has a hole for the towing pintle. Also in this step, you are instructed to open 8 holes in the top of the turret base. I’m not sure why because the parts A5, A9 and A11 have small stubs to go into these holes. I decided just to cut off the small alignment pins and glue directly to the hull. Fit of the parts is good. There were some ejector pin release points, but these are inside and will not be seen.

Steps 3, 4, 5 and 6: In these steps part B4 is incorrectly identified as B3 on page 5 of instructions. This doesn’t cause an issue. The drivers hatch has great detail on the inside and outside. Unfortunately, if you want the hatches open the interior must be constructed from scratch. Only the No. 19 radio set and gun breech are provided. Same for the two driver periscopes. They are well detailed but, cannot be seen unless an interior is constructed to leave the hatches open. All that is seen are the front optics of the periscopes. Also in step 4, I decided to wait to install the hatch handles (parts 38) until further along into the build. In step 5 Part B2 is incorrectly identified in the instruction sheet as Part B1. I saw no problem because Part B1 and B2 are installed onto the tank at the same time. Additionally, Part G2 in step 6 is incorrectly identified in the instructions as G5. G5 (photoetch) is actually in step 33.

Step 7: In this step, the modeler must be aware of exactly how the engine deck goes together. Referring to parts B23, B24, B25, B5 and D21 one must test fit these first before any glue is added. I inadvertently glued parts B5 and D21 incorrectly where I found these did not fit after they had dried. Upon further research and referring to walk around pictures, I was able to construct them correctly. How these go together is apparent in AFV Club’s molding of the detail with the hinges. Also In this step is the installation of the lifting handles (Parts D36) on the engine deck doors.

Step 8: This step is the construction of the radiator access doors with the deck louvres. Sub section denoted as (A) does in fact call out the four part numbers B40, B42, D30, D19 however, Sub section(B) only calls out 3 armoured louvres, B41, B39 and D19. Part D30 is not noted on instruction sheet. Also, part B26 in incorrectly identified. It should be B46 which has the hinge plate assembly attached as does B45.

Step 9: Consists of building the racks that held 5-two gallon liquid containers. These are mounted onto the transmission access door. References show exactly how to mount, as there are not any mounting holes on the kit parts. Here I added weld beads to the rack that is attached to the transmission access door. Additionally, in this step, I decided to wait to attach the pintle mount until I constructed the Rotatrailer.

Steps 10-13: Consist of constructing all the wheel assemblies with polycaps, idler supports and drive sprockets. The track adjuster mechanism is well detailed. The use of the polycaps will be invaluable later on during the painting process. The ridged outer drums of the drive sprocket assembly are detailed with a small seam that has to be removed. This may come into view after final assembly. Also note that in Step 13 wheel Part L4 (Subsection H) is incorrectly identified as L3. It is apparent upon close inspection due to the size difference. From references the bolt pattern is spot-on, on both the small and large diameters wheels.

Steps 14-18: Consist of construction of the articulated suspension system using the design of British engineer Sidney Horstmann and attachment of the wheels. With the use of the polycaps the wheels can be removed for painting. Review of this design is well worth the time to read. There are several sources for review. In viewing the parts needed for the construction, the detail is well represented including, but not limited to small weld beads. The springs, to this reviewer, are unbelievably well molded. I did find some flash on part D6 but, very little.

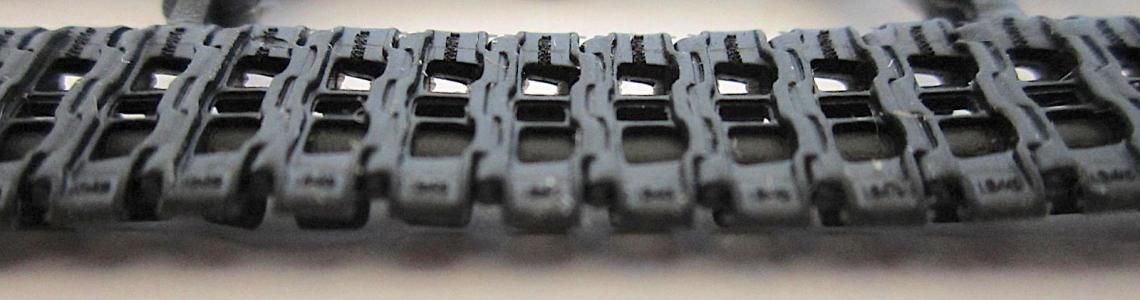

Steps 19-20: Consist of attaching the tracks using CA glue and drill several holes in both side fenders (C4 and C47). The instructions do not specify the size of the holes to drill, but I found that a 0.8mm diameter drill bit was sufficient. The tracks are stamped with two guide horns per link which were required due to the single roadwheels. Detail is crisp and approximates historical track pictures. Clean up was very little. Gluing the tracks together did present a major problem. CA glue did not work. I tried other brands of CA glue, epoxy and different brands of model glue. Nothing worked. I finally had to resort to stapling the tracks together and hoping the staple would be hidden by the sand skirts. There are several aftermarket metal and plastic tracks available which could be substituted for the kit vinyl tracks. Upon dry fitting the sand skirts, I was correct. The staple is hidden from view.

Steps 21-23: Consist of the attachment of side sand shields, fenders and photoetch supports along with removal of 22 bolt heads on fender C4. Depending on which decal markings version one chooses decides which steps to use.

Steps 24-28: Consist of attaching the small accessories to the upper hull such as muffler, pioneer tools, and the like. The pioneer tools were well detailed. Also in step 27 is the placement of the resin tracks(T) to the fenders. There are several injection molding relief points that will have to be removed as these will be seen. I’m not quite sure why the resin links are supplied because plastic links are also on sprue A with same detail as far as I could see.

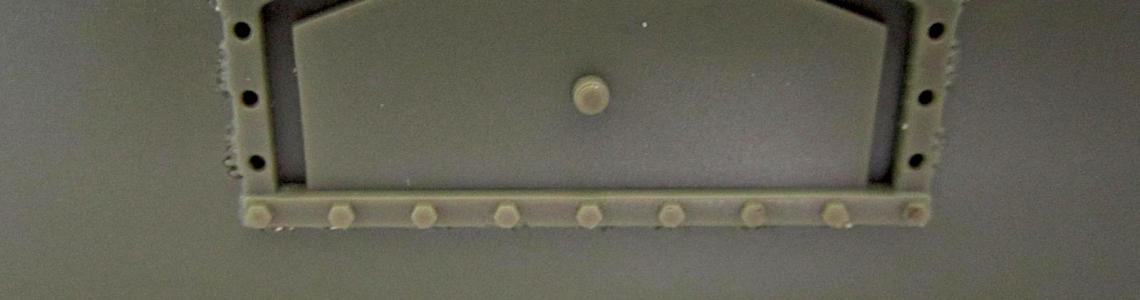

Step 29-34: Consist of construction of the 2 pounder (40mm) main gun, gluing together the turret, installation of the No. 19 radio set, and Besa 7.92mm machine gun along with attaching several small parts to the turret. The machine gun is slide-modeled therefore no drilling is necessary. A polycap is used for the main gun, bu, the part number is not specified. Also in step 30, AFV Club has provided bolt heads to be placed on the mantlet. A nice touch. These are located on the back of the sprue B. AFV Club provides an aluminum barrel which dimension-wise seems to be correct. Note the turret ring B15 is not noted on instruction sheet. The pistol ports are well detailed and can be left open or closed. Part number B9 is incorrectly identified on instruction sheet as B6. Should be B9.

Step 35-36: Consist of construction of the Mk2 Bren machine gun, attachment of the headlights and antenna aerial. AFV does include the length of the aerial at 2cm. The machine gun is slide molded and comes with either the 100-round drum magazine or banana magazine.

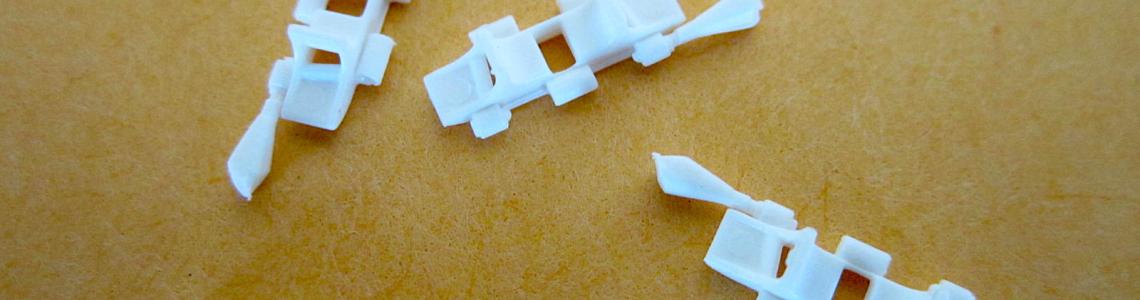

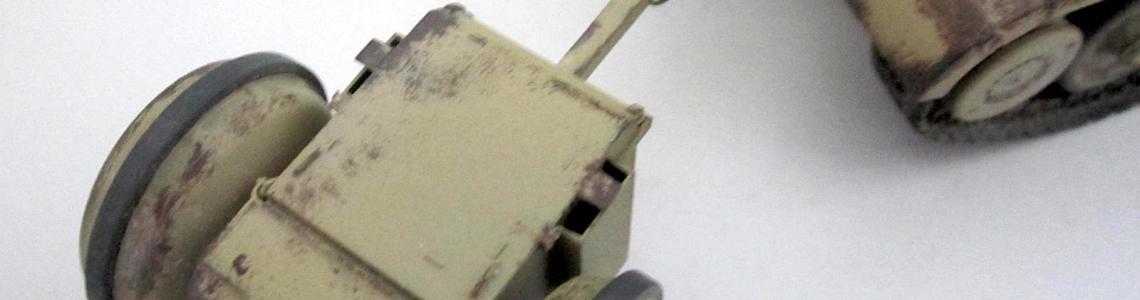

Steps 37-40: Consist of construction of the Rotatrailer. There are several ejector pin release points on parts A8, A9 and A10 that will have to be filled if the model is intended to be shown open. No fit issues were noted and detail is well molded. One has the options of having the access doors open or closed. If left open there are quite a few ejector release points that need to be removed.

Painting and Decals

After an initial primer coat of Vallejo’s German Red Brown 73.605, the model was given two coats of a mixture closely representing Khaki Green #3. After this a final finish coat of A. Mig’s Ral 7028 Dunkelgelb 011 was applied. Before the decals were applied, I sprayed on a coat of gloss varnish. The decals were then applied using Microset and Microsol. I saw no real issue with the decals. They went down extremely well with silvering nonexistent. Pin washing and weathering was then accomplished by using several different pigments and paints.

In Conclusion

After completing each kit, I ask myself, “would I build this kit again?” In regards to this kit, my answer is “most certainly yes”. Probably one of the other variations though by AFV Club. One particular item I did notice while building this kit was that the grey sprues were harder and more brittle compared to the other sprues. This didn’t cause problems but, cutting was more difficult. This definitely was an enjoyable build. Good references are a must if this is your first Valentine tank. If it is not, then the order of construction is apparent.

Thanks to IPMS/USA and Hobbyfan for allowing me to review this kit.

Comments

Add new comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.